Open-pore chemical-crosslinked polyolefin foam material and preparation method therefor

A polyolefin foaming and chemical cross-linking technology is applied in the field of open-cell chemical cross-linked polyolefin foam materials and their preparation, which can solve the problems of increased equipment investment, rough material surface, complicated production process, etc. The effect of fine and uniform cells and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

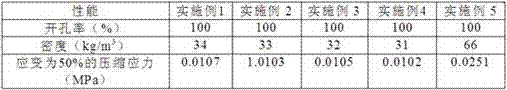

Examples

Embodiment 1

[0030] A closed-cell chemically cross-linked polyolefin foam material is composed of polyolefin material, main foaming agent, foaming agent activator, cross-linking agent, cross-linking accelerator, inorganic filler, lubricant through banburying, extrusion, Calendered, foamed, trimmed and rolled.

[0031] The preparation method of described closed-cell chemically cross-linked polyolefin foam material comprises the following steps:

[0032] (1) Mix 30kg low-density polyethylene, 7.5kg high-density polyethylene, 8.5kg azodicarbonamide, 0.25kg dicumyl peroxide, 0.25kg triallyl cyanurate, 3kg talcum powder, 0.25 kg calcium stearate and 0.25kg zinc oxide were banburyed at 115°C for 15 minutes with a banbury mixer, and the rotor speed was 40r / min;

[0033] (2) Put the mixed material into a single-screw extruder equipped with a T-shaped die, melt and extrude it to make a sheet. The temperature of the extruder is 125°C, and the screw speed is 12r / min;

[0034] (3) The extruded sheet...

Embodiment 2

[0039] A closed-cell chemically cross-linked polyolefin foam material is composed of polyolefin material, main foaming agent, foaming agent activator, cross-linking agent, cross-linking accelerator, inorganic filler, lubricant through banburying, extrusion, Calendered, foamed, trimmed and rolled.

[0040] The preparation method of described closed-cell chemically cross-linked polyolefin foam material comprises the following steps:

[0041] (1) 35kg low-density polyethylene, 5kg ethylene-vinyl acetate copolymer, 8.5kg azodicarbonamide, 0.3kg dicumyl peroxide, 0.25kg triallyl cyanurate, 0.5kg carbon black , 0.25kg of calcium stearate, 0.25kg of zinc oxide were banburyed at 110°C for 15min with an internal mixer, and the rotor speed was 40r / min;

[0042](2) Put the mixed material into a single-screw extruder equipped with a T-shaped die, melt and extrude it to make a sheet. The temperature of the extruder is 120°C, and the screw speed is 12r / min;

[0043] (3) The extruded sheet...

Embodiment 3

[0048] A closed-cell chemical cross-linked polyolefin foam material is composed of polyolefin material, main foaming agent, auxiliary foaming agent, activator of foaming agent, cross-linking agent, cross-linking accelerator, inorganic filler, lubricant through dense Refined, extruded, calendered, foamed, trimmed, and rolled.

[0049] The preparation method of described closed-cell chemically cross-linked polyolefin foam material comprises the following steps:

[0050] (1) 35.5kg of low-density polyethylene, 5kg of ethylene-vinyl acetate copolymer, 8.5kg of azodicarbonamide, 1kg of microsphere blowing agent, 0.3kg of dicumyl peroxide, and 0.25kg of triallyl cyanide Urate ester, 0.5kg carbon black, 0.25kg calcium stearate, 0.25kg zinc oxide were mixed in an internal mixer at 110°C for 15 minutes, and the rotor speed was 40r / min;

[0051] (2) Put the mixed material into a single-screw extruder equipped with a T-shaped die, melt and extrude it to make a sheet. The temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com