Hood adopting longitudinal-transverse reinforced rib structure and adopting RTM entire shaping technology and manufacturing method of hood

A technology of integral molding and manufacturing methods, applied in the direction of slender elements, building elements, etc., can solve the problems of poor continuity between vertical and horizontal reinforcement and panels, high requirements for secondary bonding technology, and unsatisfactory aviation use requirements, etc. The effect of good visual quality, improved continuity and connection strength, and high quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

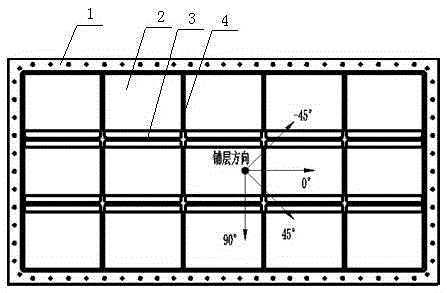

[0029] An RTM integrally formed vertically and horizontally reinforced structure cover, including a panel 2, a frame 1, a transverse rib 3 and a longitudinal rib 4, the panel 2 is arranged in the frame 1, the transverse rib 3 and the longitudinal rib 4 are both arranged on the panel 2, and the horizontal The ribs 3 and the longitudinal ribs 4 are arranged perpendicular to each other, and adopt the form that the transverse ribs 3 are continuous and the longitudinal ribs 4 are disconnected; the cover is made of carbon fiber fabric, and the fabric is shaped by using a hot-melt sizing agent, and the material is cut according to the lay-up design And cut the fabric, pave the preform on the cover mold to prepare the preform, then assemble and close the mold, adopt the RTM overall molding process, inject the resin into the cover mold where the preform is placed under the pressure of 2 to 10bar, and finally cure It is cured and formed in the furnace, and after the curing is completed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com