A pure electric vehicle drive motor

A pure electric vehicle and drive motor technology, applied in the direction of electric vehicles, motors, electric components, etc., can solve the problems of irregular space in the front cabin, many parts arranged, small space, etc., to solve the interference of components in the front cabin, The effect of reducing the radial size and reducing the axial space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

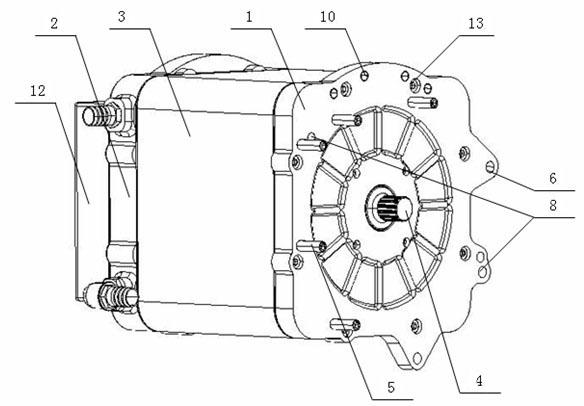

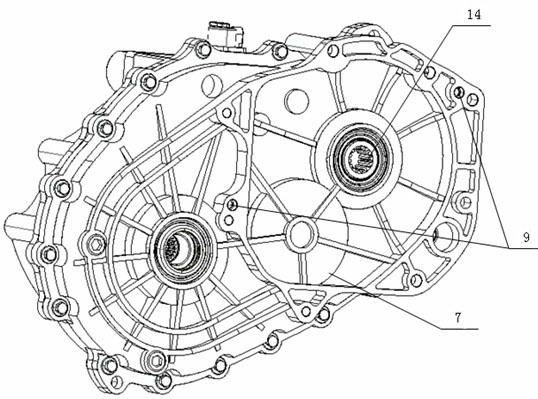

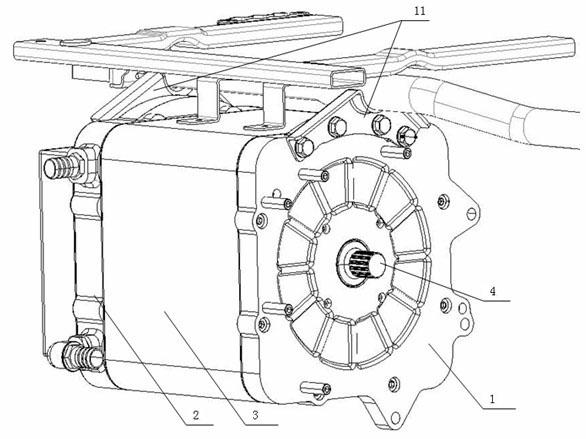

[0020] see figure 1 , The motor is mainly composed of a front end cover 1, a rear end cover (integrated with a junction box) 2, a motor body 3, and a rotor shaft 4. The front end cover 1 is an irregular shape, on the assembly surface with the reducer 7, with the motor shaft 4 as the center, five studs 5 connected to the flange surface of the reducer 7 are distributed on half of the side, and the other half A through hole 6 connected with the flange surface of the reducer 7 is provided on each of the three radially outwardly protruding parts, and connected to the flange surface of the reducer 7 . Two positioning pin holes 8 are additionally designed on the front end cover 1, and the positioning pins are used to cooperate with the positioning pin holes 9 on the flange surface of the reducer. The junction box 12 is installed on the rear end cover 2 of the motor. The fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com