Vibration isolation hub for fans

A fan and vibration isolation technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of blade body retention, rotational instability, vibration reduction, etc., achieve deformation suppression, reduce radial size, improve The effect of productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

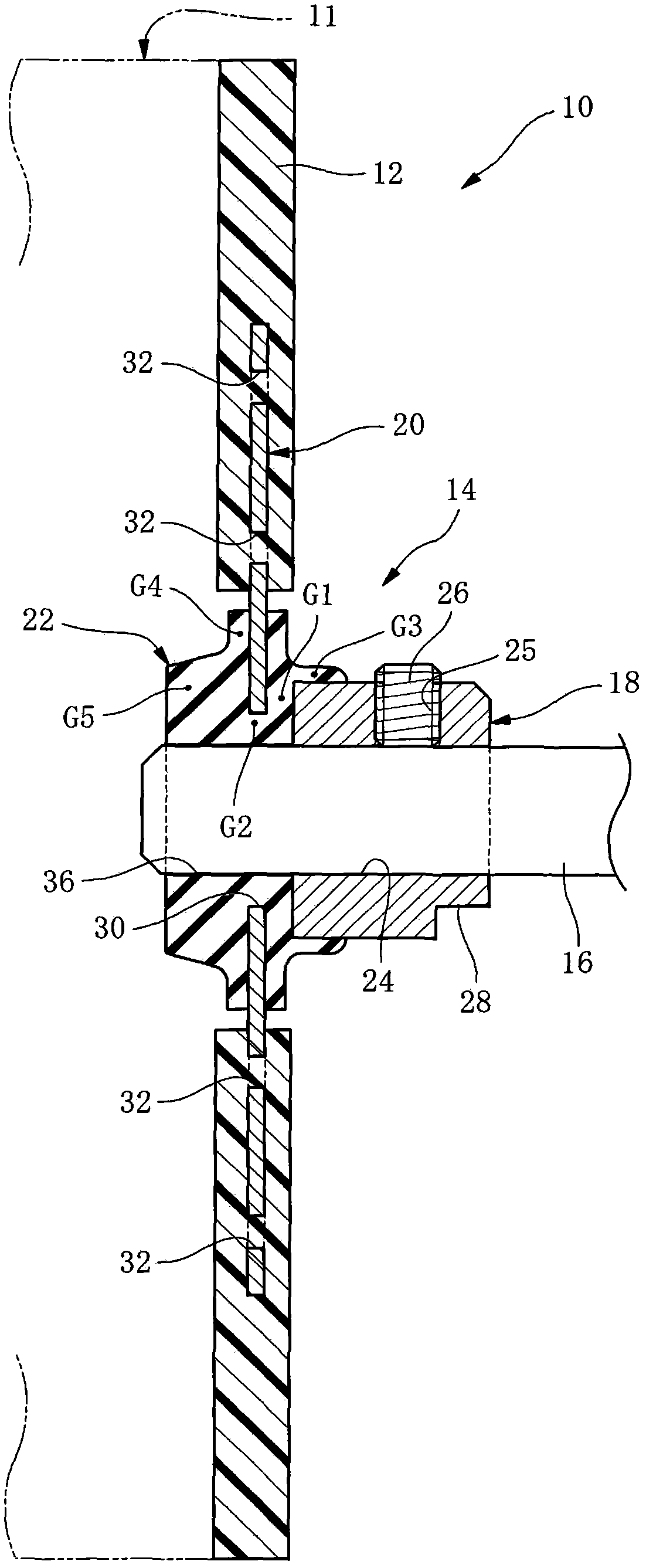

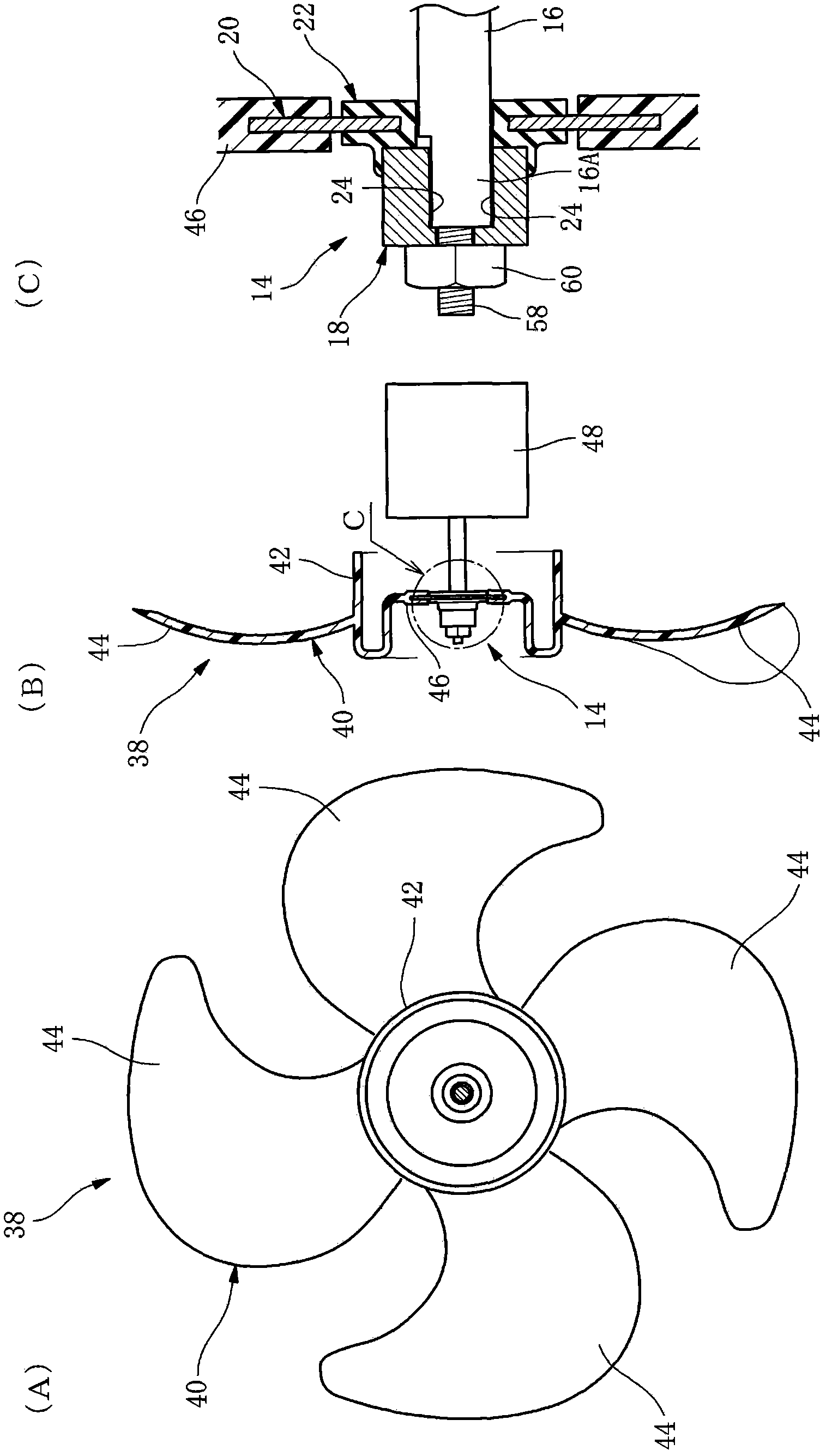

[0062] Next, embodiments of the present invention will be described in detail below based on the drawings.

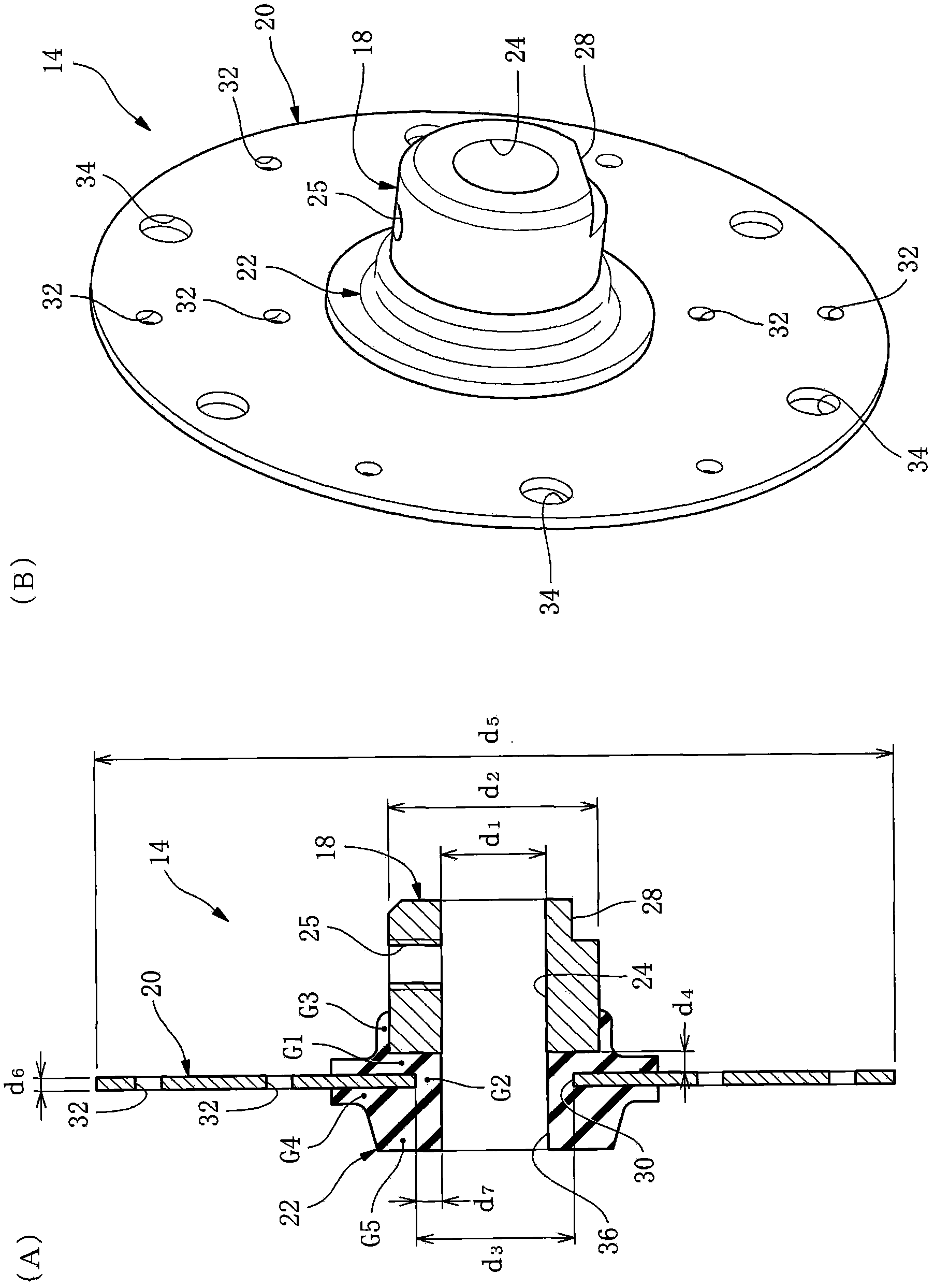

[0063] exist figure 1 Among them, reference numeral 10 is a cross-flow fan, reference numeral 12 is an end plate of the blade body 11 of the cross-flow fan 10, and reference numeral 14 is the central part of the blade main body 11, and is provided at the central part of the end plate 12 in detail. The isolation hub, 16 is the rotating shaft protruding from the motor side.

[0064] The vibration isolation hub 14 has an inner cylinder member 18 as an inner member, a disc-shaped connection plate 20 as an outer member, and a joint elastically connecting the inner cylinder member 18 and the connection plate 20 to the inner cylinder member 18 and the connection plate 20 integrally. The elastic body 22 of the plate 20 .

[0065] Here, both the inner cylinder member 18 and the connecting plate 20 are rigid members made of metal. However, the inner cylinder member 18 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com