Zero-crossing point commutator and zero-crossing point commutation control method for permanent magnet brushless DC motor

A permanent magnet brushless DC, zero-crossing technology, applied in the direction of electronically commutated motor control, control system, monitoring commutation, etc., can solve the problems of high rotor speed, lower system reliability, and magnetic pole distribution errors, etc., to achieve Strong environmental adaptability, easy control of speed, and increased reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

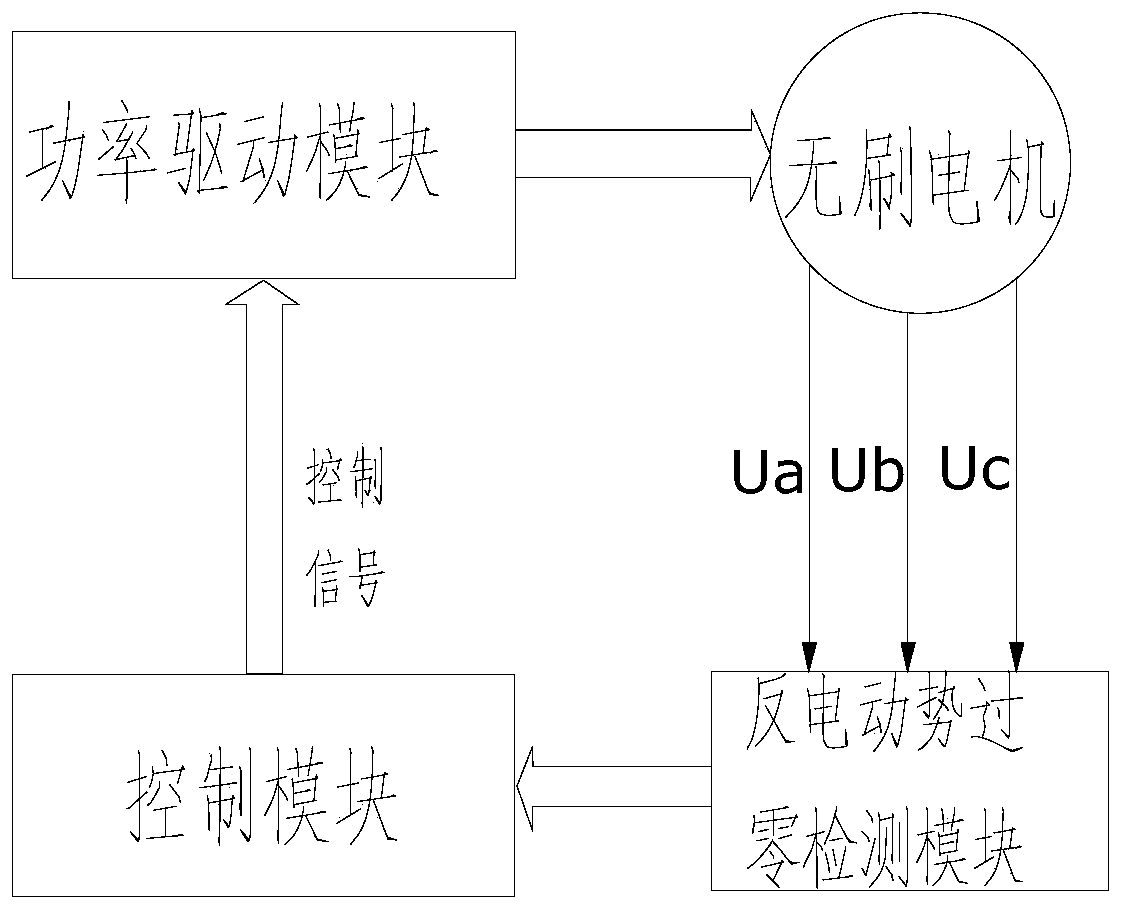

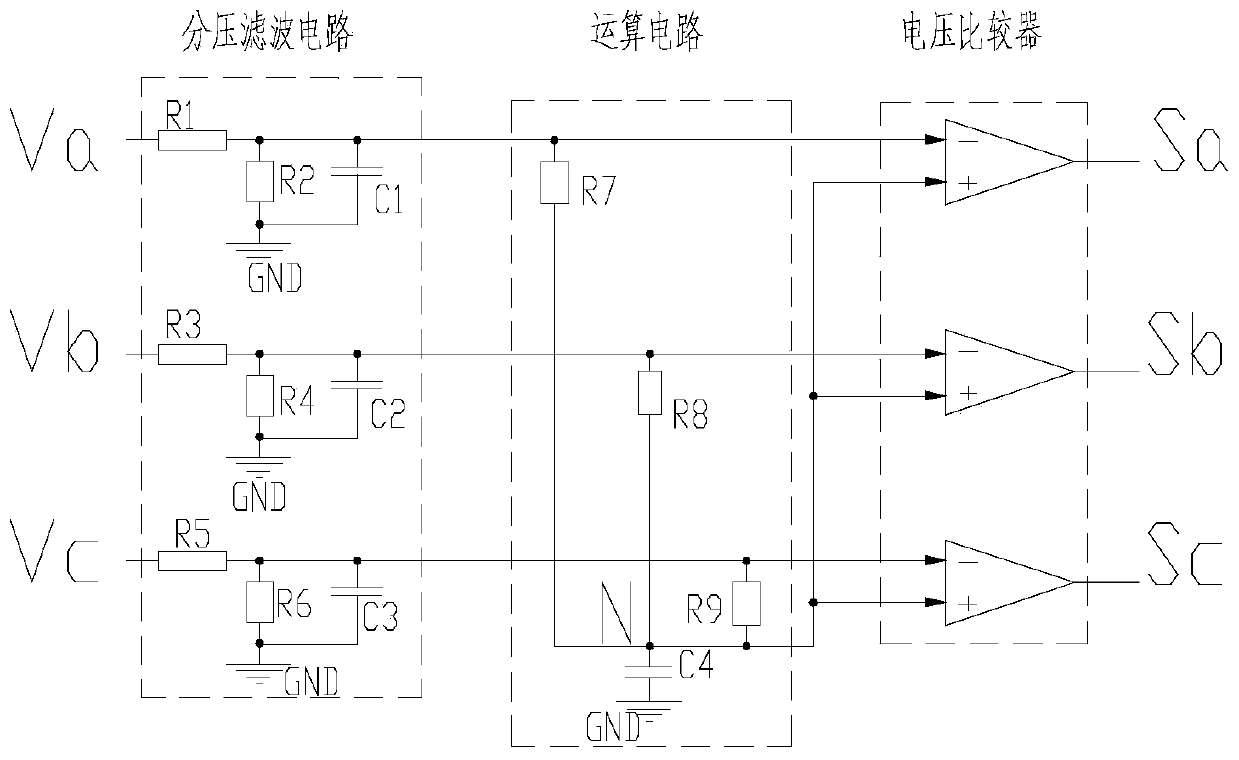

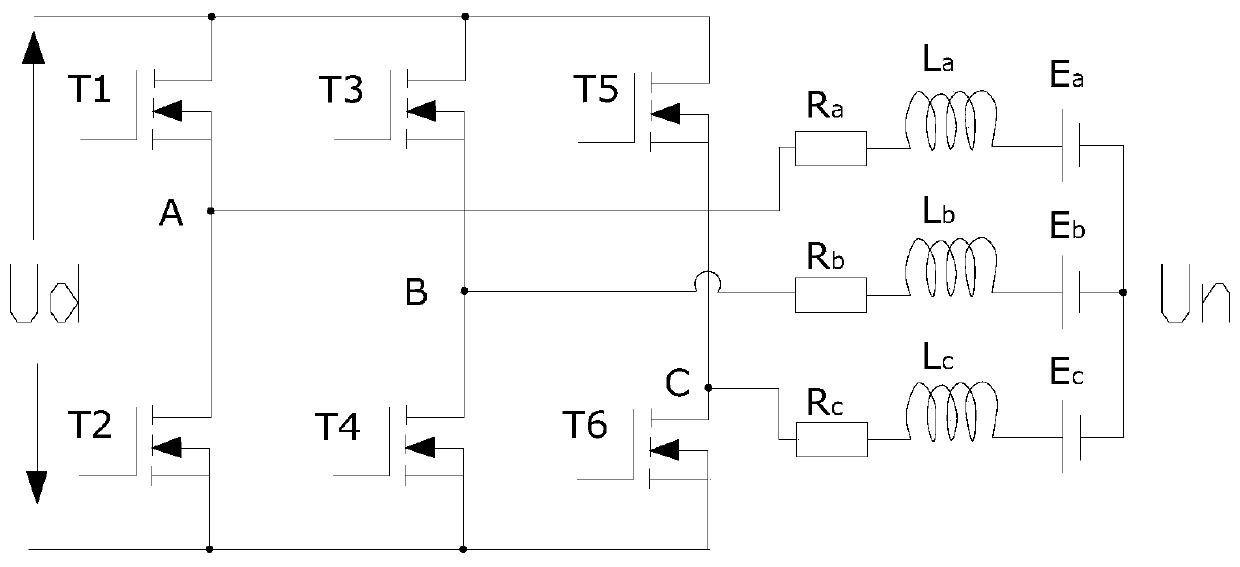

[0032] like figure 1 As shown, it is a zero-crossing commutator of a permanent magnet brushless DC motor of the present invention, which includes a counter electromotive force detection module, a control module, and a power drive module that are electrically connected in sequence; wherein, the counter electromotive force detection module is used for Obtain the stator voltage information of the permanent magnet brushless DC motor to detect the zero-crossing signal of the back electromotive force;

[0033] The control module is used to determine the optimal commutation point according to the back electromotive force zero-crossing signal, and output a PWM control signal to the power drive module;

[0034] Specifically, the control module takes the Stm32 single-chip microcomputer as the core, uses the on-chip AD to directly sample the three-phase terminal voltage of the motor, and judges the zero-crossing point of the reverse electromotive force of the levitation phase through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com