Chemical polishing liquid and polishing method

A technology of chemical polishing and brightener, applied in the direction of chemical instruments and methods, polishing compositions, etc., can solve the problems of endangering human health and polluting the environment, and achieve the effects of reducing pollution, high brightness, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

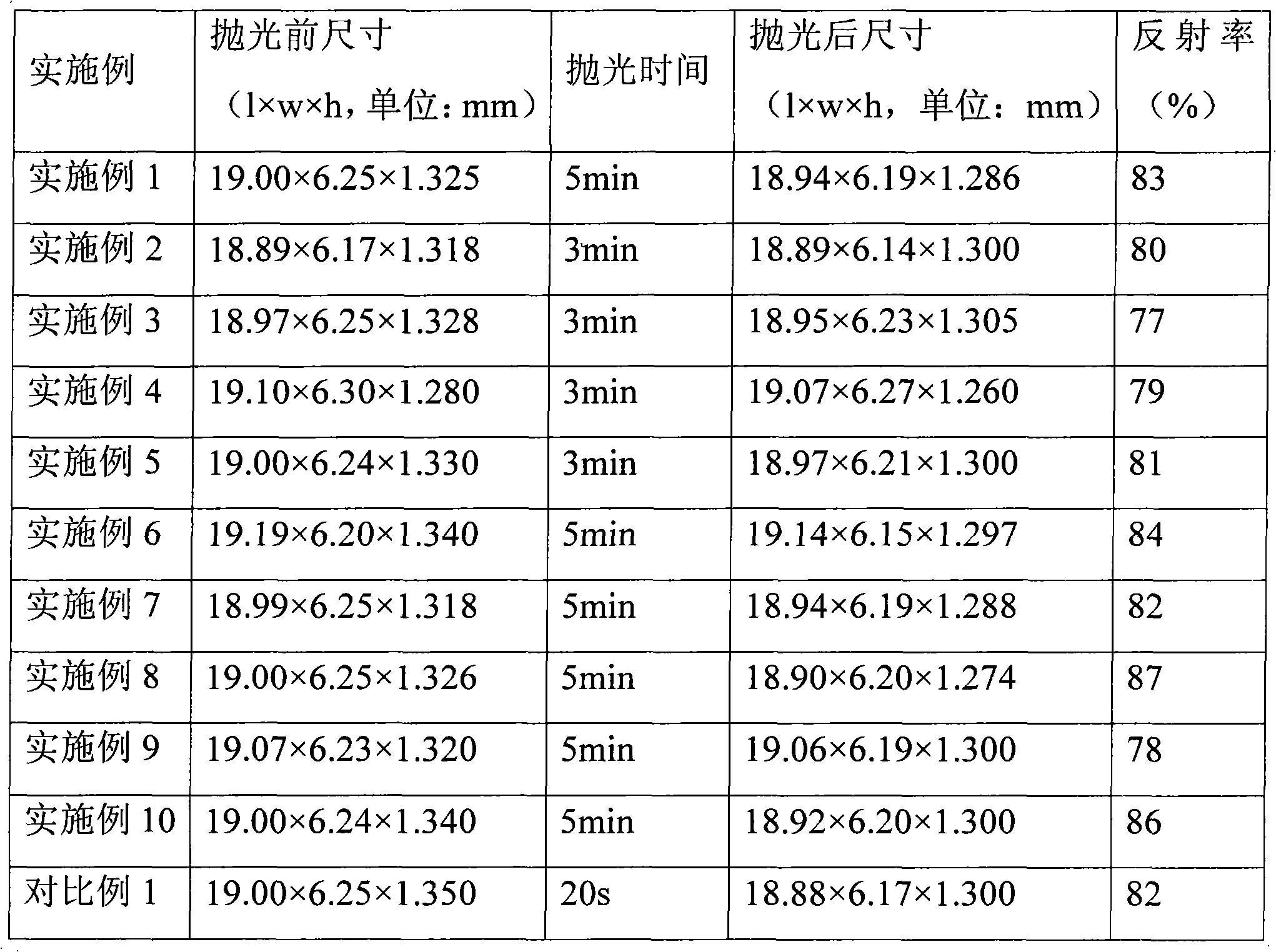

Examples

Embodiment 1

[0029] 1. Prepare chemical polishing fluid according to the following components:

[0030] Sulfuric acid 50ml / L, hydrogen peroxide 150ml / L, acetic acid 150ml / L, phosphoric acid 80ml / L, thiourea 2g / L, benzotriazole 1g / L, acetanilide 150ml / L, add water to 1 liter, the measured pH is 2.1.

[0031] 2. Pretreatment process

[0032] Product inspection: measure the size of the copper-zinc alloy workpiece and mark it accordingly.

[0033] Top piece: Fix the copper-zinc alloy workpiece on the hanger for use.

[0034] Degreasing and degreasing: The copper-zinc alloy workpiece (size before polishing: 19.00mm×6.25mm×1.325mm) is sequentially subjected to all-purpose degreasing (10% all-purpose degreasing agent, treatment for 1min), electrolytic degreasing (60g / L degreasing agent, 45°C, treatment for 30s), acid degreasing (20% acid degreasing agent + 3% phosphoric acid, treatment for 1min), after treatment to remove the grease and dirt on the surface.

[0035] Triple water washing: Put ...

Embodiment 2

[0048] 1. Prepare chemical polishing fluid according to the following components:

[0049] Sulfuric acid 15ml / L, hydrogen peroxide 180ml / L, acetic acid 200ml / L, tripolyphosphoric acid 80ml / L, zinc dihydrogen phosphate 2g / L, nonylphenol polyoxyethylene ether 3g / L, glycerol 200ml / L, imidazole 20ml / L, sodium oxalate 80ml / L, add water to 1 liter, the measured pH is 1.9.

[0050] 2. After pretreatment, immerse the copper-zinc alloy sample in the polishing solution at room temperature (25°C) for 3 minutes, shake the copper-zinc alloy slightly, take out the sample and immerse it in dilute sulfuric acid solution for 10 seconds, rinse with water after acidification to remove the film, Dry to obtain mirror polished effect samples.

[0051]The specific technological process of the chemical polishing experiment is the same as that in Example 1, and the size of the copper-zinc alloy workpiece before polishing is 18.89mm×6.17mm×1.318mm.

Embodiment 3

[0053] 1. Prepare chemical polishing fluid according to the following components:

[0054] Sulfuric acid 70ml / L, hydrogen peroxide 200ml / L, acetic acid 150ml / L, citric acid 60ml / L, coumarin 2g / L, sulfonamide 2g / L, polyoxyethylene fatty amine 100ml / L, benzotriazole 15ml / L , lignosulfonic acid 50ml / L, add water to 1 liter, the recorded pH is 1.9.

[0055] 2. After pretreatment, immerse the copper-zinc alloy sample in the polishing solution at room temperature (25°C) for 3 minutes, shake the copper-zinc alloy slightly, take out the sample and immerse it in dilute sulfuric acid solution for 10 seconds, rinse with water after acidification to remove the film, Dry to obtain mirror polished effect samples.

[0056] The specific technological process of the chemical polishing experiment is the same as in Example 1, and the size of the copper-zinc alloy workpiece is the standard workpiece size of 18.97mm×6.25mm×1.328mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com