Simple carrying and discharging truck

A kind of unloading truck, simple technology, applied in the direction of lifting device, lifting frame, etc., can solve the problems of inflexible rotation angle, complicated control system, endangering personal safety, etc., and achieve the effect of reasonable design, ensuring personal safety and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

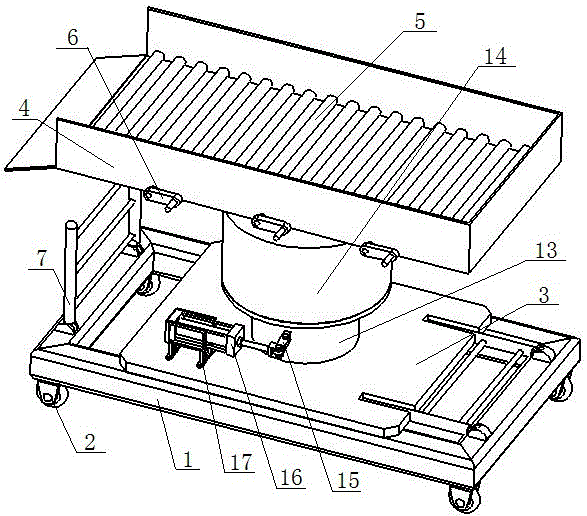

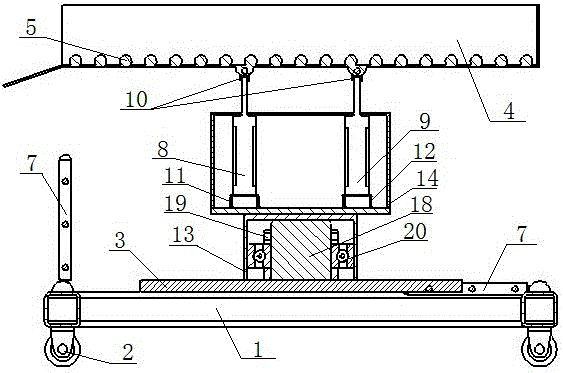

[0027] A simple handling and unloading vehicle of the present invention has a structure comprising a base 1, universal wheels 2, a support plate 3, and a material box 4; evenly arranged rollers 5 are installed above the inner bottom surface of the material box 4. The two ends of shaft 5 are movably installed on the two long side plates of the material box 4, and the center of the outer surface of the two ends of the roller shaft 5 is fixedly equipped with a rotary handle 6, and the two short side plates on the material box 4 are openable. The side panels that fit together; the support plate 3 is installed on the base 1, and foldable handrails 7 are symmetrically installed on both sides of the upper surface of the base 1; the universal wheels 2 are installed on the four corners of the base 1, and the universal wheels 2 are Self-locking universal wheels; the material box 4 and the support plate 3 are connected by a lifting mechanism and a rotating mechanism; the bottom of the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com