Integrated rotor assembly center

A rotor and assembly mechanism technology, which is applied in the direction of assembly machines, manufacturing stator/rotor bodies, metal processing equipment, etc., can solve the problems of backward production methods, large floor space, large flow range, etc., so as to improve production efficiency and occupy an area Small area, guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

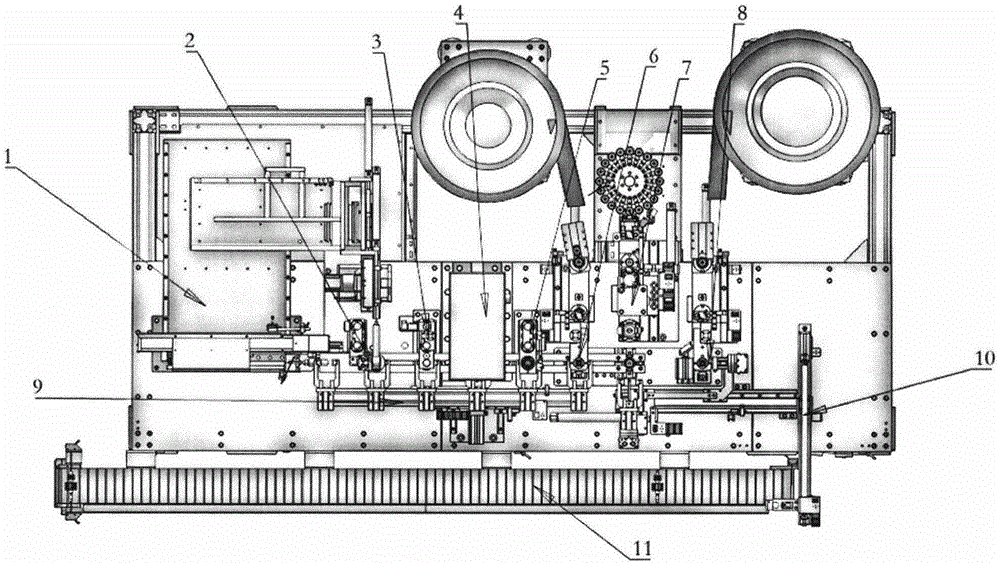

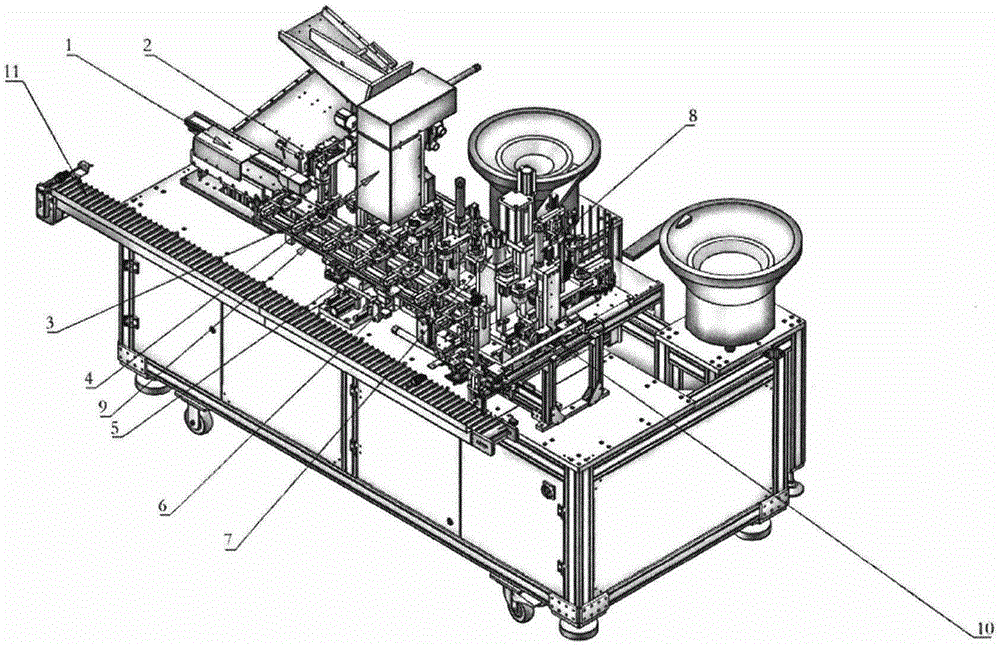

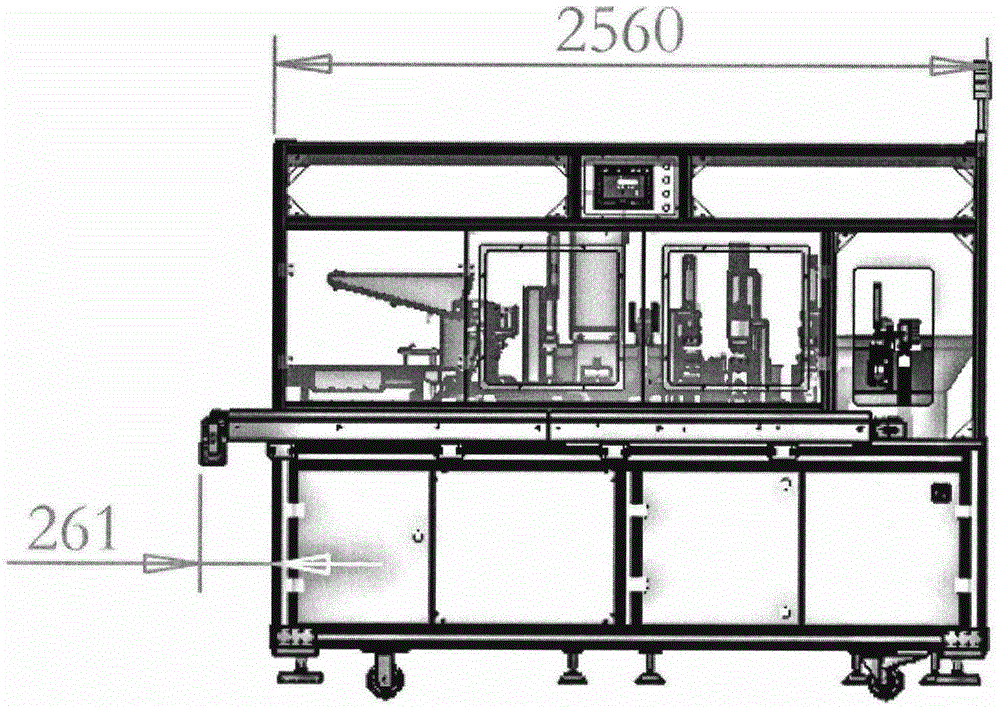

[0025] figure 1 It is a plane view of an integrated rotor assembly center of the present invention; figure 2 It is a three-dimensional view of an integrated rotor assembly center of the present invention; wherein, the rotor core storage and feeding mechanism 1, the rotor shaft storage and inspection and shaft assembly mechanism 2, the core thickness inspection mechanism 3, the final shaft mechanism 4, the core Trunk centering mechanism 5, end cover storage and feeding, positioning and pressing mechanism 6, rotor commutator storage and feeding, positioning and pressing assembly mechanism 7, bottom cover storage and feeding, positioning and pressing mechanism 8, station connection Material shifting manipulator 9, station connection and finished product receiving mechanism hand 10, material receiving conveyor belt 11, the above-mentioned units are installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com