Automatic logistics system, method, and automatic logistics warehouse

A logistics system and automatic technology, applied in the direction of general control system, control/regulation system, comprehensive factory control, etc., can solve the problems of high logistics cost and long turnaround time, reduce manpower input, reduce overall cost, and low transshipment cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

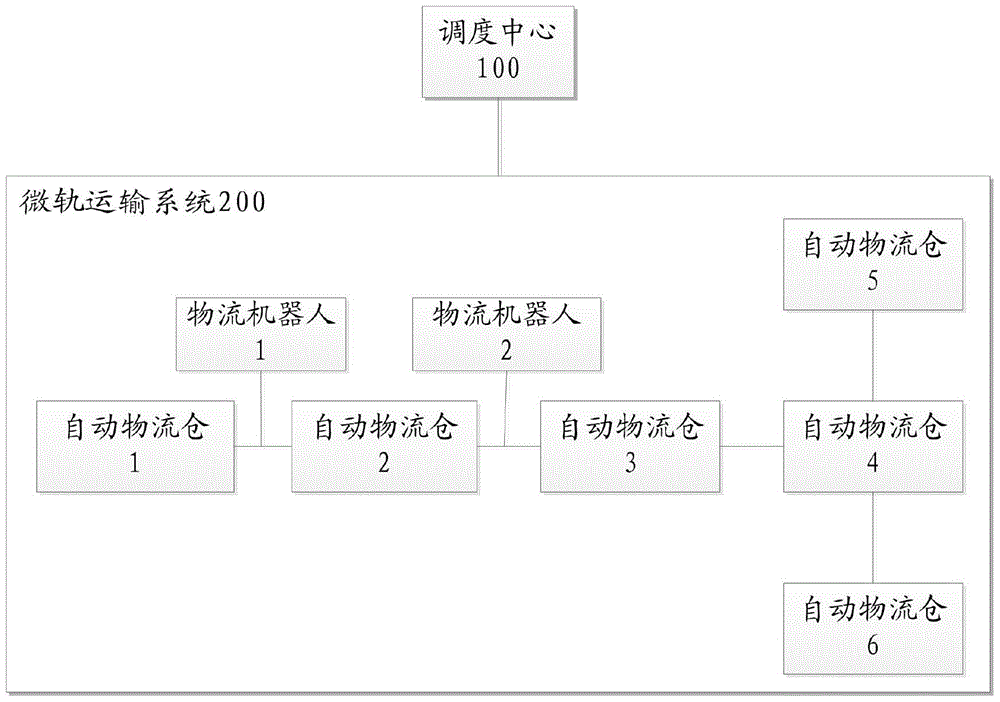

[0035] refer to figure 1 , Embodiment 1 of the present invention provides an automatic logistics system, including a dispatch center 100 and a micro-rail transportation system 200, the dispatch center 100 and the micro-rail transportation system 200 are connected through a wireless network, and the dispatch center 100 accepts 200 uploaded information, and issue orders or transfer information to the micro-rail transportation system 200.

[0036] Referenced figure 1 , the micro-track transportation system 200 includes at least one transportation track and several logistics robots, for example figure 1 The logistics robot 1 and the logistics robot 2 in the logistics robot; the logistics robot runs on the transport track; the automatic logistics warehouse for receiving or sending out express items is set along the transport track, for example figure 1 The automatic logistics warehouse 1, the automatic logistics warehouse 2, the automatic logistics warehouse 3, the automatic logi...

Embodiment 2

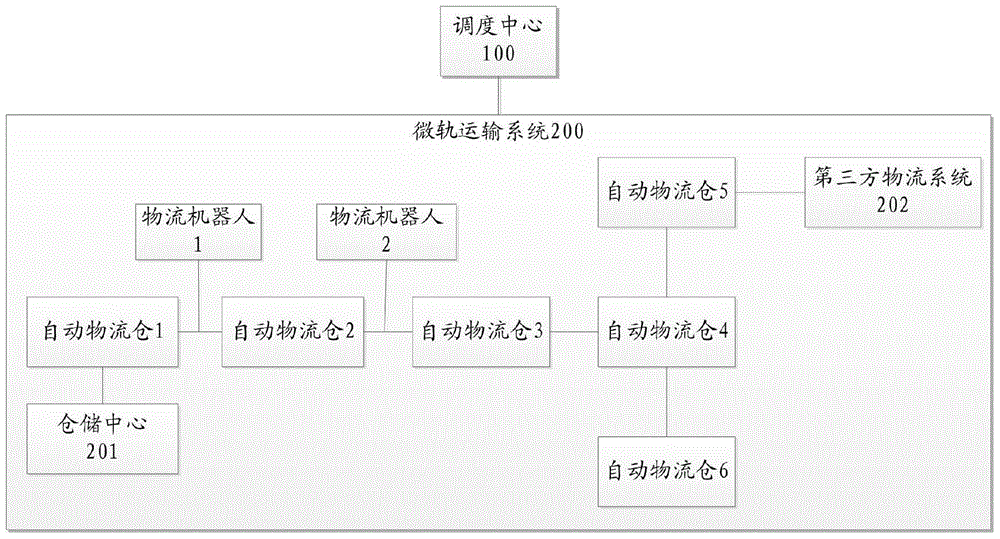

[0044] refer to figure 2 An automatic logistics system provided by Embodiment 2 of the present invention includes a dispatch center 100 and a micro-rail transportation system 200, the dispatch center 100 and the micro-rail transportation system 200 are connected through a wireless network, and the dispatch center 100 accepts micro-rail transportation The system 200 uploads the information, and issues scheduling commands to the logistics robots and automatic logistics warehouses of the micro-rail transportation system 200.

[0045] refer to figure 2 , the micro-track transportation system 200 includes at least one transportation track and several logistics robots, for example figure 2 The logistics robot 1 and the logistics robot 2 in the logistics robot; the logistics robot runs on the transport track; the automatic logistics warehouse for receiving or sending out express items is set along the transport track, refer to figure 1 , the micro-track transportation system 200...

Embodiment 3

[0052] refer to Figure 4 , Embodiment 3 of the present invention provides an automatic logistics method, comprising the following steps:

[0053] S101, the automatic logistics warehouse receives the express item and the logistics information corresponding to the express item;

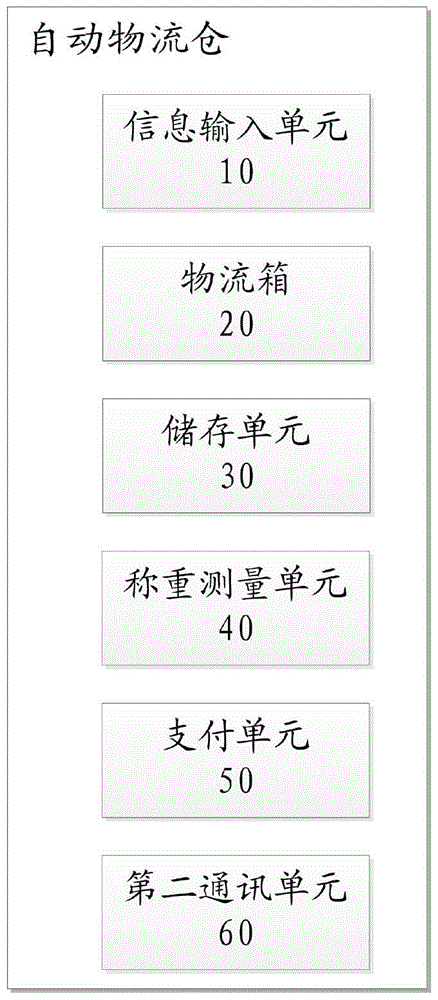

[0054] Specifically, the automatic logistics warehouse is an automatic logistics warehouse, and the automatic logistics warehouse is set as figure 2 The structure shown, the information input unit 10, the logistics box 20, the storage unit 30, the weighing measurement unit 40, the payment unit 50, the second communication unit 60; the information input unit 10 accepts the input logistics information; the logistics box 20 is used to receive express delivery; the storage unit 30 is used to store logistics boxes containing express items, and the logistics box 20 is transported to the storage unit 30 by crawlers or transfer trolleys. The second communication unit 60 is used to send information to the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com