Method for manufacturing copper aluminium composite tubing and copper aluminium tubing produced thereby

A copper-aluminum composite and pipe technology, which is applied in the direction of manufacturing tools, pipes/pipe joints/pipes, pipes, etc. and other problems, to achieve excellent reprocessing performance, excellent mechanical properties, and the effect of eliminating thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The manufacturing method of the present invention and the copper-aluminum composite pipe produced according to the method will be further described below through the following specific embodiments, so that those skilled in the art can have a more detailed understanding of the technical solutions and features of the present invention to achieve its purpose.

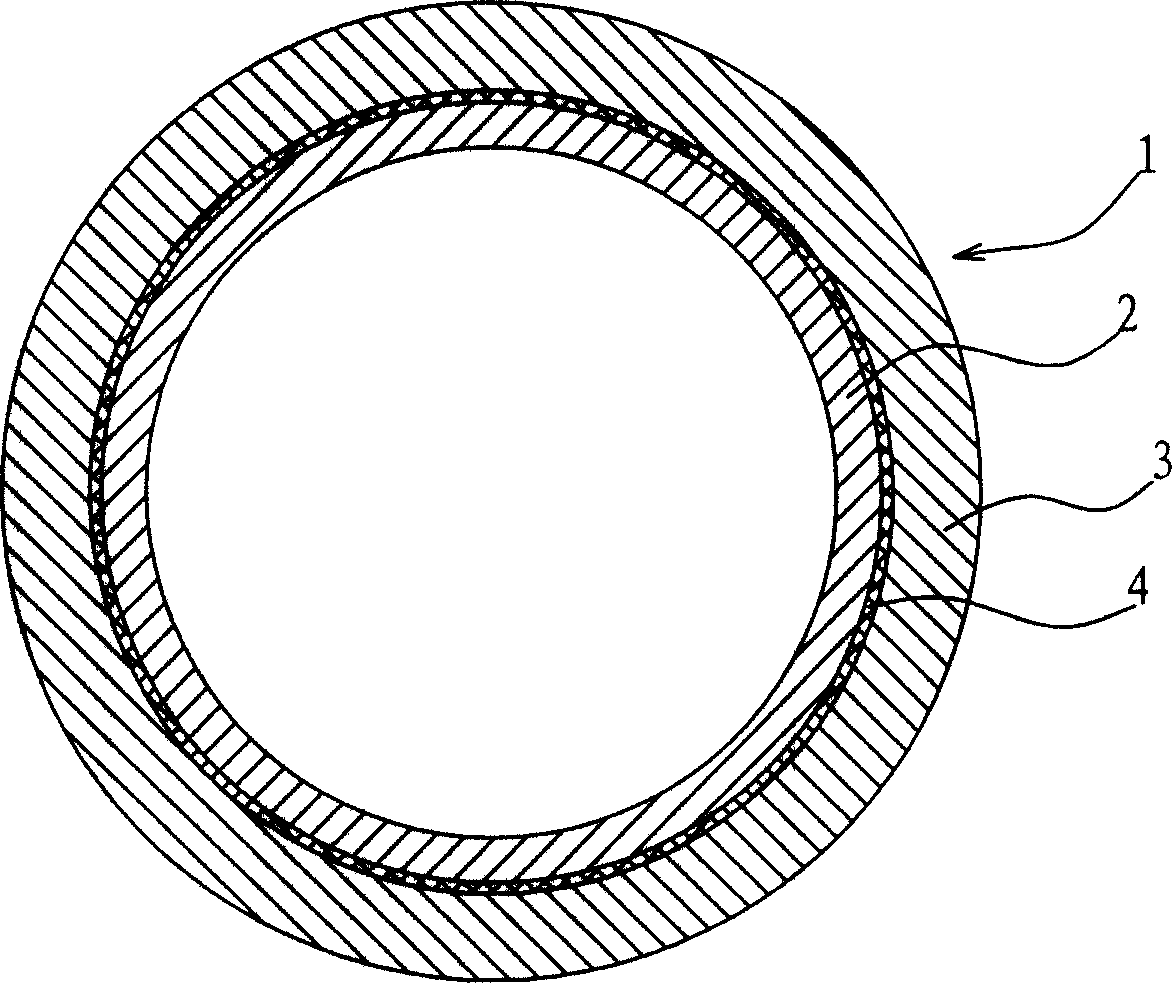

[0037] A preferred embodiment of the present invention is a composite pipe made of rolled oxygen-free copper (T2) and pure aluminum (1060), and the copper inner layer. The rolling is carried out on a commercially available XR-SG90 three-roll planetary pipe mill. The copper-aluminum composite tube billet is compositely cast by the horizontal continuous casting method. The tube billet specification is Φ83×20.5mm, the thickness of the copper layer is 2.5mm, the thickness of the aluminum layer is 18mm, the length is 20m, and the billet weight is 260kg. Composite single-pass rolling is performed by XR-SG90 three-roll pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com