Compound circulating adjusting system of automatic guided vehicle (AVG) transfer carriage in automated logistics

A technology of transport trolley and adjustment system, applied in the field of dispatching system of AGV transport trolley, can solve the problems of waste of resources, low logistics efficiency, etc., and achieve the effect of improving logistics efficiency and reducing ineffective operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Now illustrate the present invention in conjunction with accompanying drawing and embodiment.

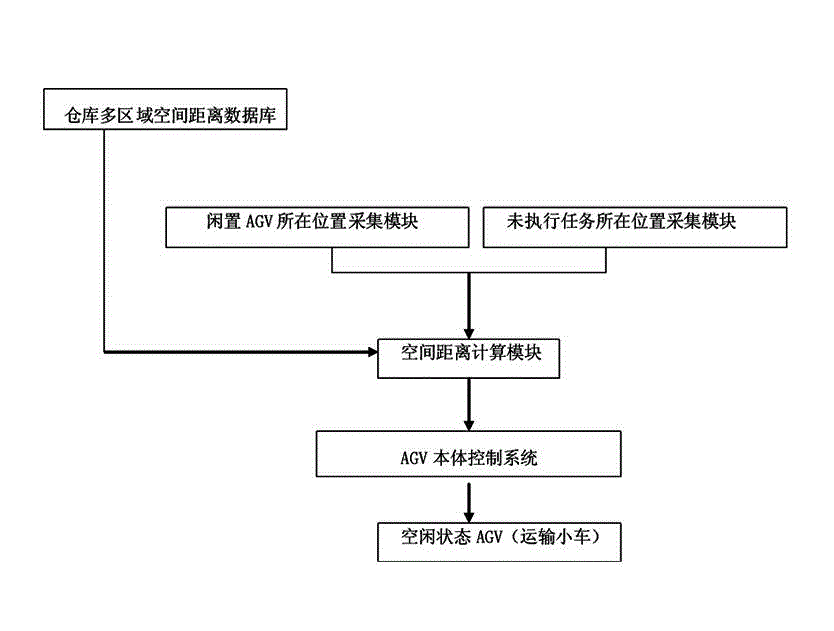

[0011] Such as figure 1 The compound cycle adjustment system of the AGV transport trolley in the automated logistics shown includes a computer scheduling system and an AGV body control system that controls the AGV transport trolley. The computer dispatching system includes a warehouse multi-area spatial distance database, an idle AGV position acquisition module, an unexecuted task position acquisition module, and also includes a spatial distance calculation module, which is connected to the idle AGV position The collection module, the location collection module of unexecuted tasks and the AGV body control system.

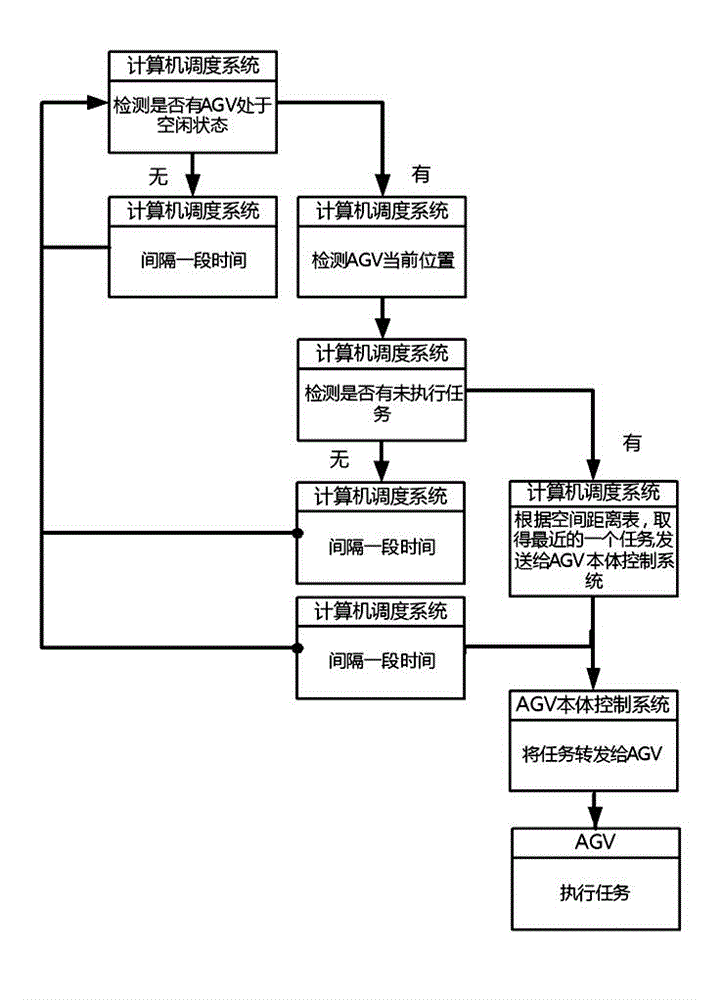

[0012] Such as figure 1 , 2 As shown, the warehouse multi-area spatial distance database: the entire warehouse is reasonably divided into multiple areas, and the traffic time between each area is manually measured and recorded in the spatial distance database. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com