Noise reduction vibration isolator for subway

A vibration isolator and noise reduction technology, applied in roads, buildings, tracks, etc., can solve problems such as affecting the use effect and vibration isolation effect of rubber vibration isolators, low lateral stiffness and weak lateral support force of rubber vibration isolators, etc. Achieve the effect of improving the lateral support force, ensuring the vibration isolation effect, and improving the vibration isolation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

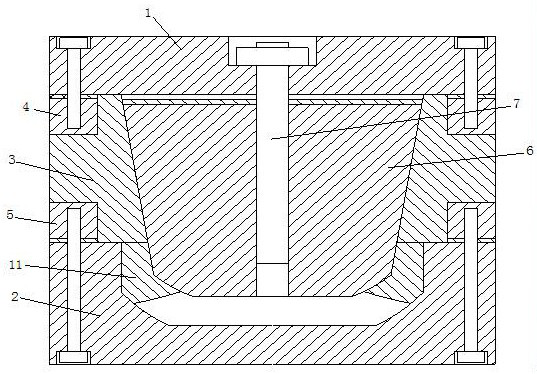

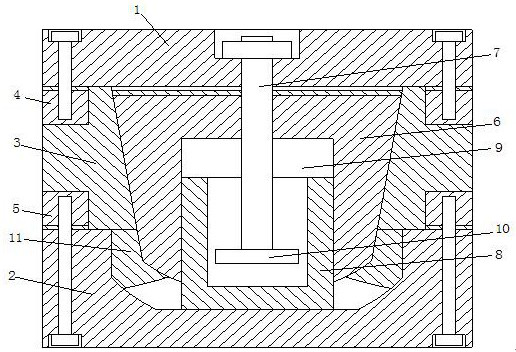

[0040] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the lower fixing part includes a lower cylinder 8, the lower cylinder 8 is fixedly arranged on the lower bottom plate 2, and the lower cylinder 8 is arranged toward one end of the upper supporting plate 1 There is an opening, and the upper plug-in column 6 is provided with a sliding groove 9 cooperating with the lower cylinder body 8, and the lower cylinder body 8 is inserted into the sliding groove 9 and is slidably connected with the sliding groove 9; the connecting guide rod 7 passes through The upper insertion post 6 and its end are arranged in the lower cylinder 8, and one end of the connecting guide rod 7 arranged in the lower cylinder 8 is threadedly connected with a pressure plate 10, and the lower cylinder 8 is filled with damping viscous fluid.

[0041] In this application, when the upper support plate 1 vibrates and moves, the pressure bearing piece 10 connecting the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com