Polyurethane resin used for slow-recovery sponge, and preparation method and application thereof

A technology of polyurethane resin and slow-rebound sponge, which is applied in the fields of polyurethane resin for slow-rebound sponge and its preparation and application, can solve the problem of high production cost, achieve the effects of low cost, reduced resource waste and wide adjustable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

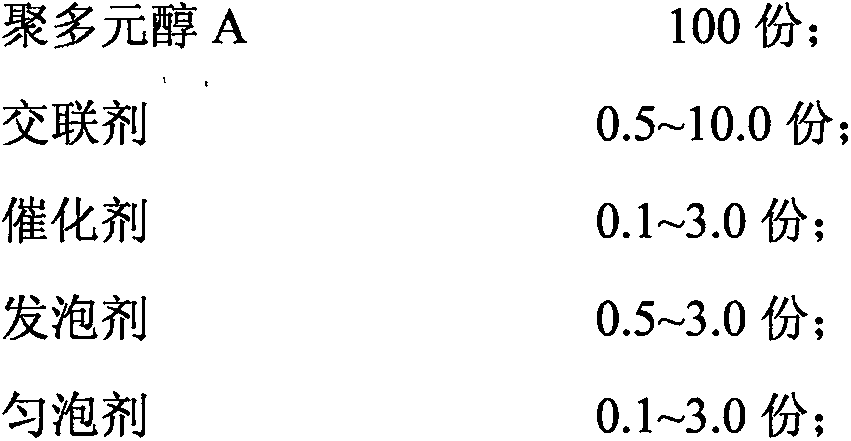

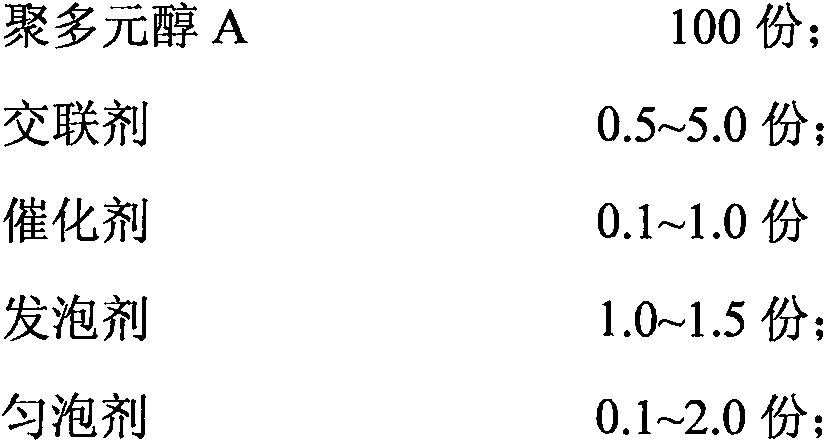

Method used

Image

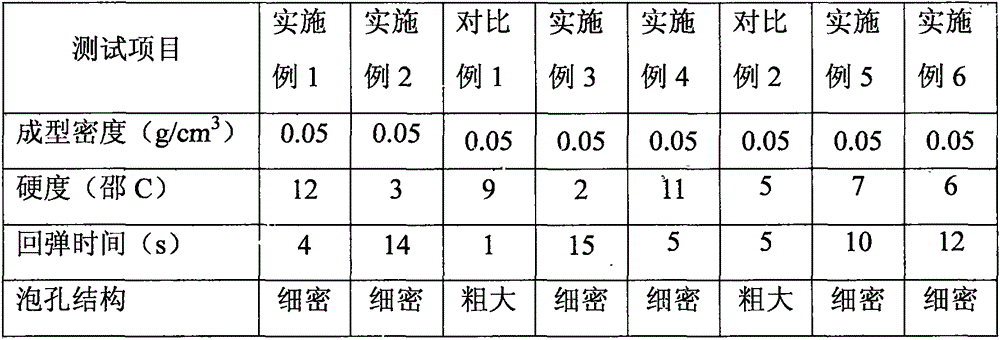

Examples

Embodiment 1

[0055] The polyoxyethylene-oxypropylene trihydric alcohol (number average molecular weight is 6000) of 144.3kg, the polyoxypropylene ether trihydric alcohol (number average molecular weight 300) of 86.6kg, the styrene graft copolymerized polyoxyethylene-oxypropylene of 46.2kg Trihydric alcohol (the number average molecular weight is 6000), 1.39kg ethylene glycol, the ethylene glycol solution of the triethylenediamine of 0.22kg, the bis(dimethylaminoethyl) ether of 0.89kg 70wt% and 30wt% ash A solution made of dipropylene glycol, 2.77kg of water and 0.28kg of silicone foam stabilizer were reacted at 50°C for 2.5h, cooled to 40°C, and mixed for 1.5h to obtain polyurethane resin component A.

[0056] With 119.8kg of diphenylmethane diisocyanate, 39.8kg of carbodiimide modified diphenylmethane diisocyanate, 1.99kg of polyoxyethylene-oxypropylene trihydric alcohol (number average molecular weight is 6000) and 0.0040kg of Phosphoric acid was reacted at 65°C for 3 hours to obtain com...

Embodiment 2

[0060]The polyoxyethylene-oxypropylene trihydric alcohol (number average molecular weight is 6000) of 144.3kg, the polyoxypropylene ether trihydric alcohol (number average molecular weight 300) of 86.6kg, the styrene graft copolymerized polyoxyethylene-oxypropylene of 46.2kg Trihydric alcohol (the number average molecular weight is 6000), 1.39kg ethylene glycol, the ethylene glycol solution of the triethylenediamine of 0.22kg, the bis(dimethylaminoethyl) ether of 0.89kg 70wt% and 30wt% ash A solution made of dipropylene glycol, 2.77kg of water and 0.28kg of silicone foam stabilizer were reacted at 50°C for 2.5h, cooled to 40°C, and mixed for 1.5h to obtain polyurethane resin component A.

[0061] With 18.7kg of diphenylmethane diisocyanate, 6.21kg of carbodiimide modified diphenylmethane diisocyanate, 0.30kg of polyoxyethylene-oxypropylene trihydric alcohol (number average molecular weight is 6000) and 0.0009kg of Phosphoric acid was reacted at 65°C for 3 hours to obtain compo...

Embodiment 3

[0065] The polyoxyethylene-oxypropylene trihydric alcohol (number average molecular weight is 10000) of 89.8kg, the polyoxypropylene ether trihydric alcohol (number average molecular weight 1000) of 11.2kg, the acrylonitrile graft copolymerized polyoxyethylene-oxypropylene of 101.0kg Trihydric alcohol (the number average molecular weight is 10000), 2.02kg ethylene glycol, the ethylene glycol solution of the triethylenediamine of 1.01kg, the bis (dimethylaminoethyl) ether of 70wt% and 30wt% ash of 1.01kg A solution made of dipropylene glycol, 3.03kg of water and 4.04kg of silicone foam stabilizer were reacted at 60°C for 1.5h, cooled to 45°C, and mixed for 1.0h to obtain the polyurethane resin component A.

[0066] With 7.99kg of diphenylmethane diisocyanate, 2.00kg of carbodiimide modified diphenylmethane diisocyanate, 2.00kg of polyoxyethylene-oxypropylene trihydric alcohol (number average molecular weight is 10000) and 0.002kg of Phosphoric acid was reacted at 75°C for 2 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com