Bionic hair sensor for flow velocity, acceleration and angular velocity sensitivity

A bionic hair and acceleration technology, applied in the direction of velocity/acceleration/shock measurement, acceleration measurement using gyroscope, fluid velocity measurement, etc., can solve the problems of single function, poor practicability, complex structure, etc. Effects of thermal stress and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

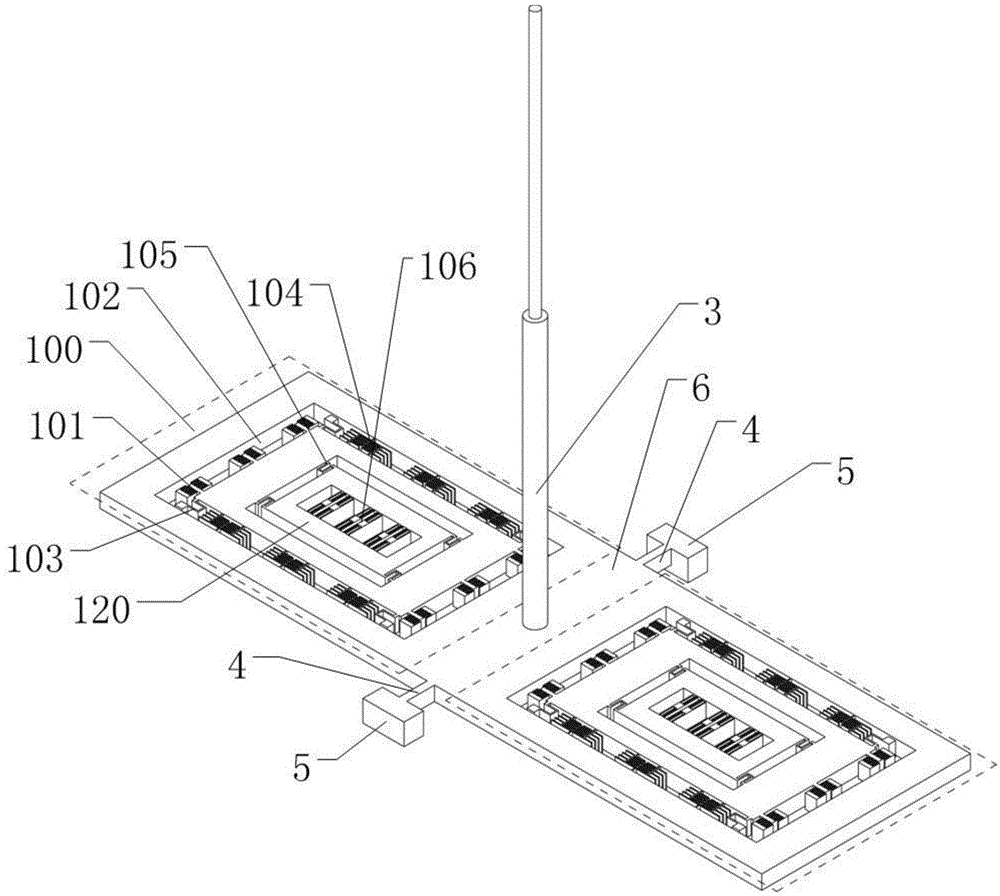

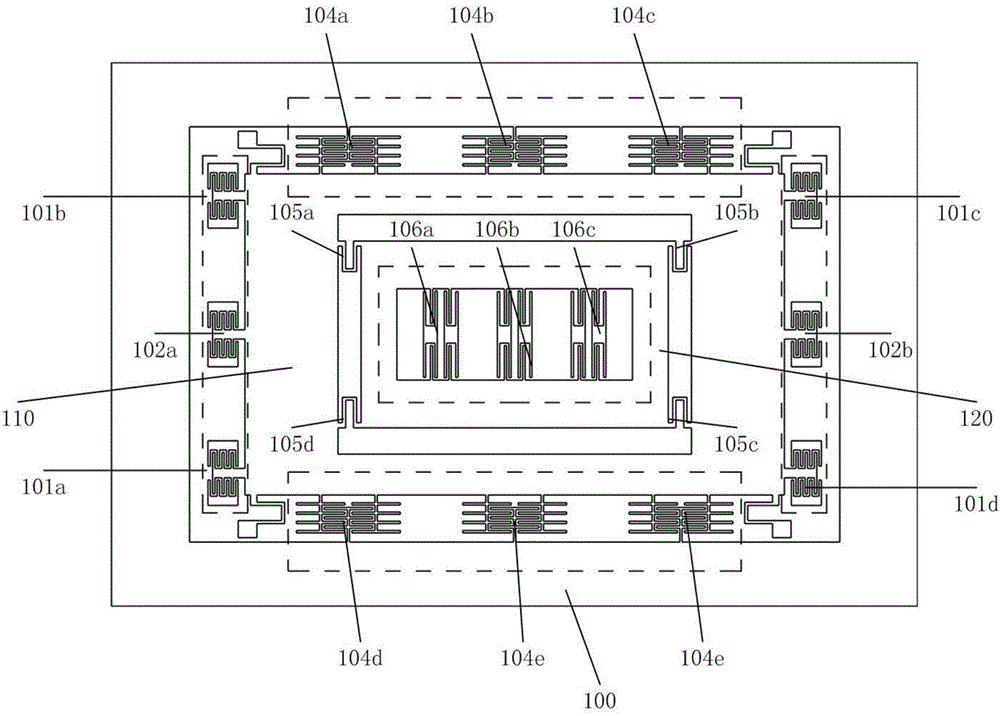

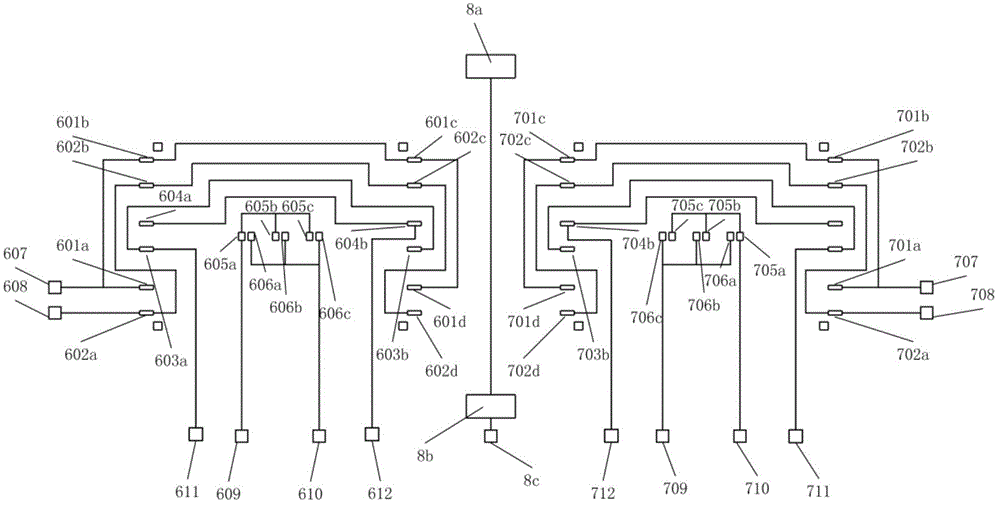

[0038] Such as figure 1 As shown, the bionic hair sensor sensitive to flow velocity, acceleration and angular velocity of the present invention is composed of upper, middle and lower layers, the upper layer is polymer hair, the middle layer is a silicon microsensor structure, and the lower layer is a signal lead made on a glass substrate . Used to measure the flow velocity and acceleration along the X-axis direction in the same plane, and the angular velocity input in the Z-axis direction, the silicon microsensor structure consists of an outer frame 6, two sets of symmetrical middle frames 110 and two sets of symmetrical inner frames 120 compositions. The external frame is connected with anchor points 5 fixed on the glass substrate through torsion beams 4 . Two identical middle frames 110 are symmetrically arranged inside the outer frame 5, and are connected to anchor points fixed on the glass substrate through U-shaped elastic beams 103, so that the middle frames are suspen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com