Low-temperature diffusion welding method for magnesium alloy and aluminum alloy

A technology of diffusion welding and magnesium alloy, which is applied in the field of welding of magnesium alloy and aluminum alloy, and low temperature diffusion welding of magnesium alloy and aluminum alloy. Reliable and precise welding, the effect of improving joint strength and bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

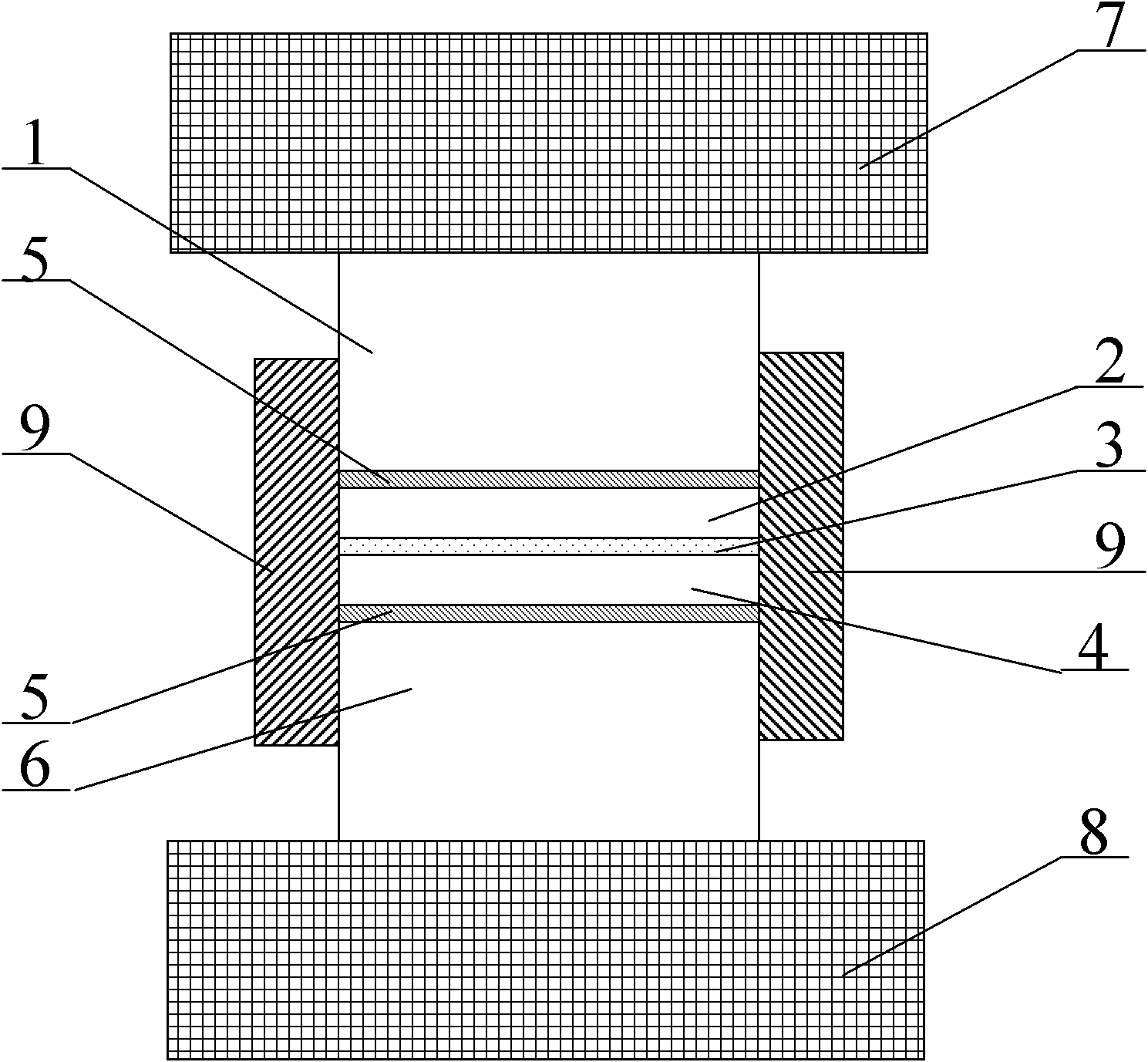

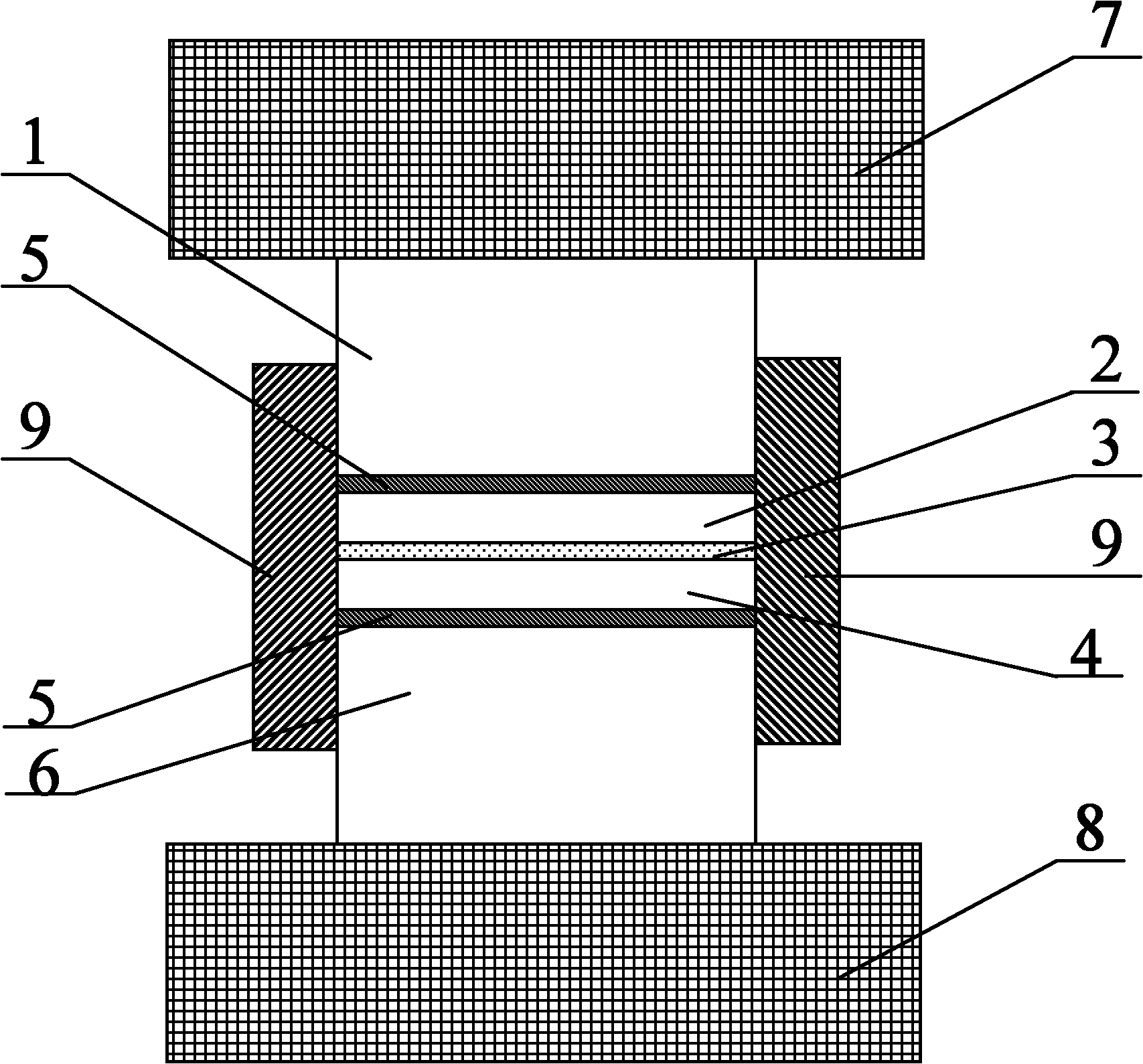

[0026] The magnesium alloy sheet 4 is diffusion-connected to the aluminum alloy sheet 2, wherein: the magnesium alloy sheet 4 is a MB2 magnesium alloy sheet with a diameter of Φ29 mm, and the aluminum alloy sheet 2 is a 2A12 aluminum alloy sheet with a diameter of Φ29 mm. Diffusion bonding process conditions are: welding temperature 400 ℃, holding time 60min, welding pressure 0.1MPa.

[0027] The specific steps of diffusion bonding the magnesium alloy sheet 4 and the aluminum alloy sheet 2 are as follows:

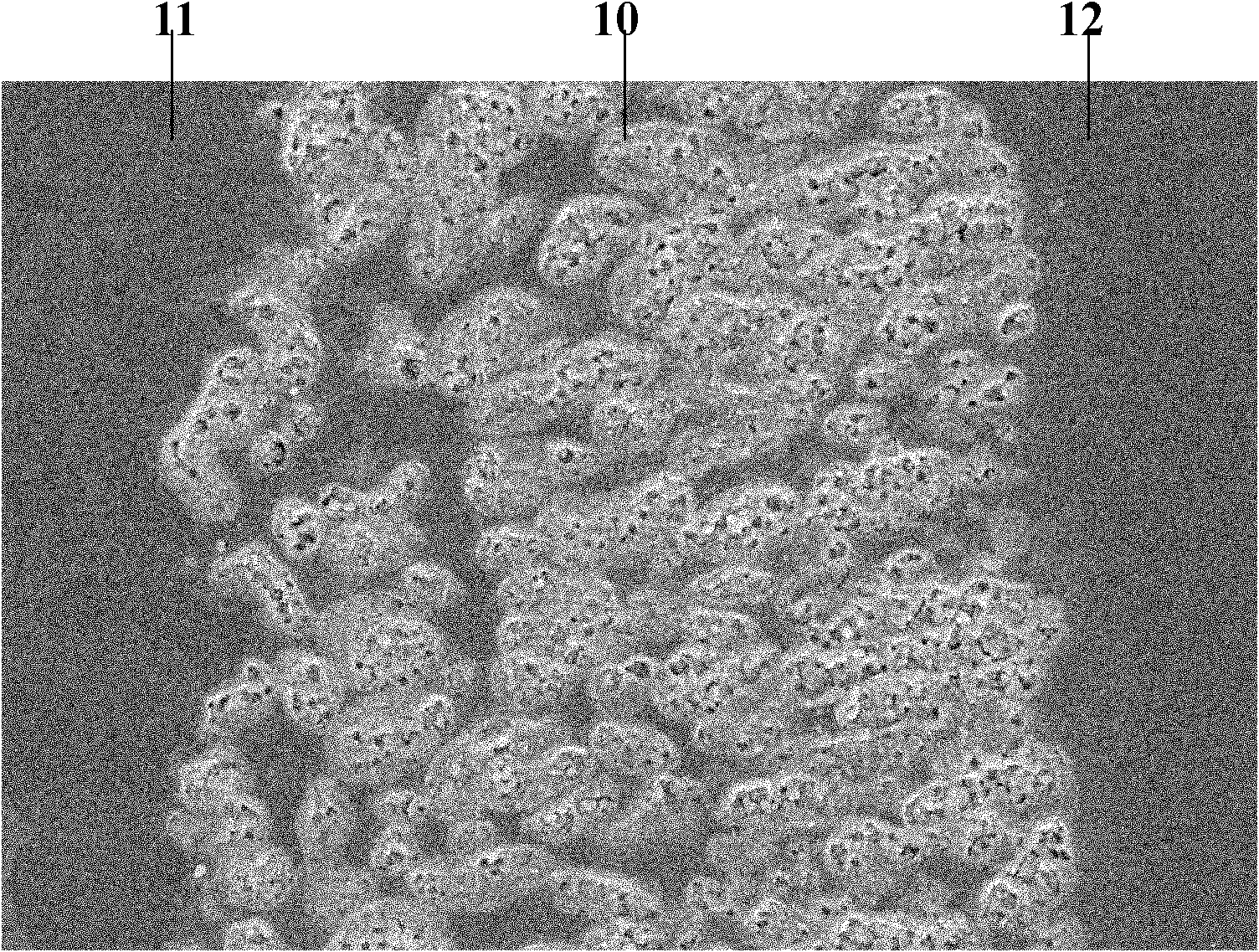

[0028] Preparation before welding: The middle layer material is tin-zinc foil 3 with a thickness of 5 μm (Sn / Zn ratio is 1: 1), and the tin-zinc foil 3 is processed into a disc with the same diameter as the magnesium alloy sheet 4 and the aluminum alloy sheet 2, Ultrasonic cleaning with acetone solution for 10 min. Use a surface grinder to process the magnesium alloy sheet and aluminum alloy sheet into a round sheet with a parallelism better than 0.05mm. Before welding, us...

Embodiment 2

[0032] The magnesium alloy sheet 4 is diffusion-connected to the aluminum alloy sheet 2, wherein: the magnesium alloy sheet 4 is a MB2 magnesium alloy sheet with a diameter of Φ29 mm, and the aluminum alloy sheet 2 is a 2A12 aluminum alloy sheet with a diameter of Φ29 mm. Diffusion bonding process conditions are: welding temperature 450 ℃, holding time 10min, welding pressure 1 MPa.

[0033] The specific steps of diffusion bonding the magnesium alloy sheet 4 and the aluminum alloy sheet 2 are as follows:

[0034] Preparation before welding: the middle layer material is tin-zinc foil 3 with a thickness of 30 μm (Sn / Zn ratio is 1: 9), the tin-zinc foil 3 is processed into a disc with the same diameter as the magnesium alloy sheet 4 and the aluminum alloy sheet 2, Ultrasonic cleaning with acetone solution for 10 minutes; use a surface grinder to process the magnesium alloy sheet and aluminum alloy sheet into a round sheet with a parallelism better than 0.05mm, and grind the round...

Embodiment 3

[0038] The magnesium alloy sheet 4 and the aluminum alloy sheet 2 are diffusion-bonded, wherein: the magnesium alloy sheet 4 is an AZ31B magnesium alloy sheet with a diameter of Φ29mm, and the aluminum alloy sheet 2 is a Φ29mm 1060 aluminum alloy sheet. Diffusion bonding process conditions are: welding temperature 400 ℃, holding time 30min, welding pressure 0.5MPa.

[0039] The specific steps of diffusion bonding the magnesium alloy sheet 4 and the aluminum alloy sheet 2 are as follows:

[0040]Preparation before welding: the middle layer material is tin-zinc foil 3 with a thickness of 50 μm (Sn / Zn ratio is 1: 5), the tin-zinc foil 3 is processed into a disc with the same diameter as the magnesium alloy sheet 4 and the aluminum alloy sheet 2, Ultrasonic cleaning with acetone solution for 10 minutes; use a surface grinder to process the magnesium alloy sheet and aluminum alloy sheet into a round sheet with a parallelism better than 0.05mm, and grind the round sheet with 1000#, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com