PVC structural foam and preparation method thereof

A PVC resin and foam technology, applied in the field of structural foam, can solve the problems of limited addition and compatibility, unable to meet the requirements of use, etc., to ensure uniformity and compatibility, increase the difficulty of heat-resistant modification, and fine cells. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

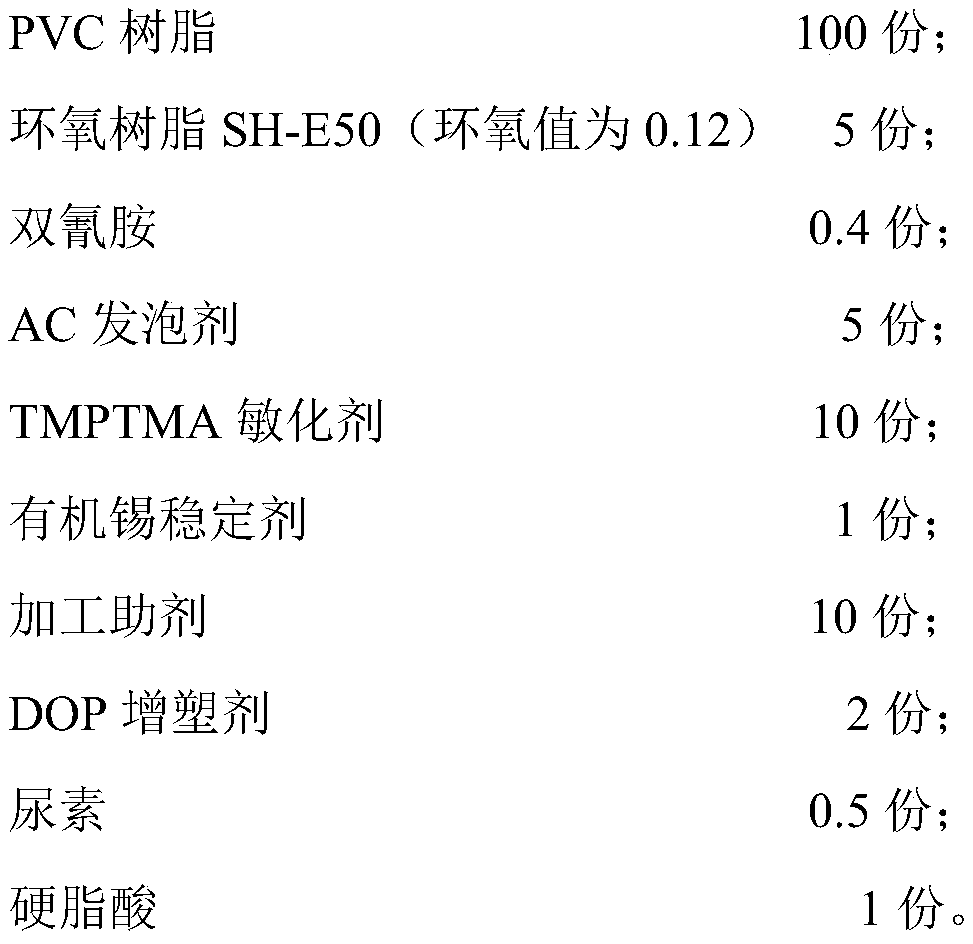

[0027] The PVC structural foam of this embodiment raw material components and proportioning are as follows in parts by weight:

[0028]

[0029] Preparation:

[0030] 1) First mix the epoxy resin SH-E50 with an epoxy value of 0.12 and the epoxy curing agent dicyandiamide according to the weight of the raw materials, and then mix them with the PVC resin evenly, then put in other raw material components in turn, and stir at a high speed to 100 After stirring at a low speed to 40°C, then kneading, pressing, and cooling in an open mill at 130°C to obtain a semi-finished plate;

[0031] 2) The semi-finished board obtained in step 1) was irradiated with a cobalt source for 14kGy, then foamed with hot air at 175°C for 30 minutes, cooled and shaped, and the finished PVC structural foam of Example 1 was prepared.

[0032] After testing, the compressive strength of the finished product of Example 1 is 1.07MPa, the Martin heat resistance temperature is 90.5°C, and the water absorptio...

Embodiment 2

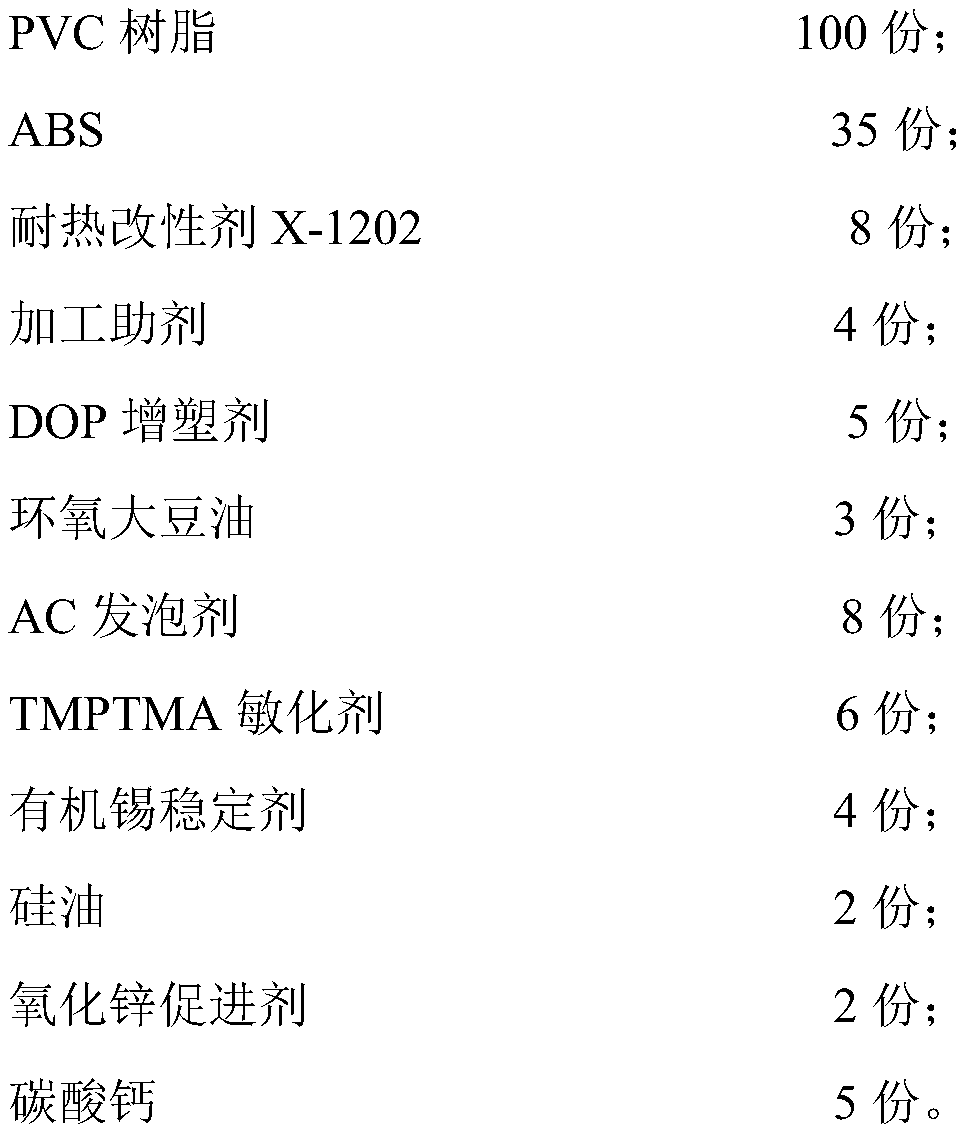

[0056] The PVC structural foam of this embodiment raw material components and proportioning are as follows in parts by weight:

[0057]

[0058] Preparation:

[0059] 1) First mix the epoxy resin with an epoxy value of 0.05 and the SH-201 curing agent evenly with the PVC resin according to the weight of the raw materials, and then put in other raw material components in turn, stir at high speed to 100°C, and then turn to low speed stirring to 40°C, and then kneaded, pressed and formed, and cooled by an open mill at 145°C to obtain a semi-finished plate;

[0060] 2) The semi-finished board obtained in step 1) was irradiated with cobalt source 4kGy, then molded and foamed at 200°C and 11MPa for 13min, cooled and shaped, and the finished PVC structural foam of Example 2 was prepared.

[0061] After testing, the compressive strength of the finished product of Example 2 is 1.16MPa, the Martin heat resistance temperature is 91.8°C, and the water absorption rate is 1.3%.

Embodiment 3

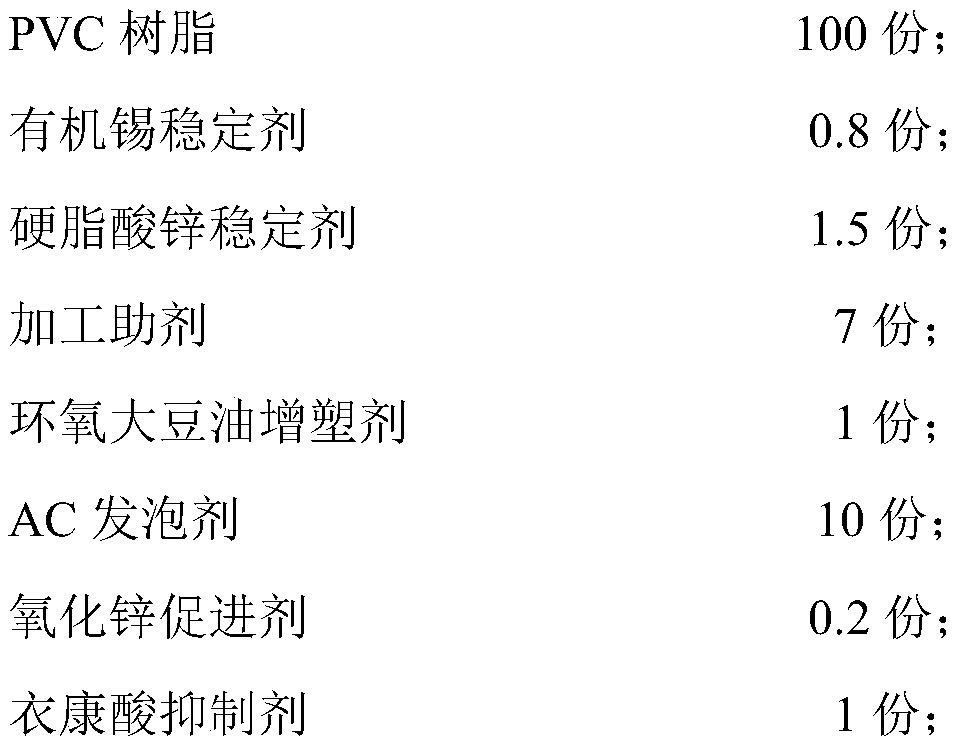

[0063] The PVC structural foam of this embodiment raw material components and proportioning are as follows in parts by weight:

[0064]

[0065]

[0066] Preparation:

[0067] 1) Mix the epoxy resin E51 and the SH-201 curing agent evenly according to the weight of the raw materials, and then mix them evenly with the PVC resin, then put in other raw material components in turn, stir at a high speed to 100°C, then turn to a low speed to 40°C, and then After kneading by a 120°C open mill, molding and pressing out the sheet, the semi-finished sheet is obtained;

[0068] 2) The semi-finished board obtained in step 1) was irradiated with a cobalt source of 80 kGy, then molded and foamed at 210° C. and 10 MPa for 4 minutes, cooled and shaped, and the finished PVC structural foam of Example 3 was prepared.

[0069] After testing, the compressive strength of the finished product of Example 3 is 1.80 MPa, the Martin heat resistance temperature is 98.5° C., and the water absorptio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com