Clamper

A clamper and clamping claw technology, applied in the high-throughput field, can solve the problems of reducing the operating positioning device of the experimental system, and the inability to integrate the feeding/subtracting system with the clamping system, so as to improve the experimental efficiency and reduce the Ineffective running process, reducing the effect of running positioning device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

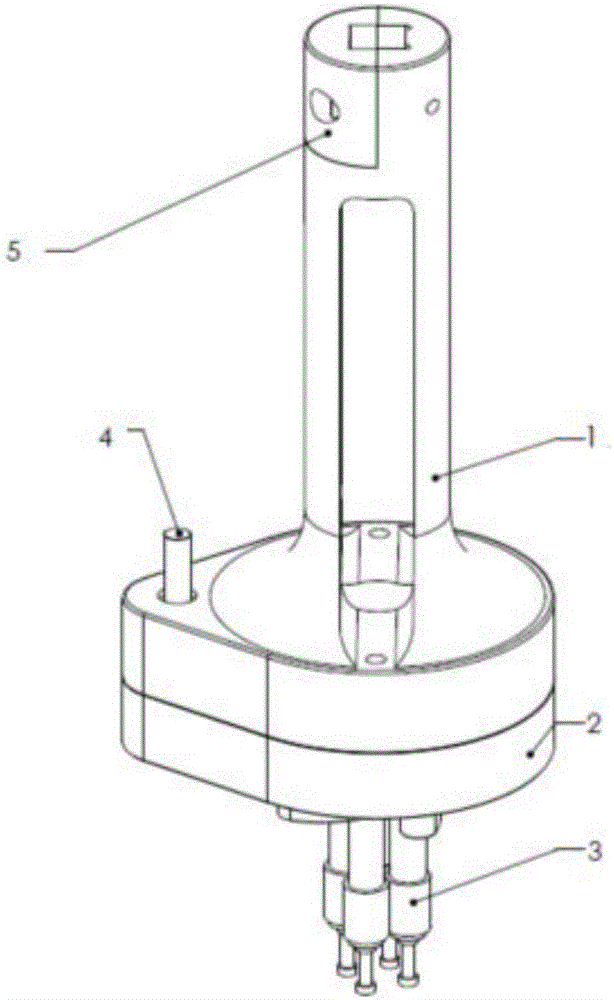

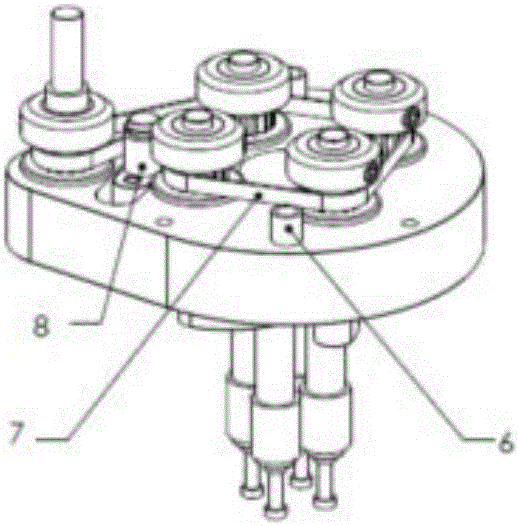

[0030] See below figure 1 , specifically introduces the structure of a clamper.

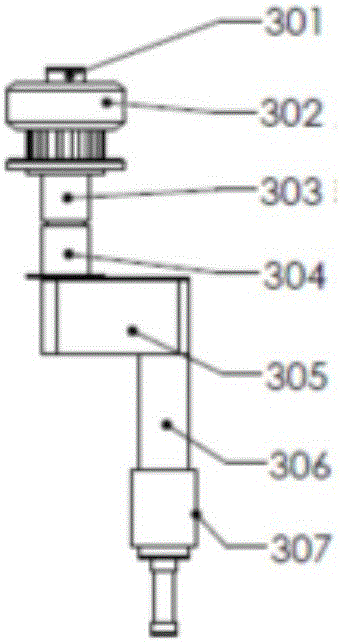

[0031] A clamper comprising an upper base 1 with a first through hole; a lower base 2 with a second through hole; clamping claws 3, the clamping claws 3 is arranged on the lower surface of the lower base 2; the drive shaft assembly 4, the drive shaft assembly 4 is connected with the clamping claw 3, and is used to drive the clamping claw 3 to move so as to clamp the work object; plus The material adding / subtracting channel 9 is located at the center of the holder and above the clamped workpiece, so that it is possible to add or subtract material to the workpiece during clamping.

[0032] Each element of the holder will be described in detail below.

[0033] First, introduce the upper base 1 and the lower base 2, see figure 1 as well as figure 2 . The upper base 1 and the lower base 2, the upper base 1 is provided with a first through hole, the lower base 2 is provided with a second through ...

Embodiment 2

[0038] In order to more clearly introduce the clamper provided by the embodiment of the present application, the embodiment of the present application also provides a method of using the clamper, as follows:

[0039] The use process of the holder is as follows: before use, the holder needs to be connected to the mechanical arm of the matching experimental equipment; through the connection between the pressing block 5 and the upper base 1 and the reserved interface on the mechanical arm, the clamping The holder is fixed on the mechanical arm of the experimental equipment. At the same time, the drive shaft assembly 4 is connected to the corresponding motor on the mechanical arm; The position of the container or object, the controllable motor controls the gripper to start running and grip the target reaction container or object, and then the gripper grips the target reaction container or object and moves to the target position with the mechanical arm; in the process The feeding / s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com