Processing method of high-toughness Al-Si system die-casting aluminum alloy

A technology for casting aluminum alloys and processing methods, which is applied in the processing field of high-toughness Al-Si series die-casting aluminum alloys, can solve problems such as energy waste, cumbersome processes, and large phase volume fractions, and achieve improved mechanical properties, expanded application range, The effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

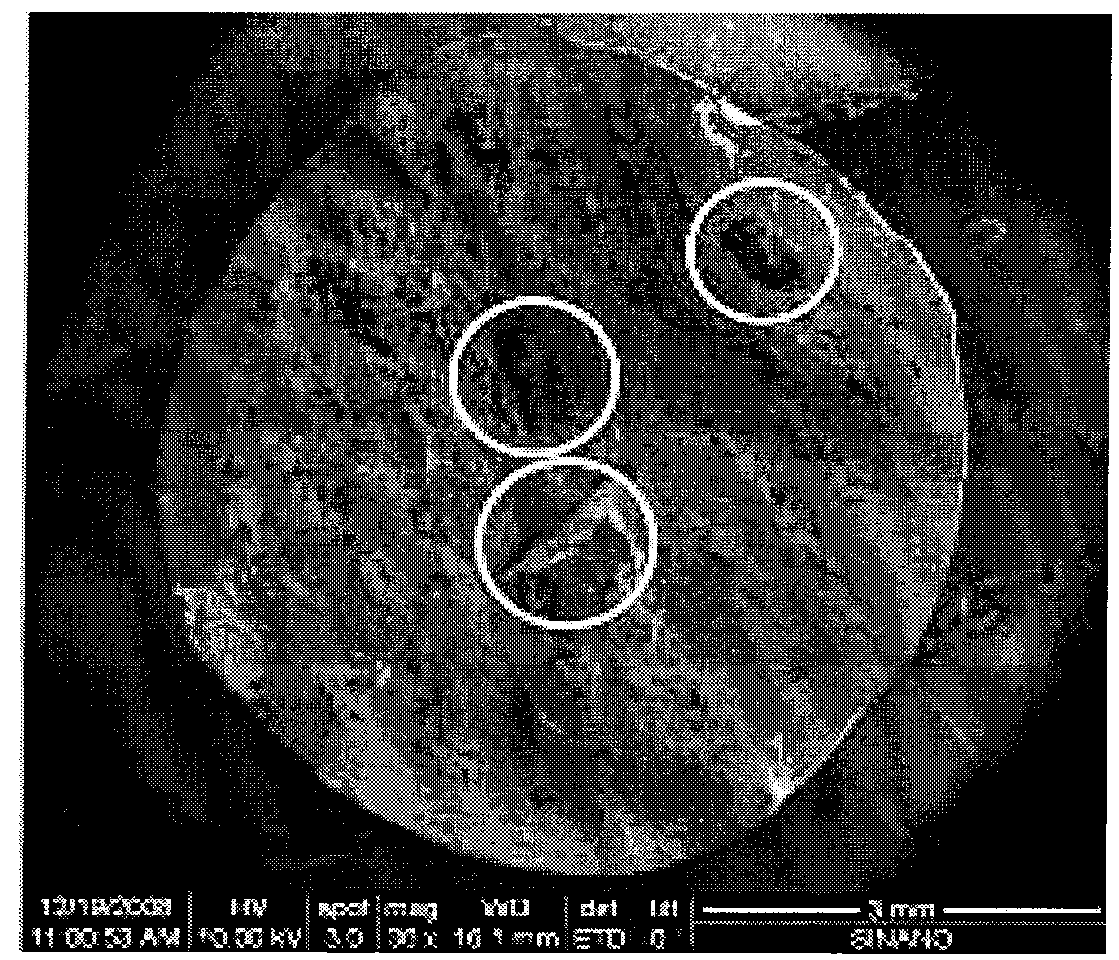

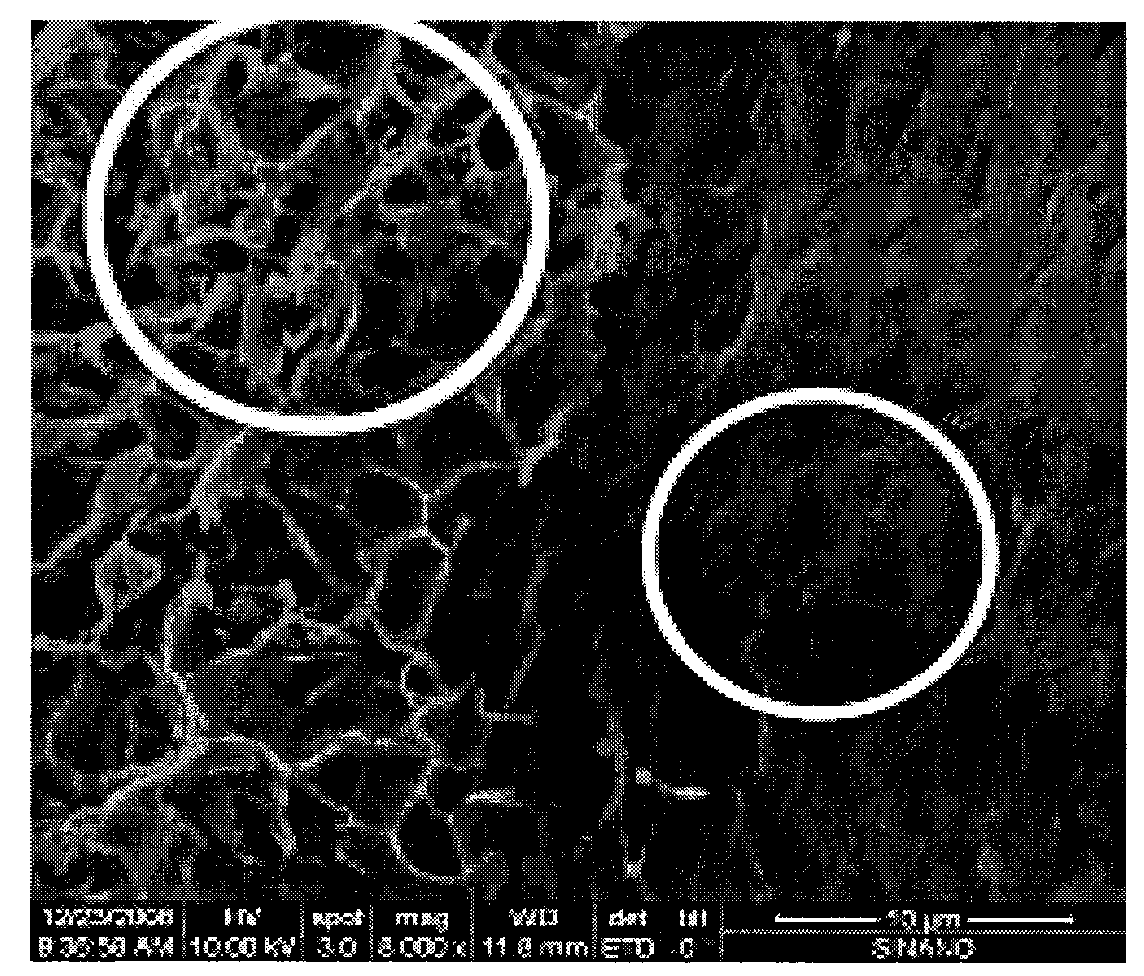

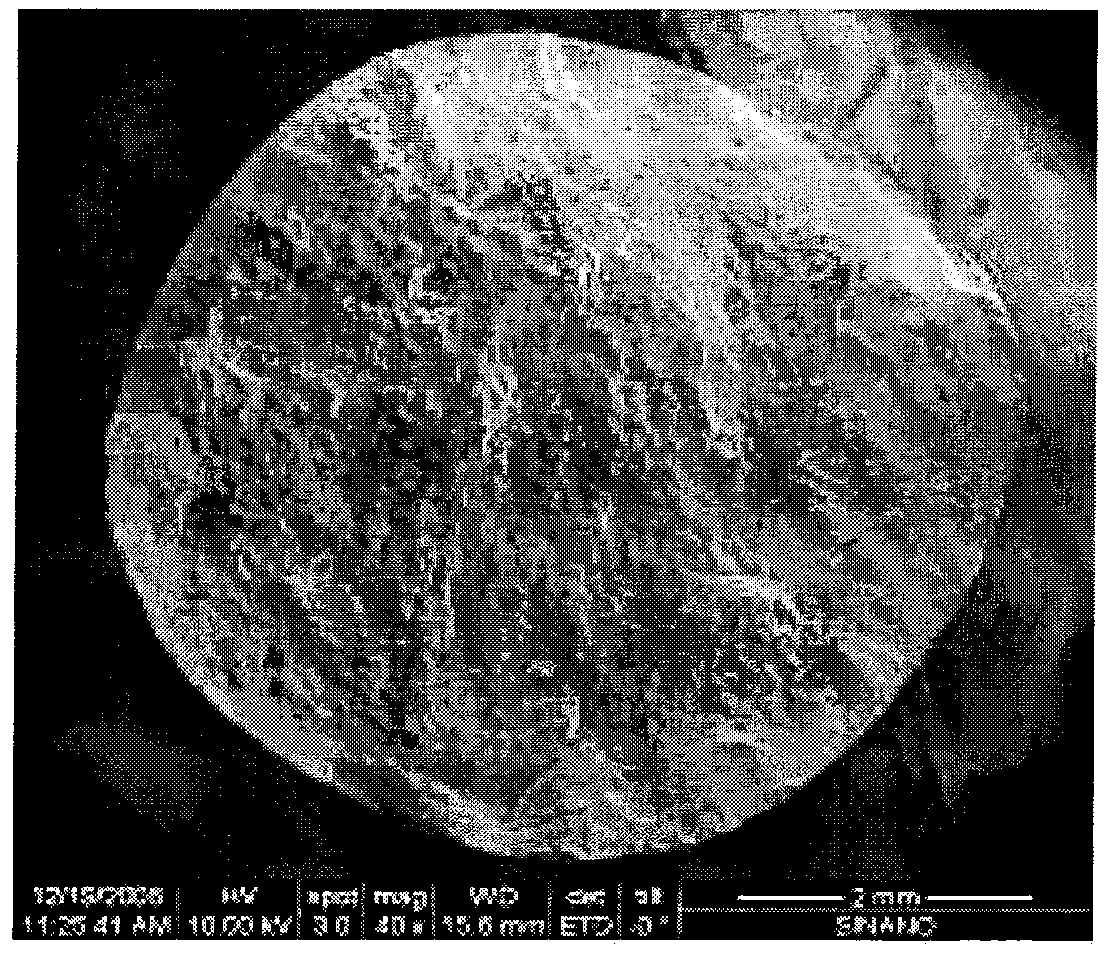

Image

Examples

preparation example Construction

[0028] The specific preparation process is as follows: firstly, according to the existing die-casting process, the fully treated aluminum alloy melt is die-casted at a certain temperature, the temperature of the die-casting mold is controlled at 350-400 ° C, and the holding time is 1-60 seconds. Then open the mold. After the mold is opened, quickly take it out and put it into the circulating cooling water for quenching. The transfer time is controlled to be less than 5 seconds. The quenching temperature is 350-550°C, the cooling water temperature is lower than 30°C, and the volume ratio of cooling water to workpiece is greater than 5. , removed from the circulating cooling water, and deburred. After deburring, anneal and hold at 50-250°C for 2-3 hours to eliminate the thermal stress generated during the quenching process and improve the toughness and fatigue strength of the workpiece.

[0029] Among them, it is preferable to control the temperature of the die-casting mold at ...

Embodiment 1

[0031] Taking ADC12 alloy die-cast washing machine 7kg triangular support as an example, the chemical composition of ADC12 alloy is Al-balance Si-10.8 Cu-2.5 Mg-0.3 Mn-0.5 Fe-0.9 Zn-1.0 Sn-0.2 Ni-0.5.

[0032] 1) Melting: using natural gas reverberatory furnace for melting, melting temperature is 650℃;

[0033] 2) Melt treatment: Purify, modify, and refine the melted ADC12 alloy melt, and then keep it warm at 630°C. The purification method is adsorption purification by blowing Ar gas, and the compound modifier is used for modification and refinement;

[0034] 3) Die-casting: remove the oxide layer on the surface of the melt-treated ADC12 alloy, and then add it to the die-casting machine. The temperature of the aluminum melt is 630°C, and the mold temperature is 380°C; clock mold;

[0035] 4) Quenching: Take out the workpiece quickly after opening the mold, put it into circulating cooling water with a water temperature lower than 30°C for quenching, the quenching temperature is ...

Embodiment 2

[0045] Taking AlSi12Cu alloy as an example, the chemical composition of the alloy is Al-remainder Si-11 Cu-1.2 Mg-0.4Mn-0.2 Fe-1.2 Zn-0.5 Sn-0.1 Ni-0.2.

[0046] 1) Melting: using natural gas reverberatory furnace for melting, melting temperature is 650℃;

[0047] 2) Melt treatment: Purify, modify, and refine the melted alloy melt, and then keep it warm at 630°C. The purification method is adsorption purification by blowing Ar gas, and the compound modifier is used for modification and refinement;

[0048] 3) Die-casting: After removing the surface oxide layer of the melt-treated alloy, add it to the die-casting machine. The temperature of the aluminum melt is 630°C, and the mold temperature is 350°C; ;

[0049] 4) Quenching: Take out the workpiece quickly after opening the mold, put it into circulating cooling water with a water temperature lower than 30°C for quenching, the quenching temperature is 350°C, and remove the burr of the workpiece after complete cooling;

[0050...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com