Emptying magazine and method for emptying trays filled with rod-like articles in the tobacco-processing industry

A technology of shaped products and processing industry, applied in the field of emptying material boxes and methods for emptying material boxes filled with rod-shaped products of tobacco processing industry, capable of solving efficiency loss, high cost, high labor intensity of spring replacement, etc. problem, to achieve the effect of flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

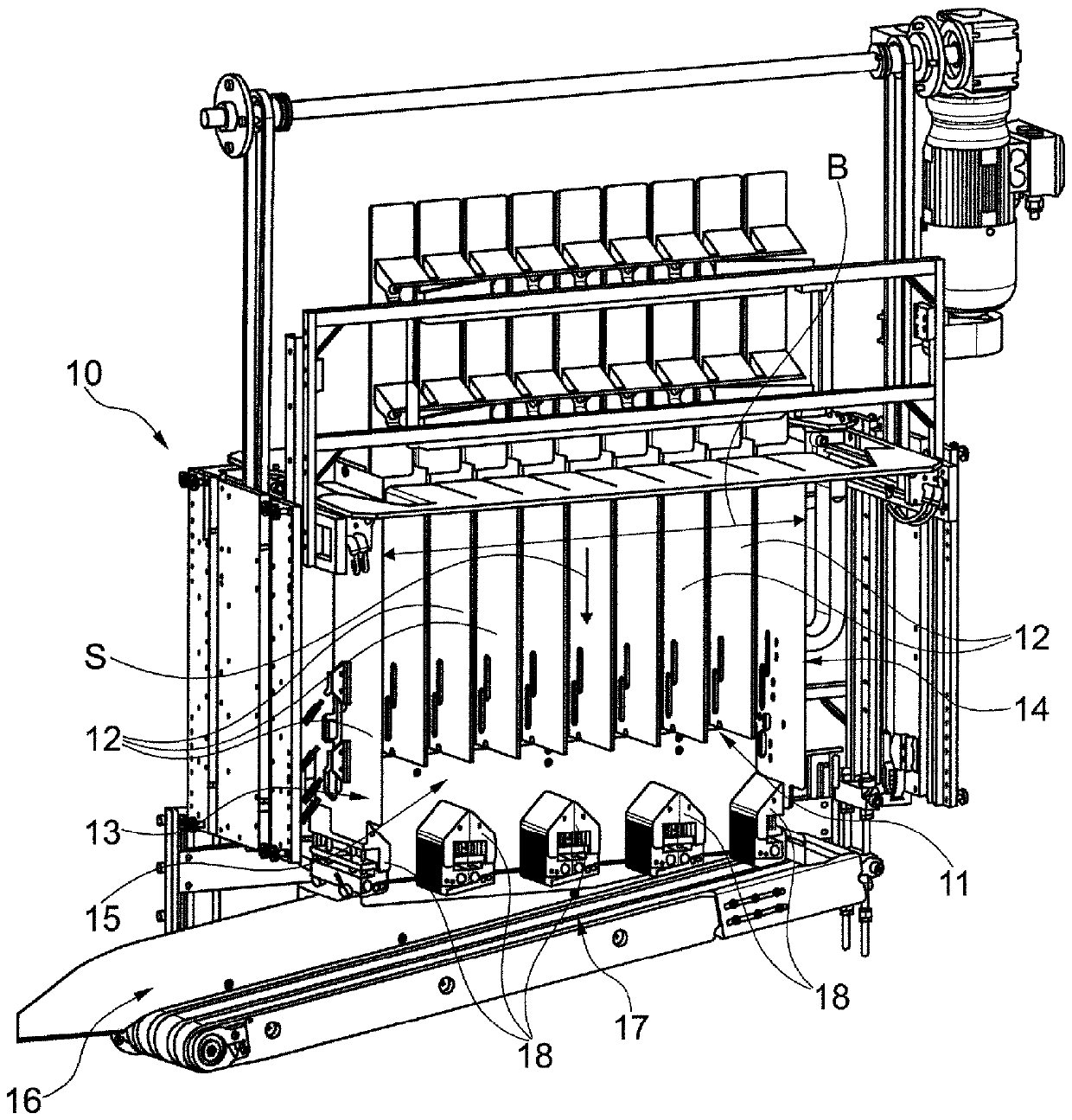

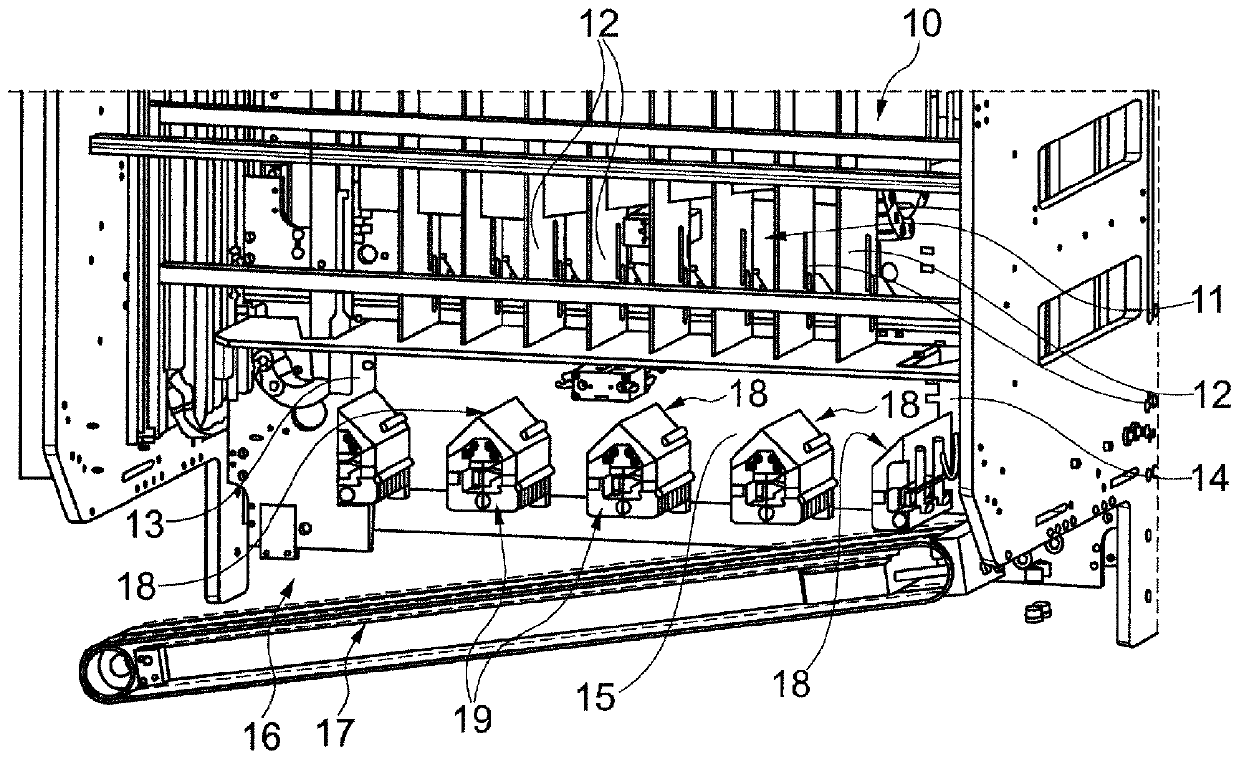

[0024]The emptying cartridge shown in the drawing is used for emptying shaft trays filled with rod-shaped products from the tobacco industry. Of course, the emptying magazine according to the invention is also designed and designed for emptying trays and other containers in which rod-shaped products are stored.

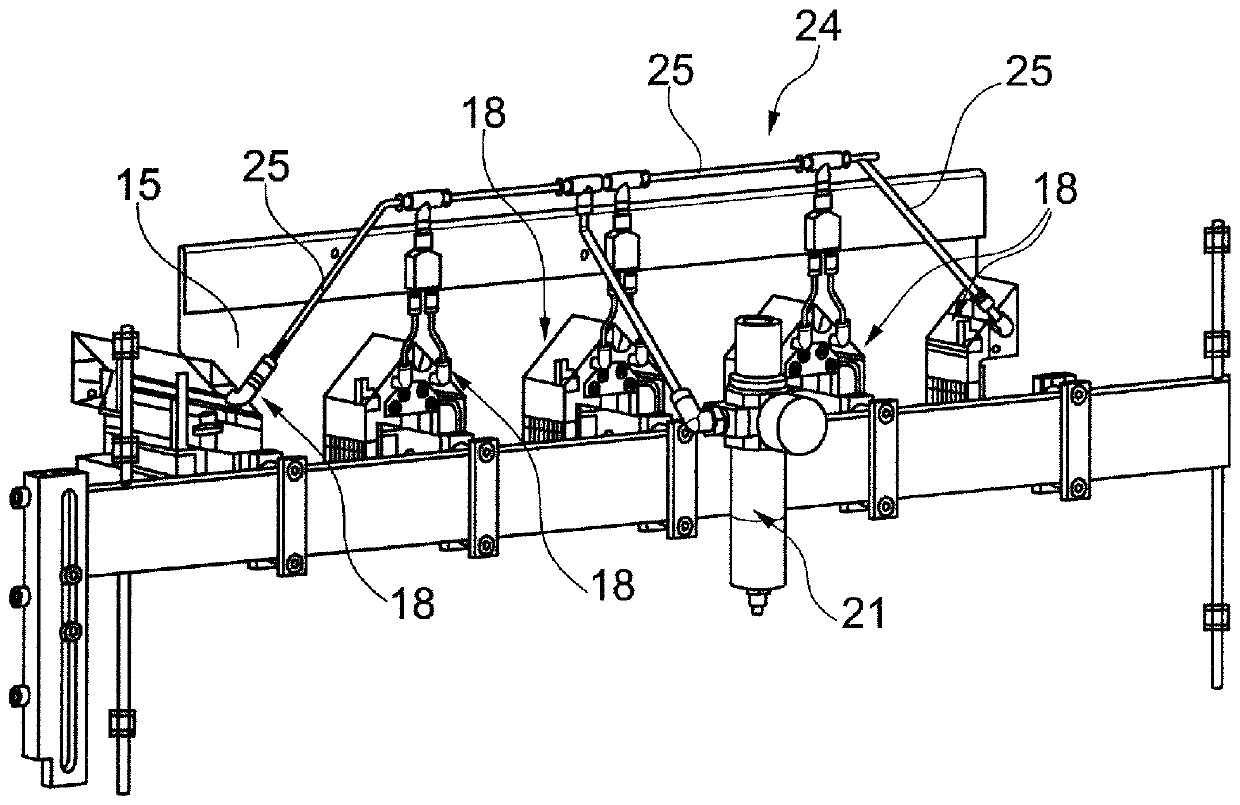

[0025] exist figure 1 shows an emptying magazine 10 for a tray emptying station for emptying trays filled with rod-shaped products from the tobacco processing industry. The emptying magazine 10 comprises an accommodating chamber 11 , which in the exemplary embodiment is divided into a plurality of wells by a separating element 12 , but can also be provided without a separating element 12 . The press chamber 11 is used to receive the products flowing from the tray. The receiving chamber 11 is delimited at least on the sides 13 , 14 and the rear 15 and is open upwards in the direction of the tray to be emptied and delimited downwards by a conveying element 17 forming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com