Manipulator conveying device used for automatic detection of commutator

A technology of automatic detection and transmission device, which is applied in the direction of conveyor objects, transportation and packaging, can solve problems such as easy fatigue, and achieve the effect of satisfying transportation and transmission, novel structure and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

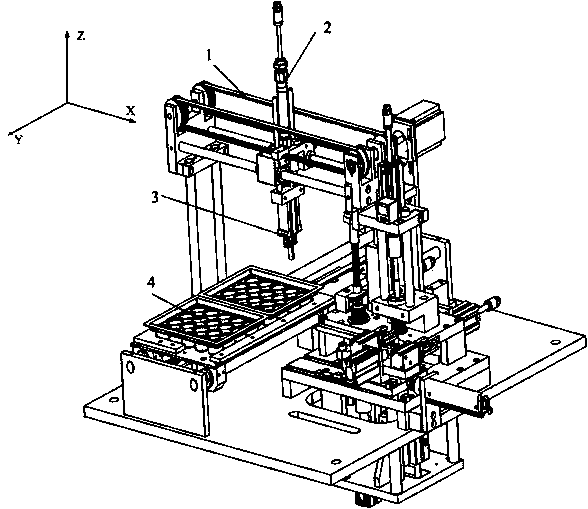

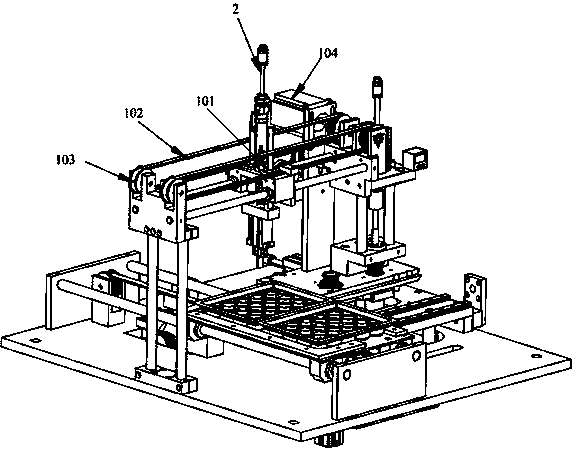

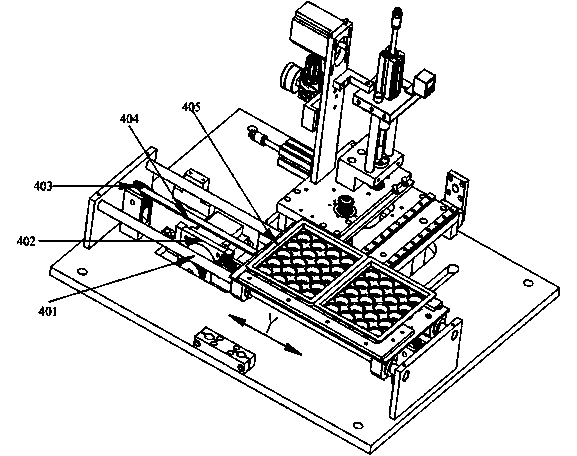

[0017] Such as figure 1 As shown, the manipulator transmission device for automatic detection of commutators includes X-axis transmission unit 1, Y-axis transmission unit 4 and Z-axis transmission unit 2. Y-axis transmission unit 4 includes Y-axis synchronous belt and controls the movement of Y-axis synchronous belt The Y-axis motor, the X-axis transmission unit 1 is located above the Y-axis transmission unit 4, the X-axis transmission unit 1 includes the X-axis synchronous belt and the X-axis motor that controls the movement of the X-axis synchronous belt, and the Z-axis transmission unit 2 is installed on the X-axis transmission On the X-axis timing belt of the unit, the Z-axis transmission unit 2 includes the Z-axis slide rail and the cylinder that controls the movement of the Z-axis slide rail. The clamping hand 3 is installed on the Z-axis slide rail, and the Y-axis transmission unit 4 is on the Y-axis timing belt. A Y-axis motion platform is arranged, and the Y-axis moti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com