Composite foaming agent for soft PVC foam material

A technology of composite foaming agent and foaming material, applied in the field of foaming agent, can solve the problems of small heat release and slow decomposition, and achieve the effect of gentle decomposition, strong suddenness and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] A composite foaming agent for soft PVC foaming materials, consisting of the following raw materials in parts by weight:

[0032] Azodicarbonamide 5 parts

[0033] N,N'-Dinitrosopentamethylenetetramine 2.2 parts

[0034] Cetyltrimethylammonium bromide 1.5 parts

[0035] Sodium bicarbonate 2 parts

[0036] 3 parts sodium citrate

[0037] Zinc carbonate 1.2 parts

[0038] Chromium sulfate 0.8 parts

[0039] 0.6 parts of lead stearate

[0040] 3 parts glycerin

[0041] Polyoxypropylene glycol 12 parts

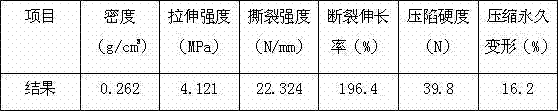

PUM

| Property | Measurement | Unit |

|---|---|---|

| compression ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com