Composite semi-active ultralow-frequency vibration isolating device

A semi-active, ultra-low frequency technology, used in shock absorbers, vibration suppression adjustment, springs, etc., to solve problems such as short working stroke and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

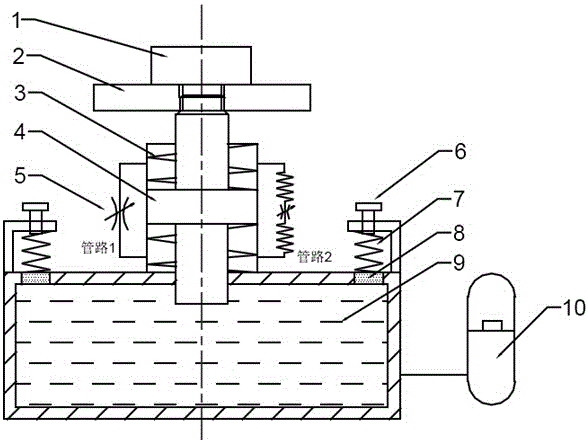

[0019] The design idea of the present invention is illustrated below by accompanying drawings.

[0020] Such as figure 1 As shown, in this embodiment, 1 is an external vibration source, and 2 is a connecting plate with a threaded hole in the middle for connecting with the piston rod 4 in the inerter. A centering spring 3 is arranged in the inertial container. The working medium in the inerter is magnetorheological fluid. The upper and lower cavities in the inerter are connected by an external pipeline. The external pipeline is divided into two parts. The left pipeline is arranged in a straight line, and the right pipeline is In a spiral arrangement, the two external pipelines are respectively connected with a magnetically controlled throttle valve 5 .

[0021] In this embodiment, the lower end of the piston rod 4 goes deep into the hydraulic buffer device 9, and the hydraulic buffer device 9 is filled with hydraulic oil of a certain pressure, and communicates with the exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com