Testing method for cohesion performance of 3D printing building mortar

A test method, 3D printing technology, applied in the direction of measuring device, weighing by removing certain components, suspension and porous material analysis, etc., can solve the problem that the impermeability test is not suitable for the connection performance of 3D printing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

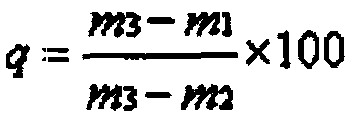

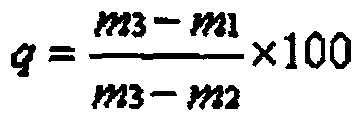

[0029] 3D printing construction mortar connection performance test method, through testing the porosity of layered printed mortar hardened specimens to characterize the quality of the connection between the printed mortar layer and the layer, the following steps are adopted:

[0030] (1) Specimen preparation: 3D printing equipment was used to print mortar layer by layer. After the mortar hardened, it was moved into the curing room for standard curing for 28 days. The obtained sample structure was as follows: figure 1 shown in figure 1 There are three layers in total, and the length, width, and height of each layer are 200mm, 40mm, and 15mm. The above dimensions can also be adjusted according to the working performance of the printing equipment and printing mortar;

[0031] (2) Porosity test:

[0032] a. Determination of dry quality: Take out the specimens that have been cured to age, in order to eliminate the interference of boundary conditions on the test results, saw off 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com