Method for improving quality of continuous casting hollow bloom by applying composite alternating electromagnetic field and device

A technology of hollow tube and electromagnetic field, which is applied in the field of hollow metal tube blank preparation, can solve the problems of unobvious improvement of solidification structure, achieve good appearance quality, reduce manufacturing cost, and promote the effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

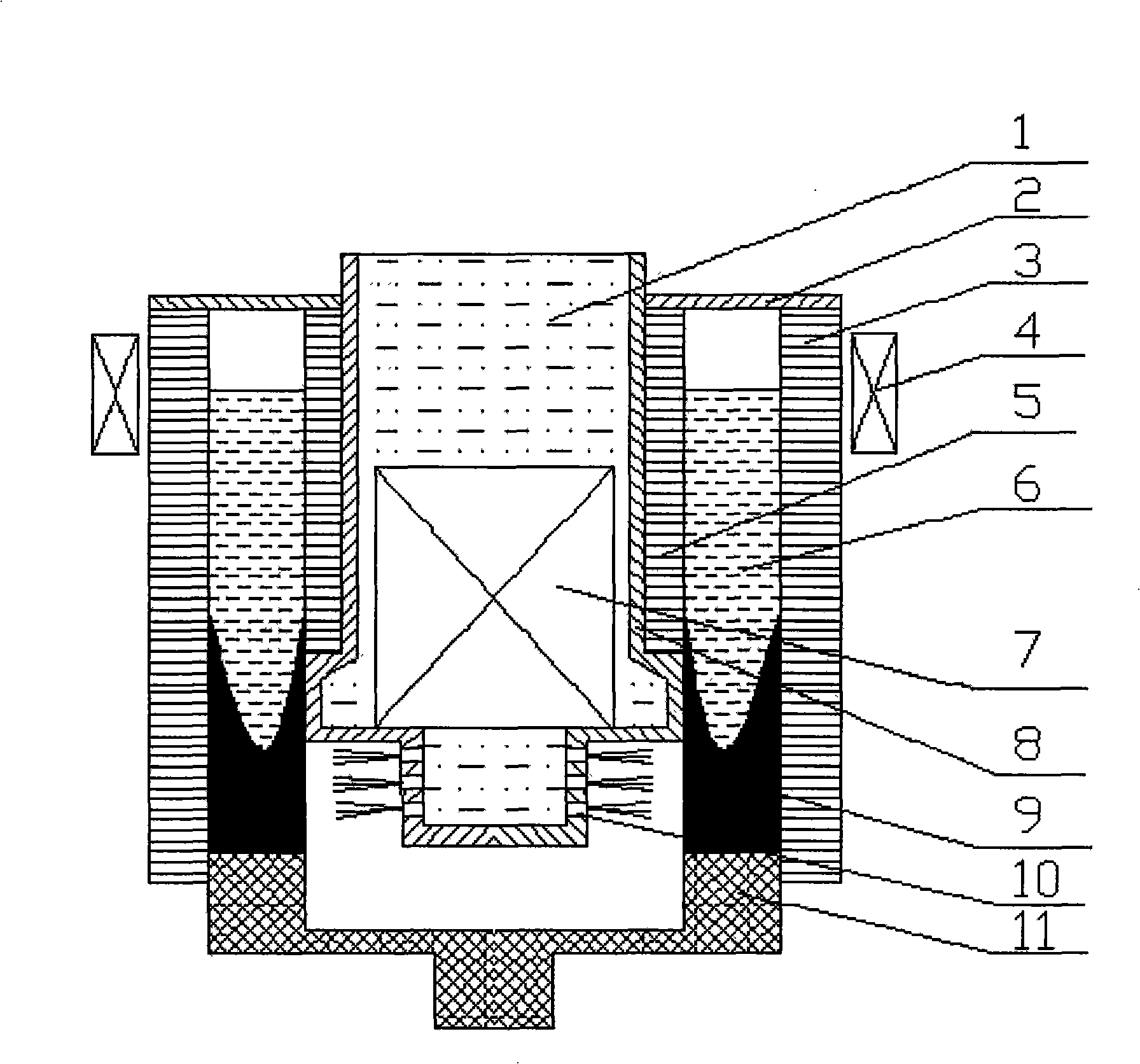

[0013] By placing a power frequency traveling wave magnetic field generator (7) in the inner crystallizer (5), an aluminum alloy tube blank of φ180×20mm is prepared, and the specific steps are as follows:

[0014] Step 1: Preparation of Convex Traveling Wave Magnetic Field Generator

[0015] The convex traveling wave magnetic field generator 7 adopts three pole pairs of coils, the current frequency is 50Hz, the phase angle is 120°, and the power supply is 1-3kW. The outwardly convex traveling wave magnetic field generator 7 is placed in the inner mold 5 so that the distance between the outer side of each coil and the inner side of the inner mold is 20 mm, and it is located near the initially solidified shell 9 of the hollow shell.

[0016] Step 2: Aluminum Alloy Billet Melting

[0017] The aluminum alloy billet is melted to 720-730°C in a resistance furnace, refined, degassed and slag removed, then kept warm for use.

[0018] Step 3: Electromagnetic continuous casting of hol...

Embodiment 2

[0023] By placing a power frequency rotating magnetic field generator 7 in the inner crystallizer 5, an aluminum alloy tube blank of φ180×20mm is prepared, and the specific steps are as follows:

[0024] Step 1: Preparation of the Convex Rotating Field Generator

[0025] The convex rotating magnetic field generator 7 adopts three pole pairs of coils, the current frequency is 50Hz, the phase angle is 120°, and the power supply is 1-3kW. The outwardly convex rotating magnetic field generator 7 is placed in the inner mold 5 so that the distance between the outside of each coil and the inside of the inner mold is 20mm, and it is located near the initial solidified shell 9 of the hollow shell.

[0026] Step 2: Aluminum Alloy Billet Melting

[0027] The aluminum alloy billet is melted to 720-730C in a resistance furnace, refined, degassed and slag removed, then kept warm for use.

[0028] Step 3: Electromagnetic continuous casting of hollow billets

[0029] Put the bottom mold 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com