Porcelain brick conveying robot unit

A technology for manipulators and ceramic tiles, applied in the directions of manipulators, chucks, manufacturing tools, etc., can solve the problems of lack of practical auxiliary tools, high handling costs and poor safety for ceramic tile handling, and achieve safe and fast handling, convenient use and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

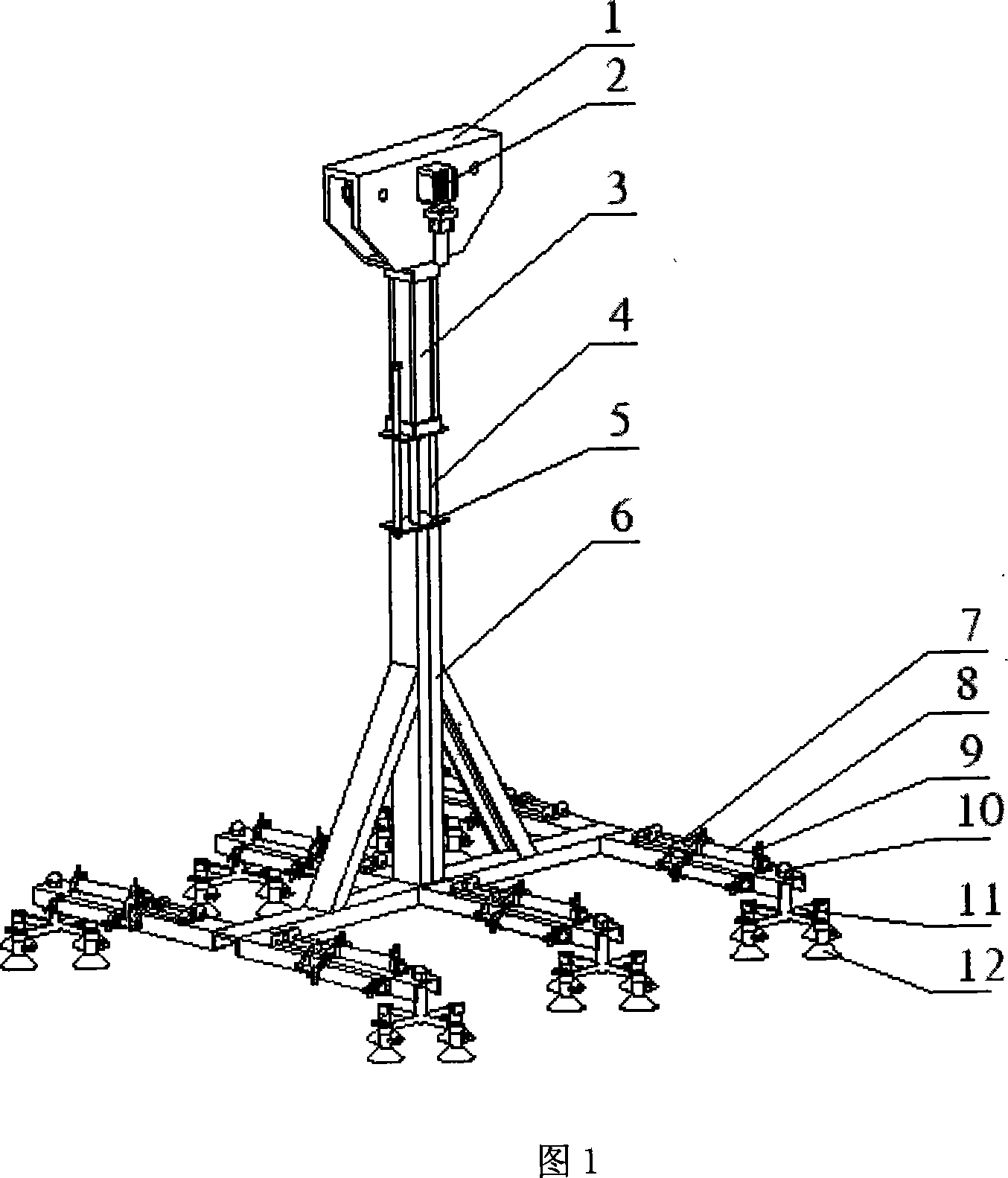

[0014] In Fig. 1, this tile handling manipulator device is composed of guide rail interface 1, motor 2, upper cylinder 3, connecting rod 4, cylinder joint 5, bracket 6, slide plate 7, bottom cylinder 8, adjustable joint 9, ball nut 10, cylinder connecting rod 11, suction cup 12 is formed. Four suction cups 12 are fixed together by cylinder connecting rods 11 to form a group, and are fixed on the bracket 6 by ball nuts 10. The bottoms of the three bottom cylinders 8 are fixed on the bracket 6 by hexagon socket screws, and the pistons are connected by slide plates 7. Together, the cylinder in the middle has gas input and output, and the piston can move back and forth, thereby driving the movement of the pistons on both sides. The cylinders on both sides are connected to the suction cups through a one-to-two joint. pressure, so that the tiles can be adsor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com