Crop straw manmade board and production method thereof

A crop straw and production method technology, applied in the field of crop straw wood-based panels and its production, can solve the problems of uneven moisture content of straw, large difference in shape of straw shavings, high energy consumption, etc., to ensure the appearance quality and physical and chemical properties, board Good physical and chemical properties, high yield of straw fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

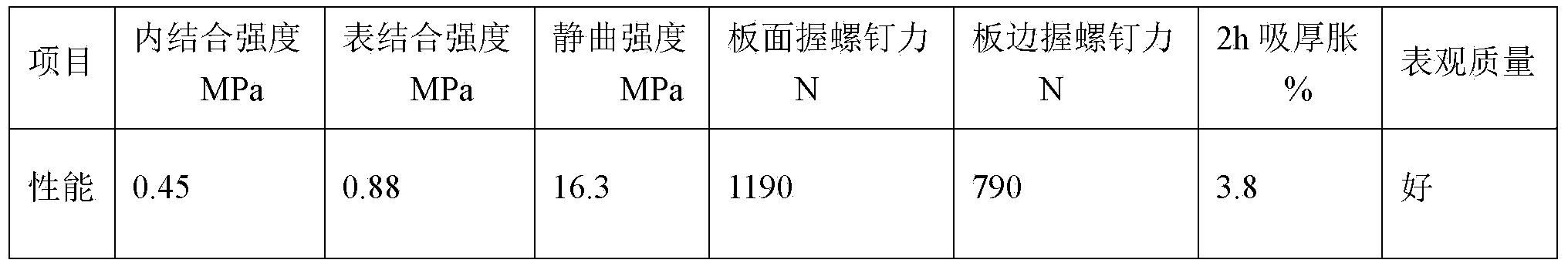

Embodiment 1

[0027] The purchased crop stalks have a moisture content of 20-30% and contain foreign matter such as soil, sand and gravel, and the crop stalks are used to produce straw man-made boards.

[0028] As an embodiment of the present invention, the production method of the crop straw man-made board includes the following steps:

[0029] (1) Use a grass cutter to cut the wheat straw into 20-40mm grass segments.

[0030] (2) A drum-type airflow dryer with impurity removal device is used to uniformly dry the grass section to reduce the moisture content of the grass section to 12-13%, while removing stones, soil, iron and other impurities. To prevent the debris from entering the next step of crushing.

[0031] Preferably, the drying system directly uses fresh air, the heat exchanger adopts a shell-and-tube heat exchanger, the exhaust gas discharge and recycling ratio is 1:1, the temperature of the air entering the dryer is 180°C, and the dryer screen is 25mm square The perforated screen, the ...

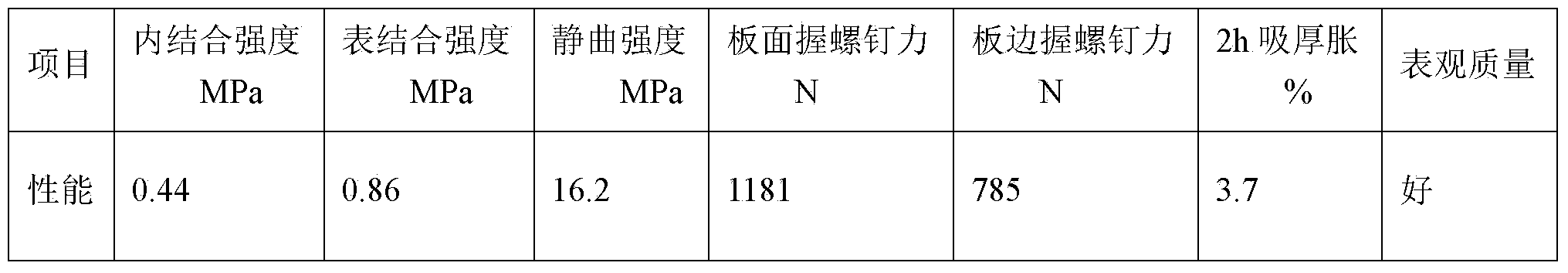

Embodiment 2

[0042] The purchased crop stalks have a moisture content of 20-30% and contain foreign matter such as soil, sand and gravel, and the crop stalks are used to produce straw man-made boards.

[0043] As an embodiment of the present invention, the production method of the crop straw man-made board includes the following steps:

[0044] (1) Use a grass cutter to cut the wheat straw into 30-50mm grass segments.

[0045] (2) A rotor dryer with impurity removal device is used to uniformly dry the grass section to reduce the moisture content of the grass section to 16-18%, while removing stones, soil, iron and other debris , In order to prevent debris from entering the next step of crushing process.

[0046] Preferably, the drying system directly uses fresh air, the heat exchanger adopts a shell-and-tube heat exchanger, the exhaust gas discharge and recycling ratio is 1:1.2, the temperature of the air entering the dryer is 185°C, and the dryer screen adopts a 25mm square The perforated screen...

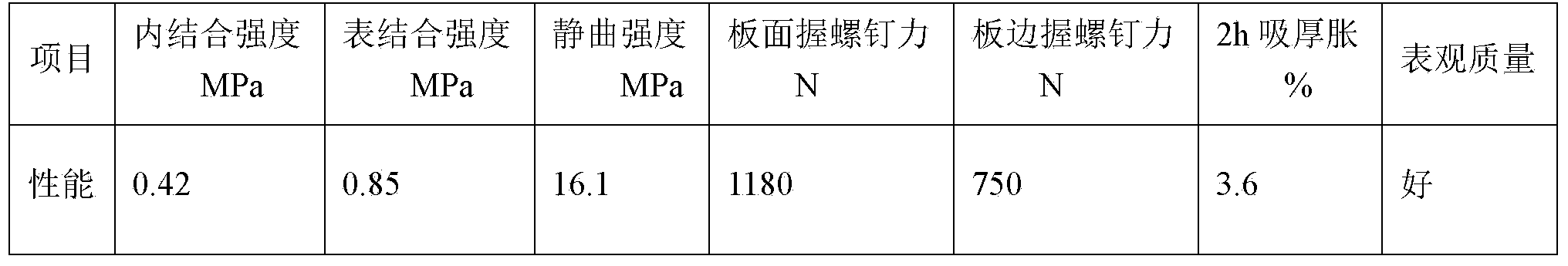

Embodiment 3

[0057] The purchased crop stalks have a moisture content of 20-30% and contain foreign matter such as soil, sand and gravel, and the crop stalks are used to produce straw man-made boards.

[0058] As an embodiment of the present invention, the production method of the crop straw man-made board includes the following steps:

[0059] (1) Use a grass cutter to cut the wheat straw into 45-60mm grass segments.

[0060] (2) Use a drum-type air-flow dryer with impurity removal device to uniformly dry the grass section, reduce the moisture content of the grass section to 8-12%, and remove stones, soil, iron and other impurities. To prevent the debris from entering the next step of crushing.

[0061] Preferably, the drying system directly uses fresh air, the heat exchanger adopts a shell-and-tube heat exchanger, the exhaust gas discharge and recycling ratio is 0.95:1, the temperature of the air entering the dryer is 180°C, and the dryer screen is 25mm square The perforated screen, the wind sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com