Lithium battery positive pole piece and preparation method thereof

A positive pole piece, lithium battery technology, applied in the direction of battery electrodes, electrode manufacturing, secondary batteries, etc., can solve the problems of active coating current collector peeling off, battery failure, etc., to facilitate fixation and charge and discharge cycles, improve capacity, good synergistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

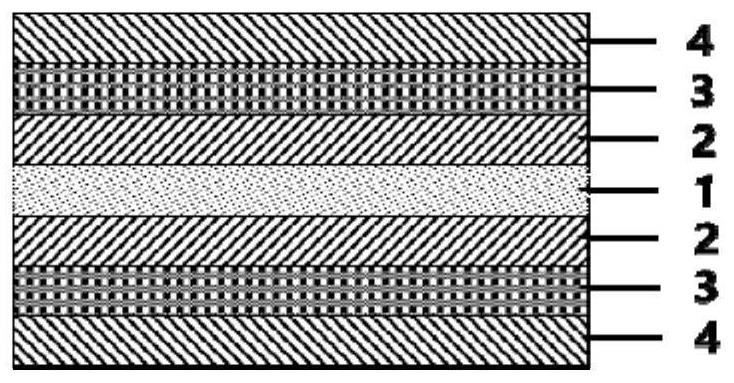

[0054]This embodiment provides a positive electrode plate of a lithium battery, the structure of which is as follows figure 1 As shown, it includes a current collector 1 located in the inner layer of the positive electrode sheet, and a first coating layer 2, a conductive carbon cloth layer 3 and a second coating layer 4 which are arranged symmetrically outward from both sides of the current collector in sequence.

[0055] The preparation method of the positive electrode is as follows:

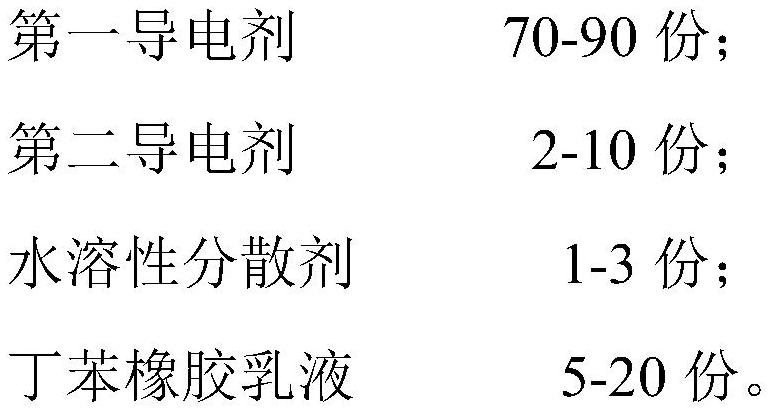

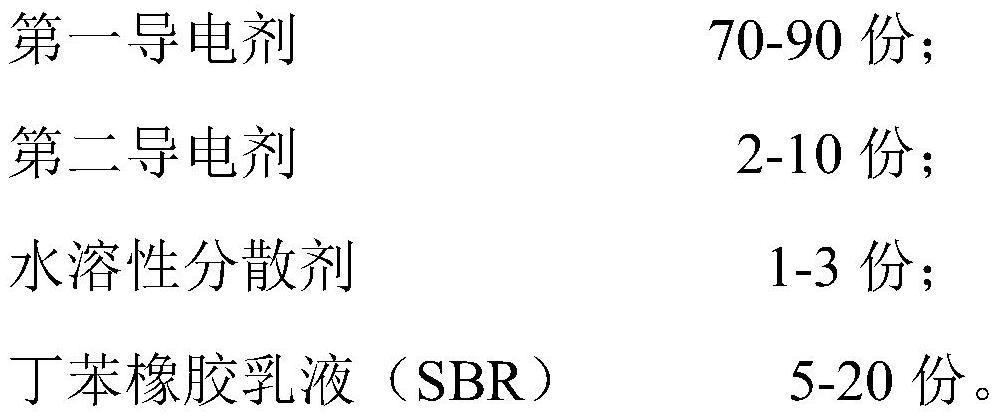

[0056] 1. Preparation of composite slurry: the first conductive agent (high specific surface area porous activated carbon), the second conductive agent (carbon black), water-soluble dispersant (carboxymethyl cellulose sodium salt) and styrene-butadiene rubber emulsion (SBR) ) mix according to the mass ratio of 85:5:1:9, use deionized water as the solvent, adjust the solid content to 20wt%, use a high-speed mixer to mix to form a stable and uniform slurry, the stirring speed is 2000rmp, and the ...

Embodiment 2

[0063] This embodiment provides a positive electrode plate of a lithium battery, the structure of which is as follows figure 1 As shown, it includes a current collector 1 located in the inner layer of the positive electrode sheet, and a first coating layer 2, a conductive carbon cloth layer 3 and a second coating layer 4 which are arranged symmetrically outward from both sides of the current collector in sequence.

[0064] The preparation method of the positive electrode is as follows:

[0065] 1. Preparation of composite slurry: the first conductive agent (porous activity with high specific surface area), the second conductive agent (carbon black), the water-soluble dispersant (carboxymethyl cellulose sodium salt) and the styrene-butadiene rubber emulsion (SBR) ) mix according to the mass ratio of 78:10:2:10, use deionized water as the solvent, adjust the solid content to 16wt%, use a high-speed mixer to mix to form a stable and uniform slurry, the stirring speed is 2000rmp, ...

Embodiment 3

[0072] This embodiment provides a positive electrode plate of a lithium battery, the structure of which is as follows figure 1 As shown, it includes a current collector 1 located in the inner layer of the positive electrode sheet, and a first coating layer 2, a conductive carbon cloth layer 3 and a second coating layer 4 which are arranged symmetrically outward from both sides of the current collector in sequence.

[0073] The preparation method of the positive electrode is as follows:

[0074] 1. Preparation of composite slurry: the first conductive agent (high specific surface area porous activated carbon), the second conductive agent (carbon black), water-soluble dispersant (carboxymethyl cellulose sodium salt) and styrene-butadiene rubber emulsion (SBR) ) mix according to the mass ratio of 90:2:2:6, use deionized water as the solvent, adjust the solid content to 12wt%, use a high-speed mixer to mix to form a stable and uniform slurry, the stirring speed is 2000rmp, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com