High-apparent mass blowing micro foaming automotive air duct material and preparation method thereof

An apparent quality, micro-foaming technology, applied in the field of materials, can solve problems such as poor internal and external appearance quality, achieve good dimensional stability, good rigidity, and reduce wind resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

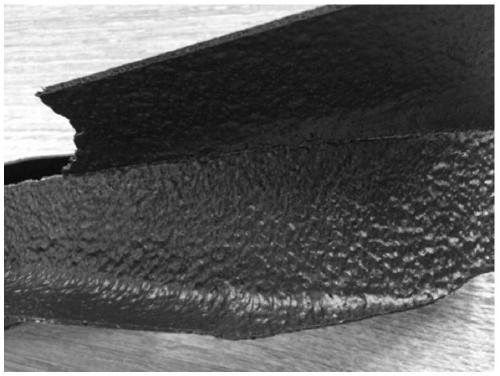

Image

Examples

Embodiment

[0040] A preparation method for blow molding micro-foamed automobile air duct material with high apparent quality, comprising the following steps:

[0041] Step 1: Add 60-85 parts of polyethylene, 1-10 parts of filler, 1-10 parts of hyperdispersant, 5-20 parts of toughening agent, 5-15 parts of foaming aid, and 1-5 parts of nucleating agent , 0.5-2 parts of other additives are mixed in the mixer for 2-4 minutes, added to the twin-screw extruder through the hopper, granulated at a temperature of 150-220 ° C, and the screw speed is 300-600 r / min to obtain blow-molded poly Vinyl composites;

[0042] Step 2: Fully mix the blowing agent in the high-mixer in advance according to the parts by weight, and then add it into the single-screw blow molding machine from the side feed port; at the same time, add the polyethylene composite material obtained in step 1 into the single-screw blow molding machine Blow molding machine barrel; blow molding at a temperature of 150-220°C to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com