Preparation method for chlorinated polyvinyl chloride foaming board

A technology of chlorinated polyvinyl chloride and foamed boards, which is applied in the field of foaming agents, can solve the problems of uneven surface of foamed boards, large cells of foamed boards, and uneven performance, and achieve fine and uniform cells, Good heat resistance and fire resistance, the effect of improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

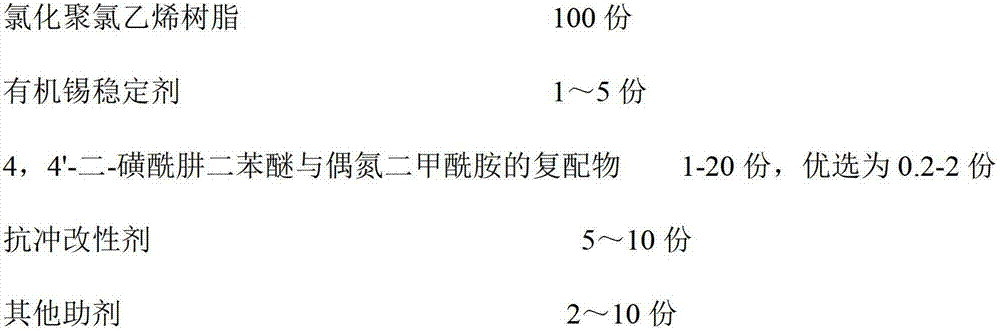

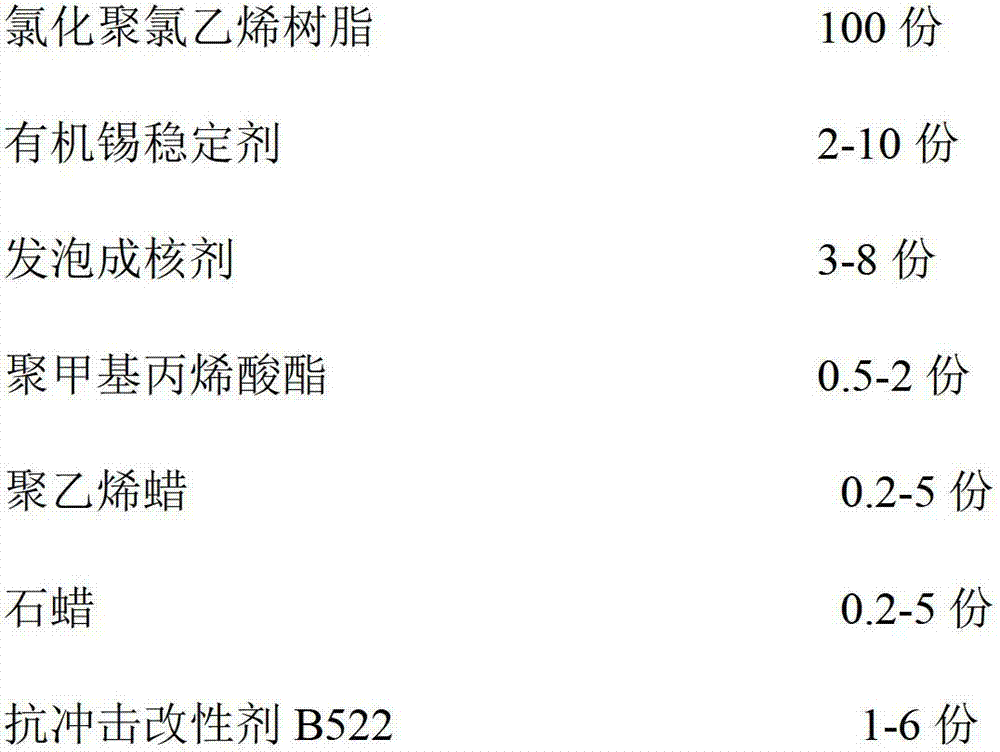

Method used

Image

Examples

Embodiment Construction

[0022] Processing performance test method:

[0023] (1) Rheological test: The mixing temperature of the rheometer (Thermo Hakke Polylab System) was set at 185°C, the rotor speed was 30 rpm, and 68 grams of the mixture was weighed and added to the mixer to start the rheometer until After the torque is constant for 5 minutes, the plasticizing time and equilibrium temperature are read.

[0024] (2) The above-mentioned mixture is pressed into a foam board by a vulcanizing machine, and the sample is prepared according to the test standard. The Vicat softening point is tested according to the ASTMD1525-00 standard, and the notched impact strength is tested according to the GB / T1043-93 standard.

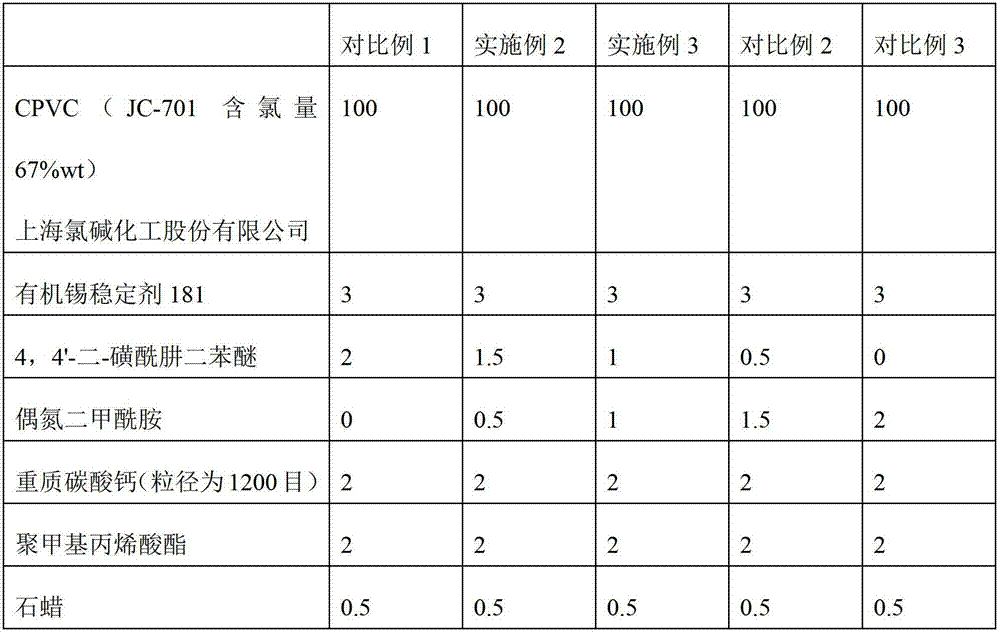

[0025] The following is further described by examples and comparative examples, but the present invention is not limited to these examples.

[0026] The preparation method of embodiment and comparative example is as follows:

[0027] Add chlorinated polyvinyl chloride resin, organic tin s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com