Front fork and rear rack transfer robot

A handling robot and rack-type technology, which is applied in the direction of lifting devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

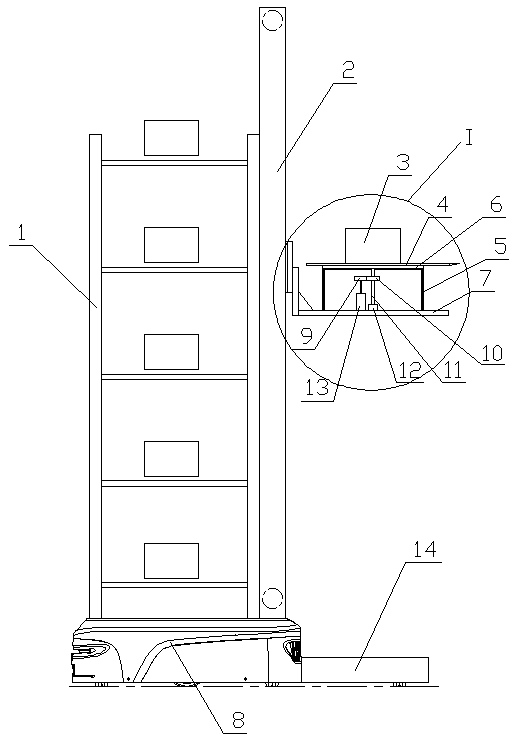

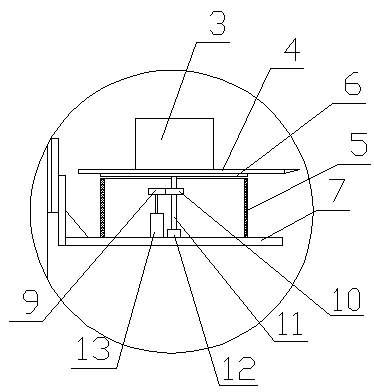

[0014] like figure 1 and figure 2 Shown, the front fork rear shelf type handling robot of the present invention contains self-propelled chassis 8. The self-propelled chassis 8 is provided with a lithium battery that can be independently charged online, a two-dimensional code plus a laser navigation mechanism, and a sensor. disabled function. The self-propelled chassis 7 has a self-weight of 450 kg, a total load of 300 kg, and a maximum running speed of 1.5 m / s.

[0015] A shelf 1 and a fork lifting mechanism 2 are fixed on the self-propelled chassis 8, and the self-propelled chassis, the shelf and the fork lifting mechanism are fixedly connected together. The shelf 1 has five layers, and can store five SKU commodity packing boxes 3 at a time. The fork lifting mechanism 2 is a traditional lifting mechanism, which is driven by a servo motor and driven by sprockets, chains and linear guide rails to achieve precise lifting of the forks. A flat plate 7 is connected to the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com