Preparations of conductive sponge and conductive latex solution

A technology of latex solution and conductive sponge, applied in the field of preparation of sponge and latex solution, can solve the problems of large cells, poor compression and resilience, and unevenness of conductive sponge, and achieve fine and uniform cells, good compressive strength and good compression strength. The effect of resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described below in conjunction with accompanying drawing and embodiment:

[0021] The principle of the preparation conductive sponge that the present invention adopts is:

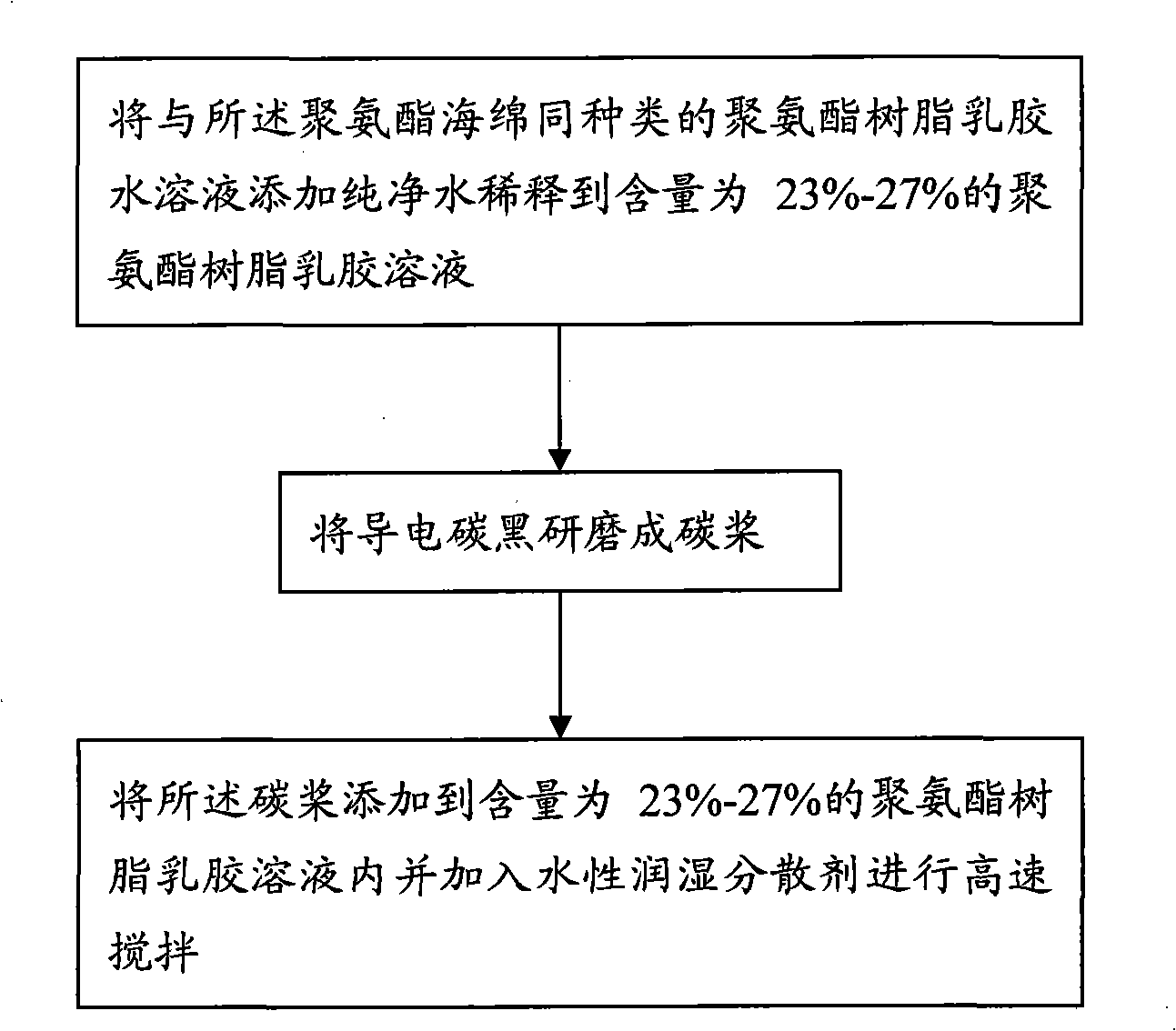

[0022] Select the polyurethane resin latex aqueous solution of the same type as the polyurethane (PU) sponge, add a conductive agent to disperse into the polyurethane resin latex aqueous solution to make it conductive, use the principle of similar compatibility of polymer materials, after drying the polyurethane resin latex containing the conductive agent, It will be firmly attached to the surface of the open-cell polyurethane sponge, so that the inside and outside of the polyurethane sponge will be covered by conductive tiny polyurethane resin particles, and the sponge will become a conductive material.

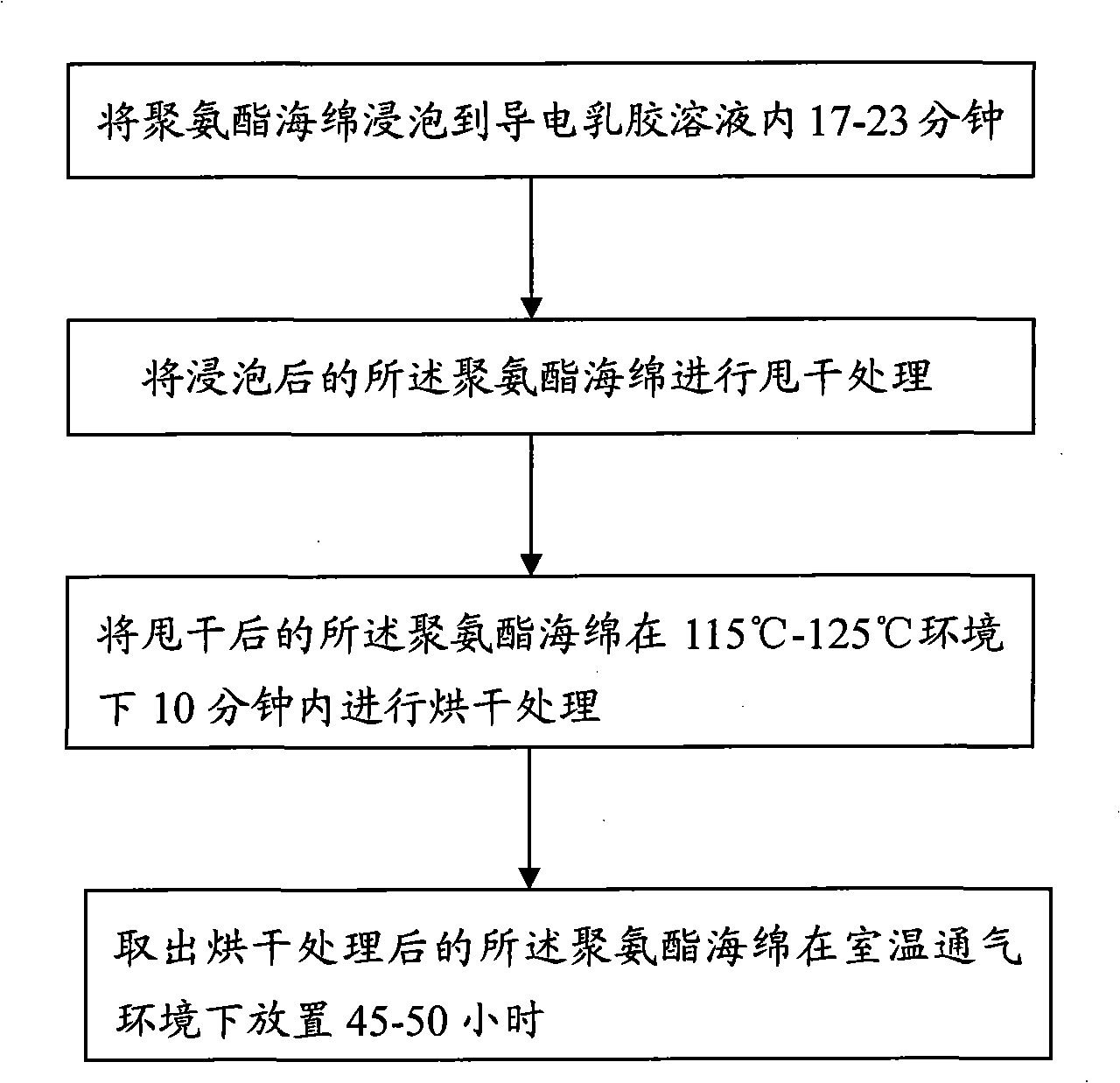

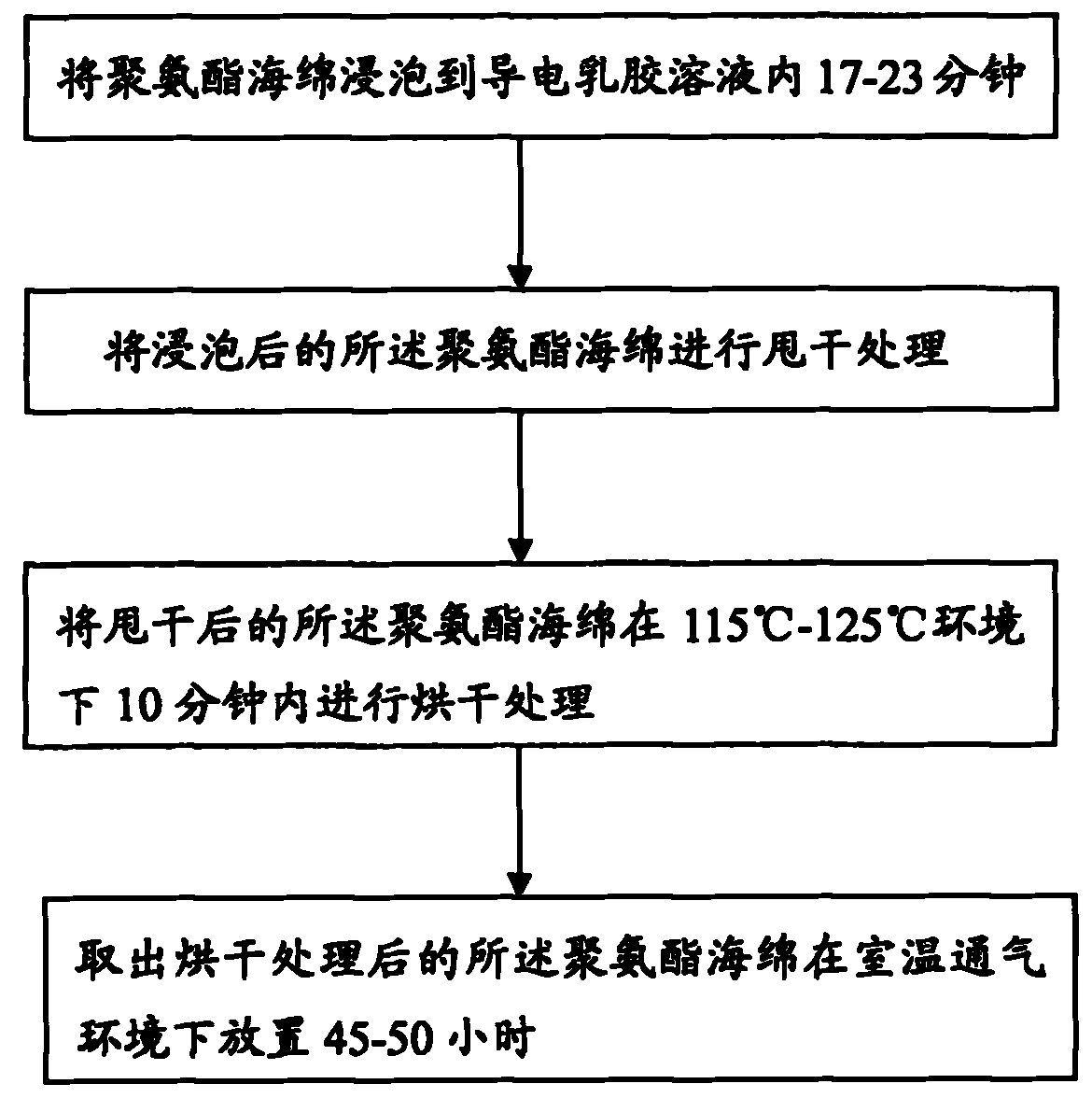

[0023] For details, please refer to figure 1 The preparation method flowchart of conductive sponge described in the preparation method of a kind of conductive sponge and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com