Integrated full-color 3D printing equipment and method

A 3D printing and 3D printer technology, which is applied in the field of integrated full-color 3D printing methods and equipment, can solve the problems of uneven mixing of different color consumables, reduced connection strength of color changing interface, and inability to achieve continuous printing, etc., to improve printing accuracy. degree and product apparent quality, improve the effect of use occasions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with specific illustrations.

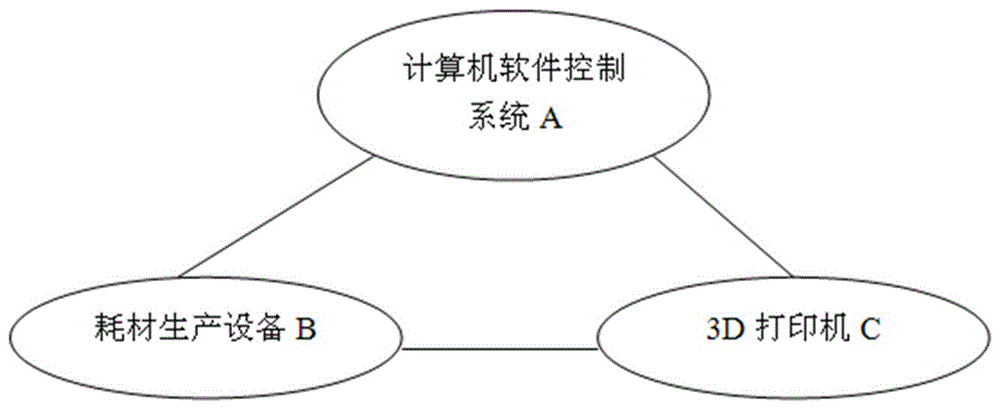

[0024] An integrated full-color 3D printing device, including computer software control system A, consumables production equipment B and 3D printer C; said computer software control system A includes 3D model design software and a central structure (not shown in the figure), The 3D model design software can be used to design full-color 3D product models, and automatically calculate the red, yellow, and blue ratios of the corresponding colors on the product. The central structure connects the computer with the consumable production equipment and the 3D printer.

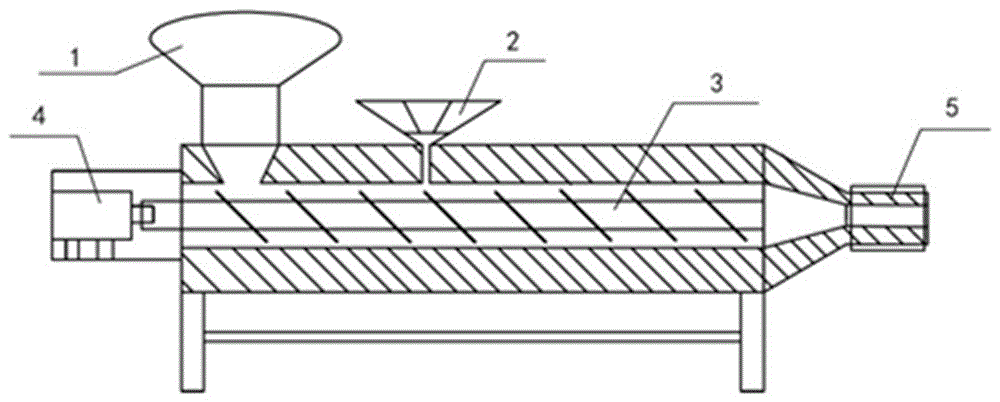

[0025] The 3D model design software is SolidWorks software. Consumables production equipment B is a desktop-level consumables production equipment, including: main material bin 1, toner bin 2, screw 3, motor 4, linear extrusion head 5, where main material bin 1 and color material bin 2 are located above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com