Variable-density ethylene propylene diene monomer thermal insulation functional material and preparation method thereof

A technology of EPDM rubber and functional materials, applied in the direction of rubber layered products, chemical instruments and methods, layered products, etc., can solve the problem that the light weight of the heat insulation layer cannot meet the requirements of special fields, and cannot cope with harsh and harsh conditions environment, joint peeling, etc., to improve the ability to resist harsh environments, stabilize the structure, and improve the effect of connection force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

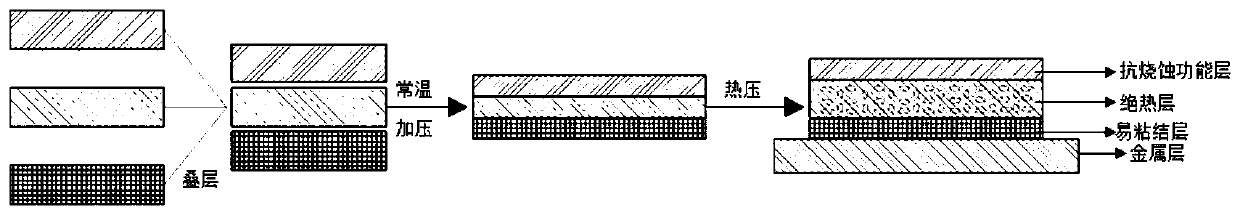

[0032] This embodiment discloses a variable-density EPDM rubber heat-insulating functional material, which is composed of three layers: an anti-ablation functional layer, a heat-insulating layer, and an easy-bonding layer, and the thickness ratio of the three layers is 1:2:1, wherein:

[0033] The composition of the anti-ablation functional layer is calculated in parts by mass: EPDM rubber: 100 parts, fumed silica: 20 parts, kaolin: 20 parts, talcum powder: 25 parts, Al(OH) 3 : 15 parts, zinc oxide: 5 parts, stearic acid: 2 parts, paraffin oil: 10 parts, tetramethylthiuram disulfide (TMTD): 1.5 parts, benzothiazole disulfide (DM): 1 part, Sulfur: 1.5 parts, 3mm chopped carbon fiber: 8 parts.

[0034] The composition of the thermal insulation layer is calculated in parts by mass: EPDM rubber: 100 parts, fumed silica: 25 parts, zinc oxide: 5 parts, stearic acid: 3 parts, paraffin oil: 15 parts, disulfide Tetramethylthiuram (TMTD): 1.5 parts, benzothiazole disulfide (DM): 1 part...

Embodiment 2

[0043] This embodiment discloses a variable-density EPDM rubber heat-insulating functional material, which is composed of three layers: an anti-ablation functional layer, a heat-insulating layer, and an easy-bonding layer, and the thickness ratio of the three layers is 1:2:1, wherein:

[0044] The composition of the anti-ablation functional layer is calculated in parts by mass: EPDM rubber: 100 parts, fumed silica: 25 parts, kaolin: 20 parts, talcum powder: 20 parts, Al(OH) 3 : 15 parts, zinc oxide: 6 parts, stearic acid: 2 parts, paraffin oil: 15 parts, tetramethylthiuram disulfide (TMTD): 1.5 parts, benzothiazole disulfide (DM): 1 part, Sulfur: 1.5 parts, 3mm chopped high silica glass fiber: 8 parts.

[0045] The composition of the thermal insulation layer is calculated in parts by mass: EPDM rubber: 100 parts, fumed silica: 30 parts, zinc oxide: 5 parts, stearic acid: 2 parts, paraffin oil: 15 parts, disulfide Tetramethylthiuram (TMTD): 1.5 parts, benzothiazole disulfide (...

Embodiment 3

[0054] This embodiment discloses a variable-density EPDM rubber heat-insulating functional material, which is composed of three layers: an anti-ablation functional layer, a heat-insulating layer, and an easy-bonding layer, and the thickness ratio of the three layers is 1:2:1, wherein:

[0055] The composition of the anti-ablation functional layer is calculated in parts by mass: EPDM rubber: 100 parts, fumed silica: 30 parts, kaolin: 25 parts, talcum powder: 30 parts, Al(OH) 3 : 10 parts, zinc oxide: 5 parts, stearic acid: 2 parts, paraffin oil: 15 parts, tetramethylthiuram disulfide (TMTD): 1.5 parts, benzothiazole disulfide (DM): 1 part, Sulfur: 1.5 parts, 3mm chopped aramid fiber: 8 parts.

[0056] The composition of the thermal insulation layer is calculated in parts by mass: EPDM rubber: 100 parts, fumed silica: 25 parts, zinc oxide: 5 parts, stearic acid: 2 parts, paraffin oil: 20 parts, disulfide Tetramethylthiuram (TMTD): 1.5 parts, benzothiazole disulfide (DM): 1 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com