Electric motor

A technology of electric motors and brushes, which is applied in the field of electric motors, and can solve the problems of increasing the size of the armature shaft direction and reducing the space factor of the windings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] Hereinafter, an embodiment of the present invention will be described. In addition, in the drawings corresponding to the following description, a part of the reference numerals indicating the common structure in the plurality of embodiments may be omitted.

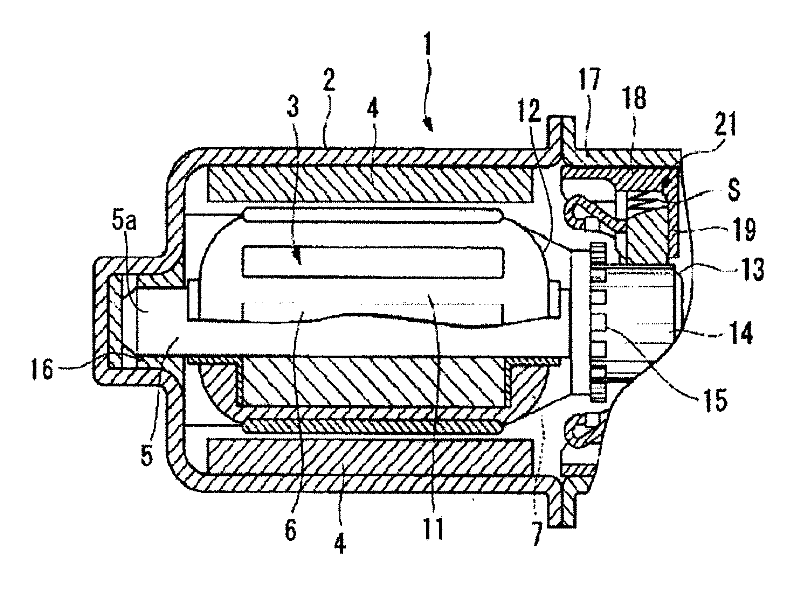

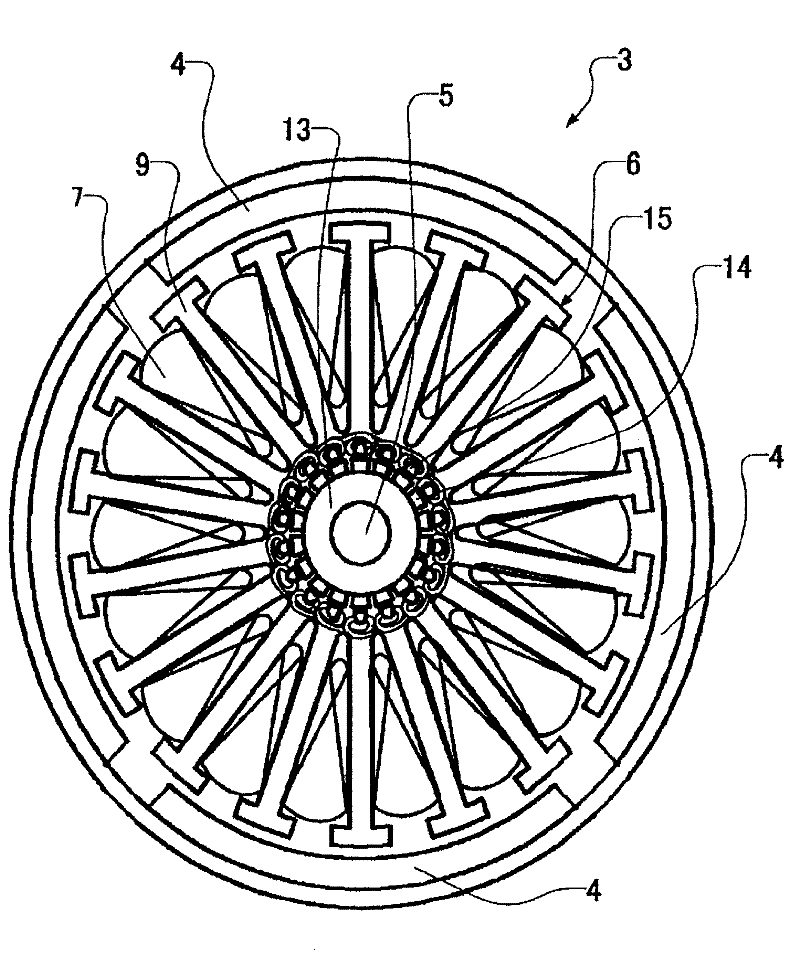

[0078] Then, based on Figure 1 to Figure 5 The motor 1 according to the first embodiment of the present invention described is used as a drive device for a wiper motor, a window motor, a fan motor, etc. of an automobile, for example, and has: a bottomed cylindrical yoke 2; The magnet 4 is fixed on the inner wall of the yoke 2; and the armature 3 is surrounded by the magnet 4 and arranged in the yoke 2, and is supported so as to be rotatable relative to the yoke 2. The magnet 4 is magnetized to 4 poles, and the motor 1 is a 4 pole type motor, and the number of pole pairs is two.

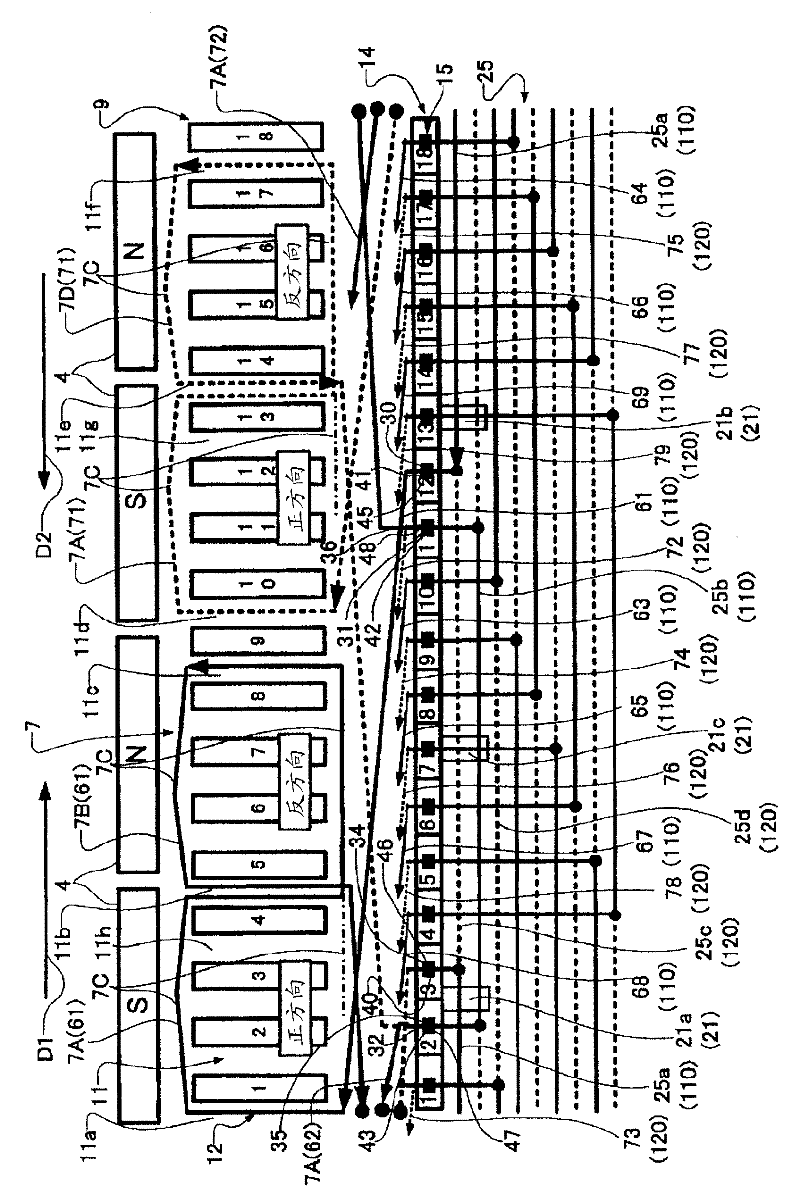

[0079] The armature 3 is configured to include: an armature iron core 6 fixed on the rotating shaft 5; an armature coil 7 wound on the armat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com