Three-dimensional automatic feeding, discharging and detecting device

A technology of automatic loading and unloading, detection device, used in measuring/indicating equipment, metal processing machinery parts, metal processing and other directions, can solve the problems of high labor intensity, poor safety, low production efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] This embodiment is a three-coordinate automatic loading and unloading and testing device for processing and testing raw materials and workpieces with specific shapes, and is especially suitable for mass production and automatic processing requirements.

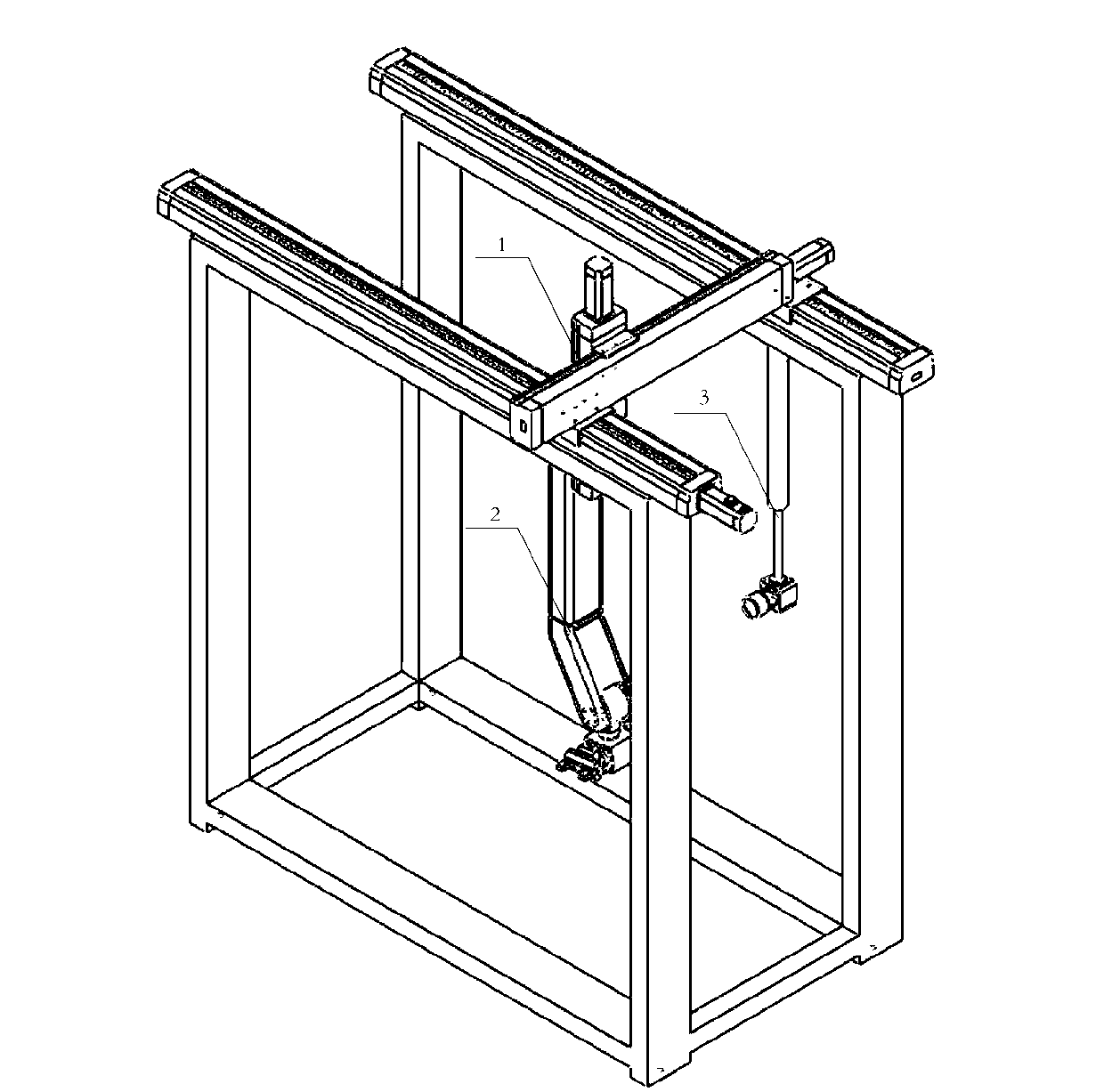

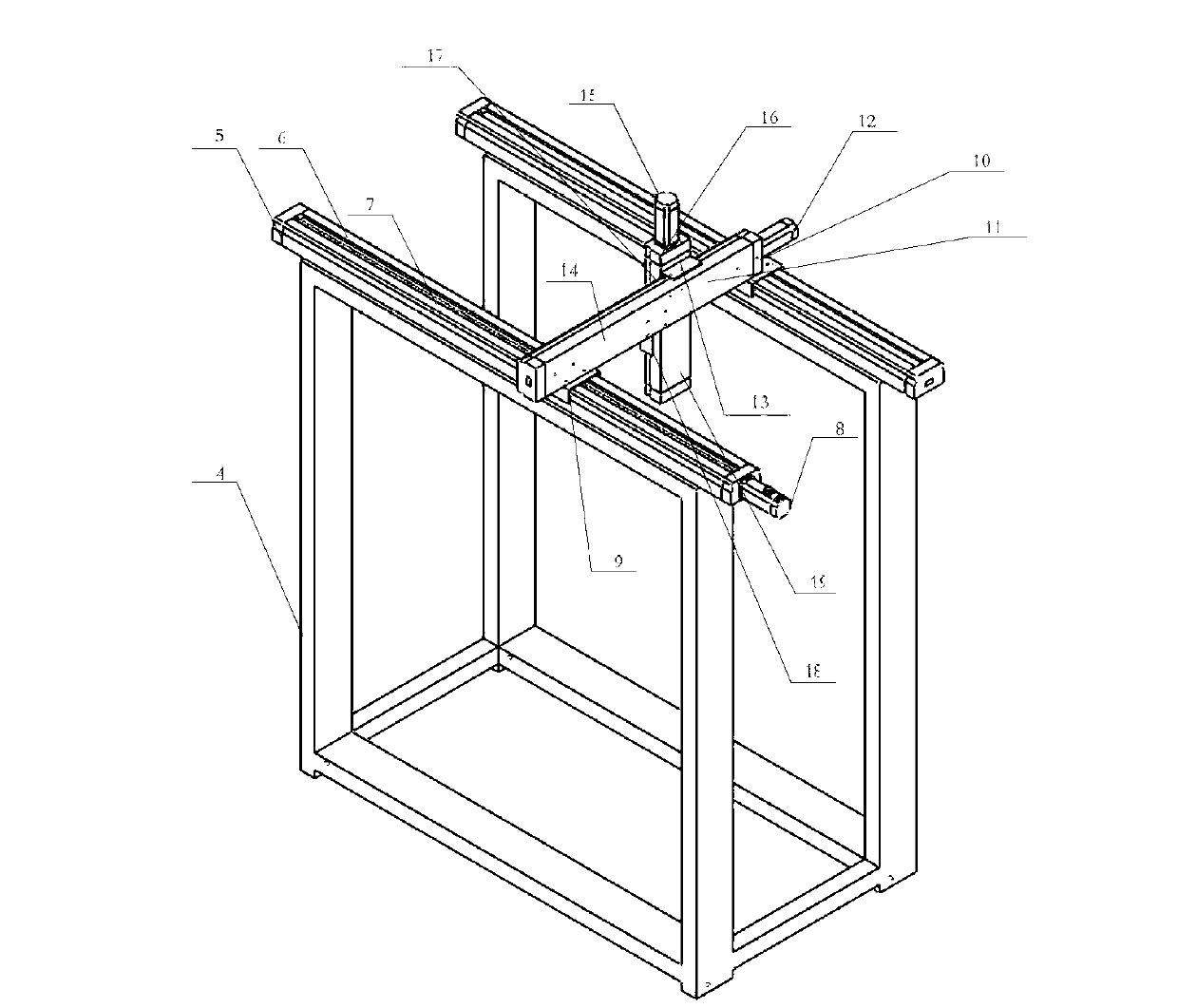

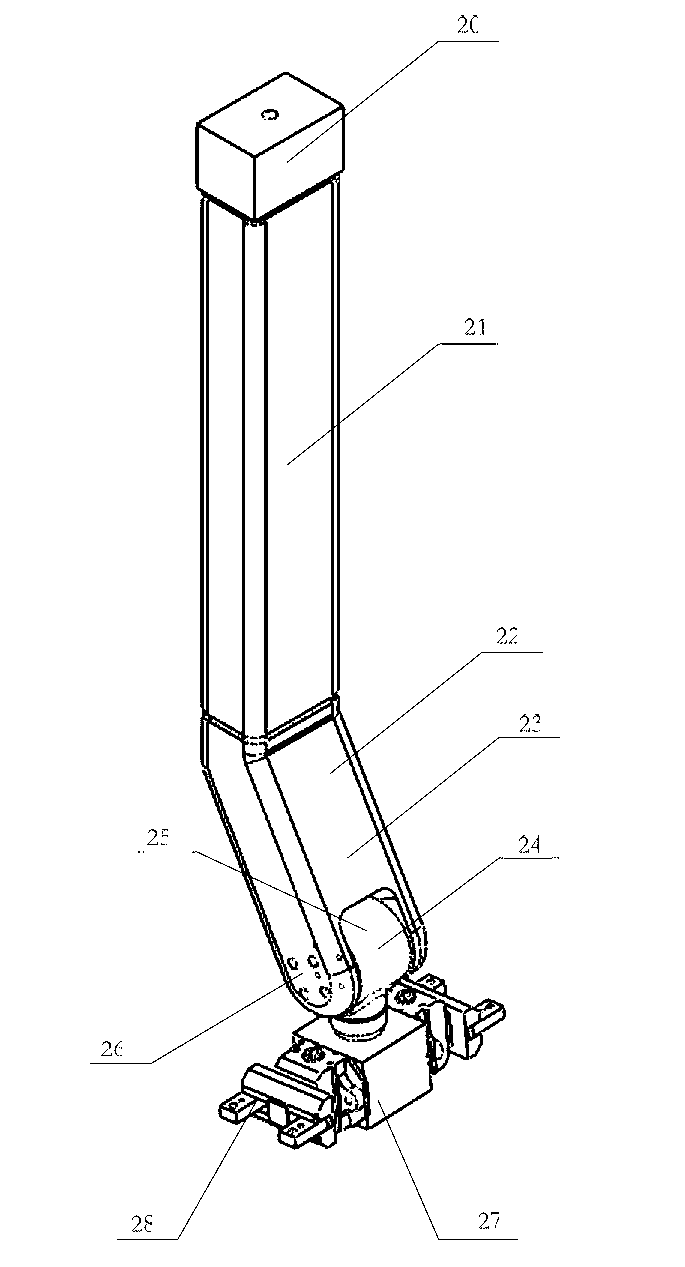

[0021] refer to figure 1 , figure 2 , the three-coordinate automatic loading and unloading and detection device of the present invention is composed of a three-dimensional motion mechanism 1, a manipulator actuator 2, an optical and visual automatic detection mechanism 3 and a bracket 4; the bracket 4 provides support for other components, and the three-dimensional motion mechanism 1 realizes X-axis, Y The movement in the three directions of axis and Z axis drives the actuator 2 of the manipulator to reach any designated position in the envelope space. The actuator 2 of the manipulator adjusts the snatch posture of the actuator through the rotation of the arm 23 and the manipulator 24. The automatic detection mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com