XPE (crosslinked polyethylene) foaming material and preparation method thereof

A foaming material and foaming agent technology, applied in the field of XPE foaming material and its preparation, can solve the problems of large cells, short service life and high cost, achieve uniform and fine cells, improve compatibility and production efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

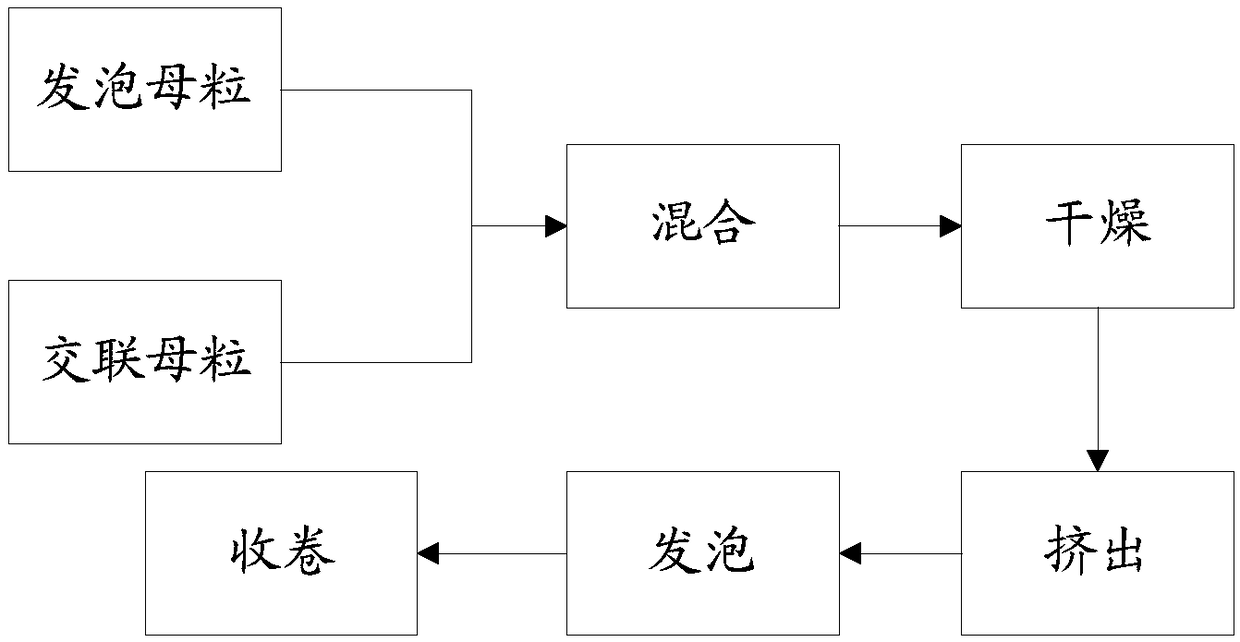

[0031] The present invention also provides a kind of preparation method of above-mentioned XPE foam material, comprises the following steps:

[0032] Step 1. Mix the foaming agent OBSH, foaming agent BIH 40, curing agent, compound foaming aid and surface treatment agent in a high-speed mixer for 3 to 5 minutes at a mixing speed of 200r / min to 400r / min. Prepare modified blowing agent;

[0033] Step 2. Adjust the temperature of the internal mixer to 70-110°C, add low-density polyethylene and linear low-density polyethylene to the internal mixer for the first time for internal mixing, add the modified foaming agent obtained in step 1 after complete melting, and continue to close Refining for 3 to 5 minutes, and then granulating the mass of materials after banburying through a twin-screw granulator to obtain foam masterbatch;

[0034] Step 3. Adjust the temperature of the internal mixer to 70-110°C, add low-density polyethylene and linear low-density polyethylene to the internal ...

Embodiment 1

[0042] A kind of XPE foaming material, comprises the raw material of following weight part: Calculate as 100 parts by total weight part, 54 parts of low-density polyethylene, 36 parts of linear low-density polyethylene, 8 parts of modified blowing agent, crosslinking agent 0.65 part, 0.35 part of auxiliary crosslinking agent, 1 part of masterbatch; Said crosslinking agent is di-tert-butyl peroxide, and said auxiliary crosslinking agent is TAIC;

[0043] The modified foaming agent includes foaming agent OBSH (4,4'-oxobisbenzenesulfonyl hydrazide), foaming agent BIH 40, curing agent, compound foaming aid and surface treatment agent, the foaming agent The weight ratio of foaming agent OBSH, foaming agent BIH 40, curing agent, compound foaming aid and surface treatment agent is 12:8:1:2:2; the curing agent is methylsulfate, and the compound Adding foaming aids is urea, stearic acid and sodium hydroxide, the ratio of the three is 5:2:1, the surface treatment agent is paraffin oil a...

Embodiment 2

[0053] A kind of XPE foaming material, comprises the raw material of following weight part: Calculate with total weight part as 100 parts, low density polyethylene 54.6 parts, linear low density polyethylene 27.4 parts, modified foaming agent 15 parts, crosslinking agent 0.66 part, 0.34 part of auxiliary crosslinking agent, 2 parts of color masterbatch; Described crosslinking agent is BIPB, and described auxiliary crosslinking agent is TAIC;

[0054] The modified foaming agent includes foaming agent OBSH (4,4'-oxobisbenzenesulfonyl hydrazide), foaming agent BIH 40, curing agent, compound foaming aid and surface treatment agent, the foaming agent The weight ratio of foaming agent OBSH, foaming agent BIH 40, curing agent, compound foaming aid and surface treatment agent is 60:40:3:5:15; The foaming aid is zinc hydroxide, stearic acid and sodium hydroxide, and the ratio of the three is 4:3:2. The surface treatment agent is paraffin oil and white oil, and the ratio of the two is 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com