Wall building machine

A technology of wall building machine and mechanical arm, which is applied in the field of construction equipment, can solve the problems of difficult handling and stacking, large volume and weight, high construction cost, etc., and achieve the goal of solving the difficulty of building walls, high degree of automation, and saving time and cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is further described:

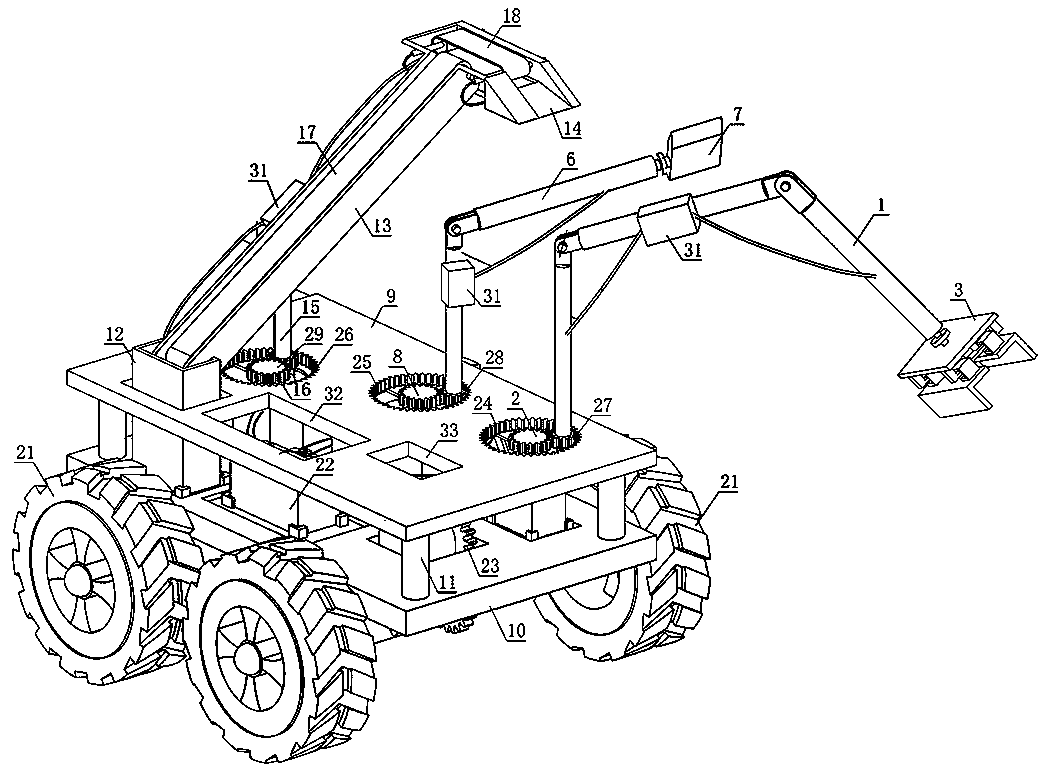

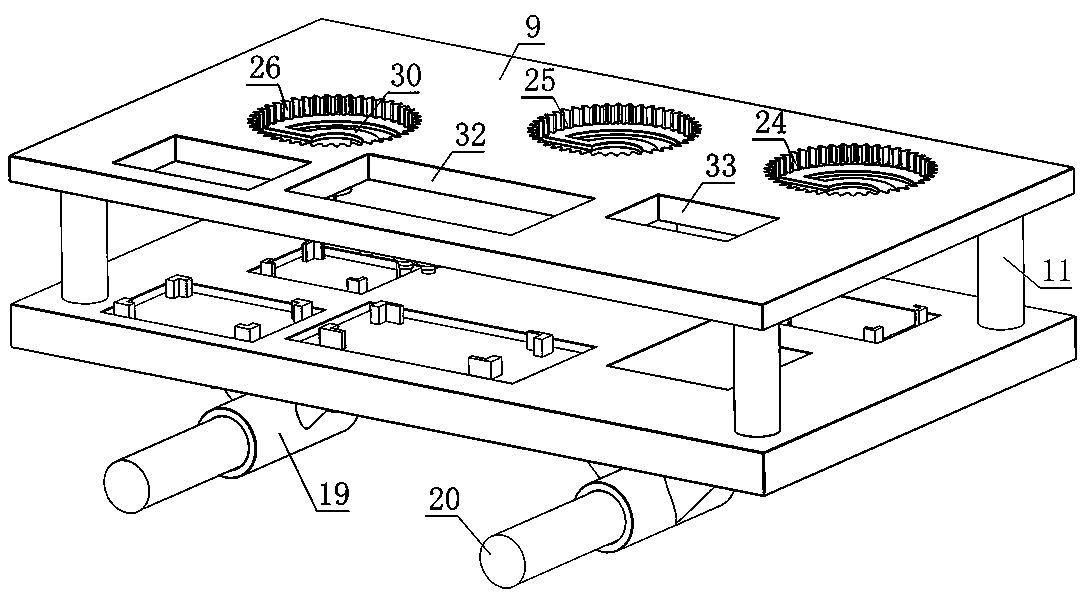

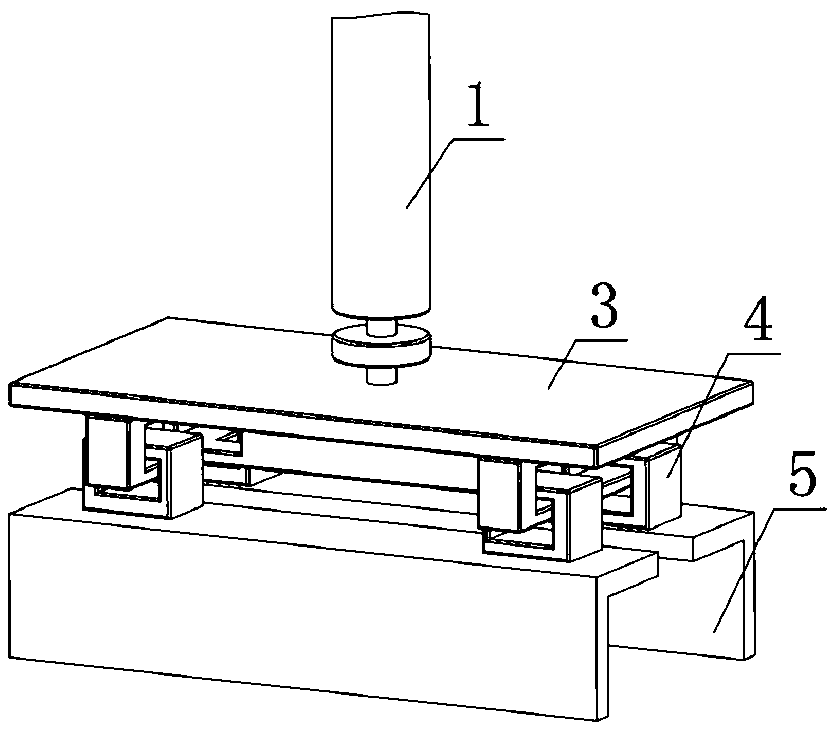

[0025] Such as Figure 1 ~ Figure 3 As shown, the wall building machine includes a brick grabbing mechanism, a slurry feeding mechanism and a plastering mechanism, and the brick grabbing mechanism, a slurry feeding mechanism and a plastering mechanism are all arranged on a working platform; the brick grabbing mechanism includes a first mechanical arm 1 and a brick clamping device, the brick clamping device is located at the top of the first mechanical arm 1, the end of the first mechanical arm 1 is connected to the working platform through the first gearbox 2, the brick clamping device includes a fixed plate 3, the Two groups of sliders 4 are arranged under the fixed plate 3, and claws 5 are respectively arranged under the sliders 4 of the two groups, and the claws 5 are inverted L-shaped; the plastering mechanism includes a second mechanical arm 6 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com