Vacuum brazing method for radio fuze antenna radiator

A brazing method and radiator technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as easy breakage of solder tabs, uneven solder filling, and low assembly efficiency, so as to avoid uneven solder filling , improve the efficiency of vacuum brazing, and ensure the effect of welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

[0031] A vacuum brazing method for a radio fuze antenna radiator, comprising the following steps:

[0032] 1) Welding tabs are produced by wire cutting;

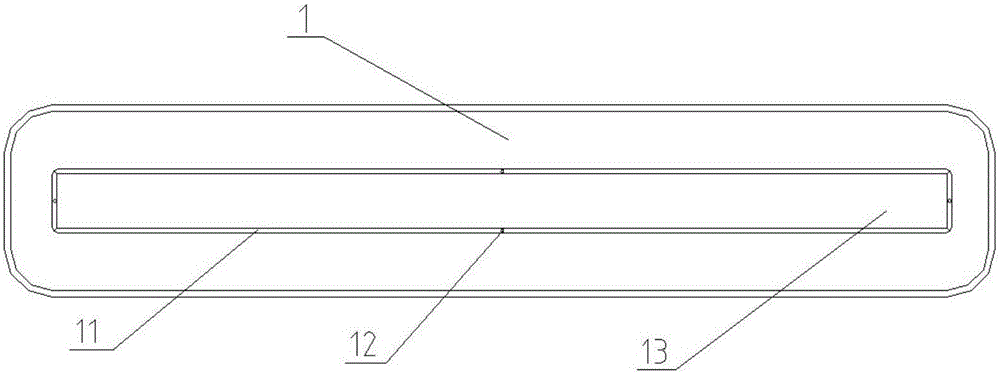

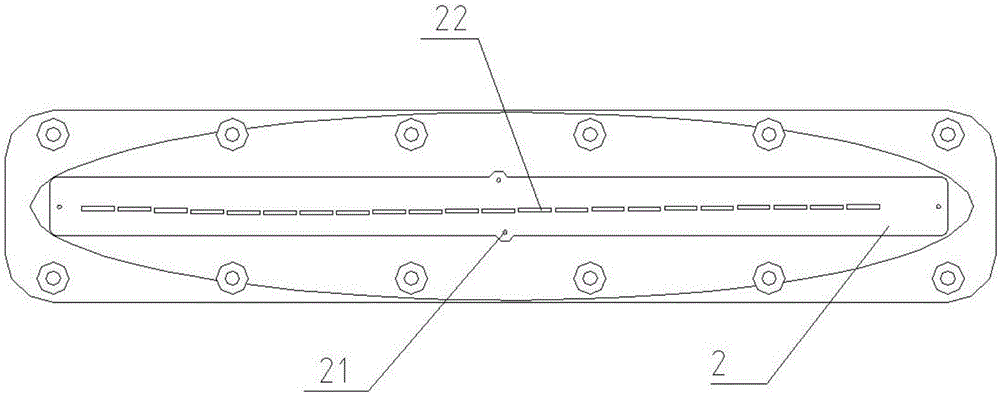

[0033] 2) Assemble the cavity and cover plate of the radiator as required. The structural diagram of cavity 1 and cover plate 2 is as follows figure 1 and figure 2 shown;

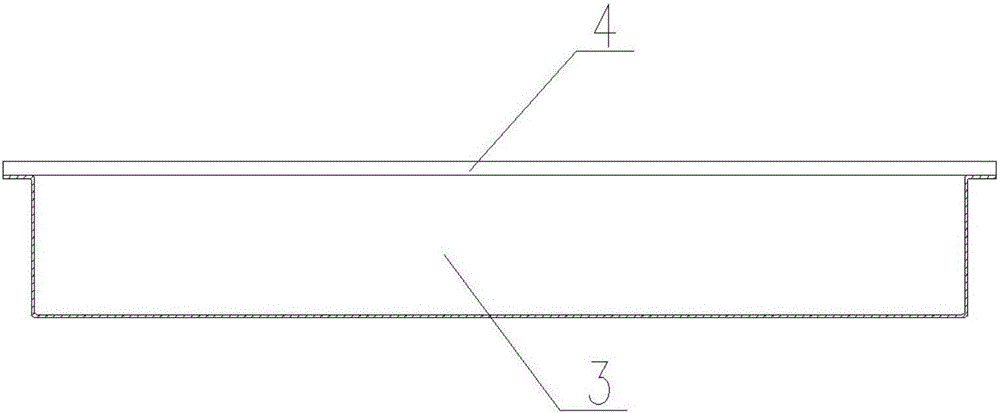

[0034] 3) Design the welding process box and welding tool, put the assembled radiator in the process box, put the welding tool in the vacuum furnace, and then put the process box on the welding tool; the structural diagram of the welding process box and welding tool like image 3 and Figure 4 shown;

[0035] 4) Carry out vacuum brazing to the radiator, the specific steps are as follows:

[0036] ①Raise the temperature from room temperature to 550°C, and the heating rate is 45±5°C / min;

[0037] ②Insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com