Fabrication method of microneedles based on inclined casting mold

A manufacturing method and microneedle technology, which is applied in the fields of medical cosmetic devices and microneedles for medical injection, can solve problems such as increasing process difficulty, reducing yield, and difficult installation, and achieves the effect of low process complexity and easy control of inclination angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

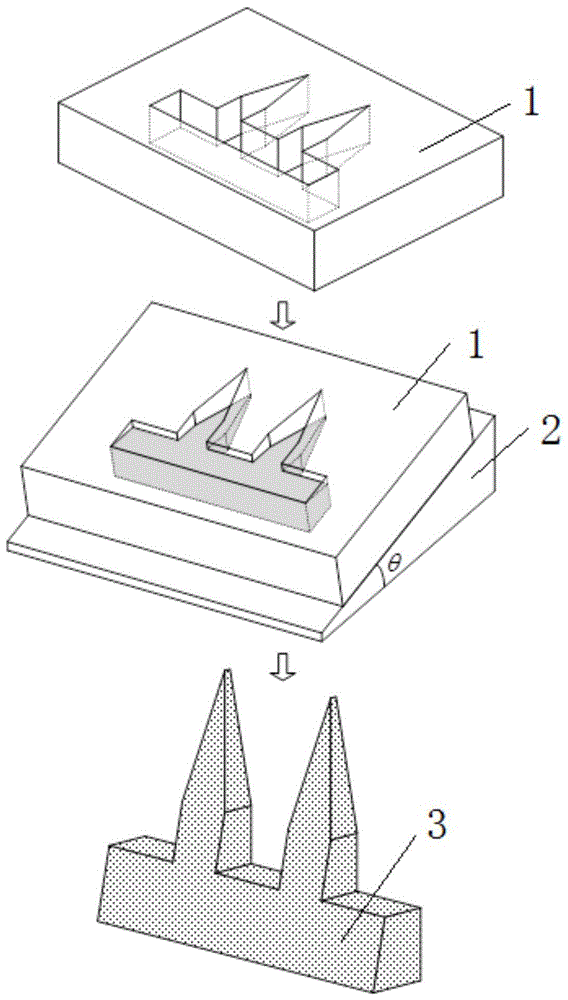

[0049] Example 1, such as image 3 Shown:

[0050] A method for manufacturing microneedles based on an inclined mold, comprising the following steps:

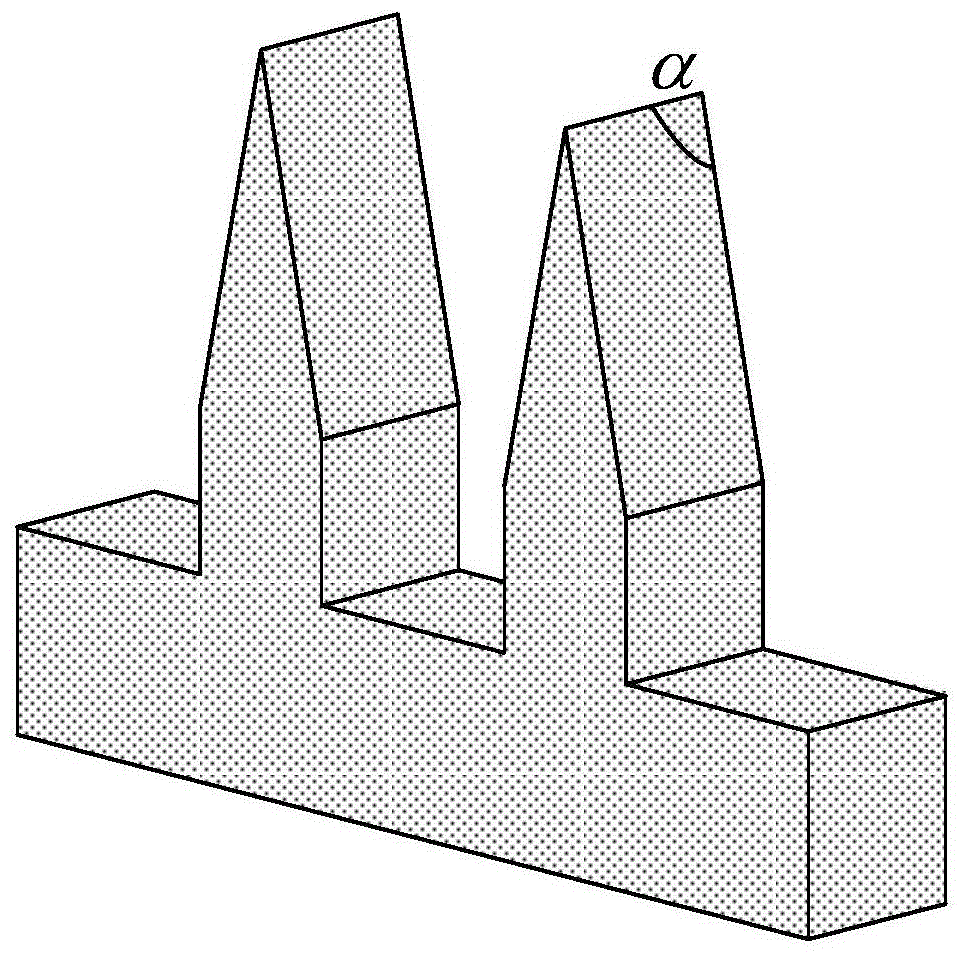

[0051] A) Use MEMS planar technology or laser ablation technology to make the same plane microneedle female mold 1, the material can be PDMS, the angle α between the needle tip is 90°, the thickness of the needle body is h, and the length of the needle body and the base is l;

[0052] Utilizing the MEMS plane process to make the same plane microneedle female mold 1 includes the following steps:

[0053] 1) Use AUTOCAD to draw a two-dimensional microneedle pattern and make a mask. The coplanar microneedle includes one or more needle bodies and a base connecting the needle bodies, and the needle body and the base are in the same plane. The length of the needle body is 300 μm, the width is 200 μm, the gap between the needle bodies is 500 μm, a single row contains 10 needle bodies, and the height of the base is 1 mm.

[0054] 2...

Embodiment 2

[0068] Example 2, such as Figure 4 Shown:

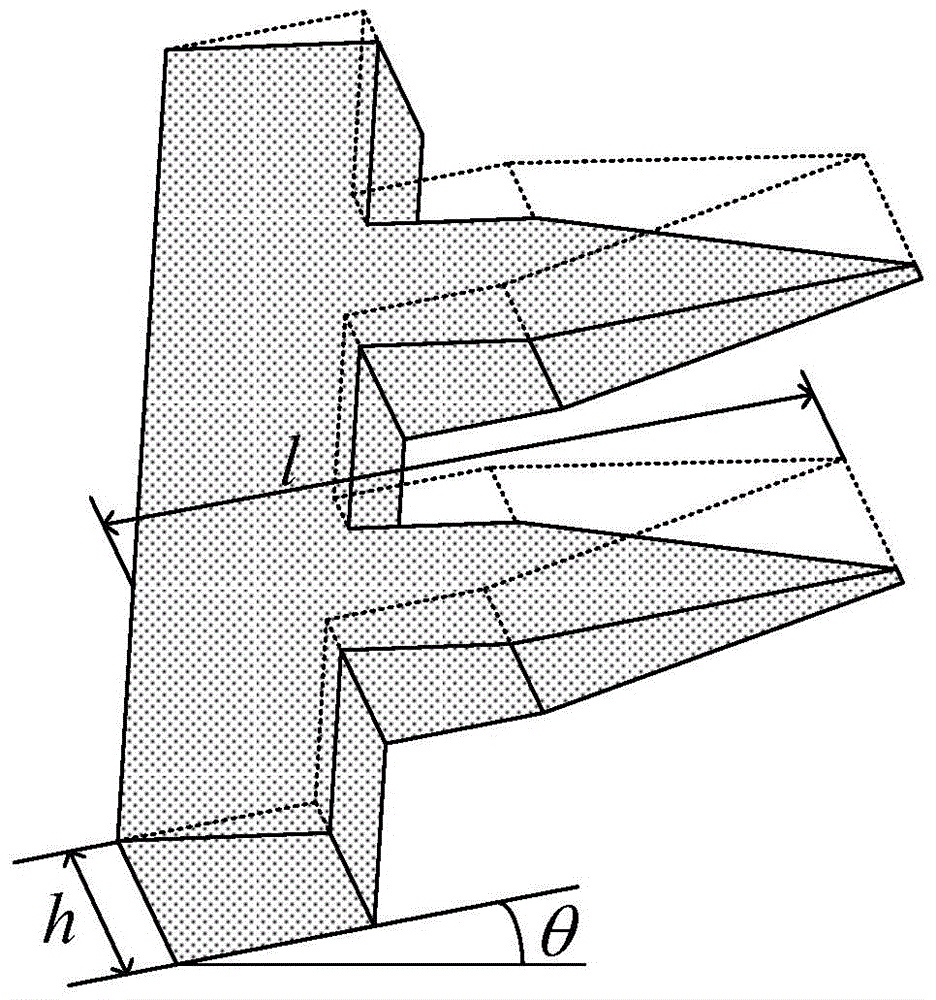

[0069] Another microneedle manufacturing method based on an inclined mold belonging to the same inventive idea has the following steps:

[0070] A) making the same plane microneedle female mold 1;

[0071] B) The coplanar microneedle female mold 1 is inclined by sticking the coplanar microneedle female mold 1 on the inclined surface of the inclined platform 2, and the axis of the needle body of the microneedle groove is perpendicular to the intersection of the inclined surface of the inclined platform 2 and the horizontal plane line, the tip of the microneedle groove of the same plane microneedle female mold 1 is at a low point, and the base of the microneedle groove is at a high point, that is, the needle body of the microneedle groove is facing downward;

[0072] C) pouring a liquid mold filling material into the microneedle groove of the coplanar microneedle female mold 1, and the coplanar microneedle female mold 4 with an inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com