High temperature-resistant imide-polyvinyl chloride alloy structure foam and preparation method thereof

A technology of polyvinyl chloride and polyvinyl chloride resin, which is applied in the field of imide-polyvinyl chloride alloy structural foam and its preparation, can solve the problems of inability to effectively increase the use temperature of polyvinyl chloride structural foam and the promotion of production costs, and achieve Small size deformation, wide application range, fine and uniform cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

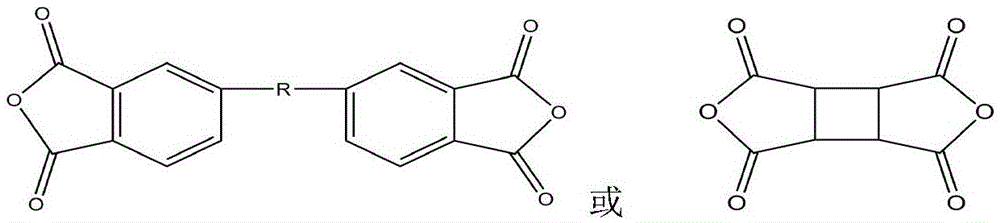

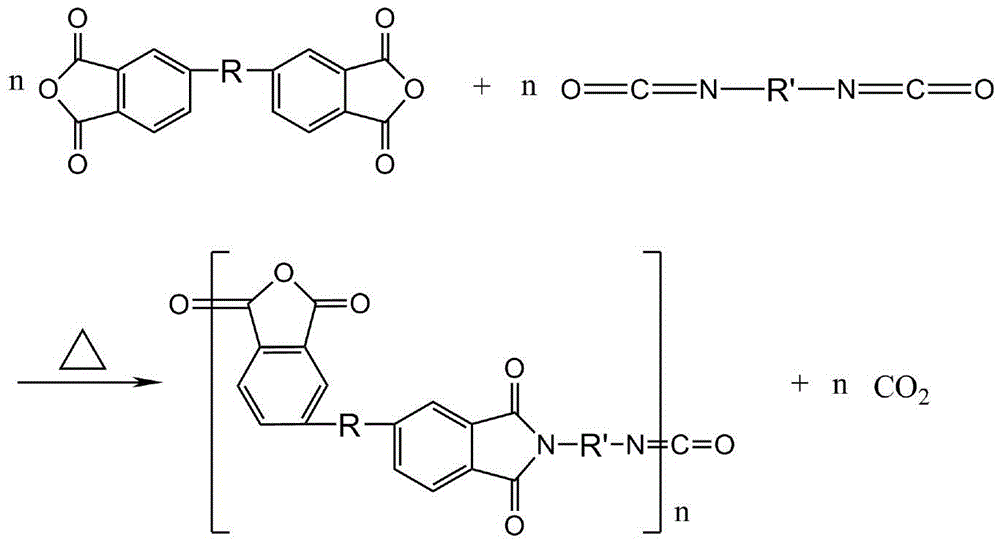

Method used

Image

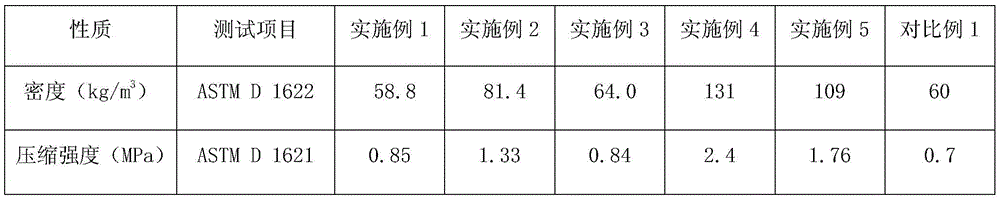

Examples

preparation example Construction

[0037] A preparation method of high temperature resistant imide-polyvinyl chloride alloy structural foam, comprising the following steps:

[0038] (1) get polyvinyl chloride resin, organic dianhydride, isocyanate, stabilizer and initiator and mix uniformly to obtain mixture;

[0039] (2) injecting the mixture into a mould, and forming a semi-foamed embryo body at a temperature of 150-200° C. and a pressure of 8-30 MPa;

[0040] (3) keep the pressure constant, make the semi-foamed embryo body cool to normal temperature and then release the pressure to obtain the elastic massive embryo body;

[0041] (4) Heat and expand the obtained elastic block-shaped embryo body in a drying oven at a temperature of 70-100° C. to obtain a semi-finished product;

[0042] (5) the semi-finished product obtained in step (4) is placed in a hot water bath or steam to expand to obtain block foam;

[0043] (6) Cool the block foam to room temperature, and then solidify it in hot water spray or steam ...

Embodiment 1

[0045] 1. Recipe

[0046] A high temperature resistant imide-polyvinyl chloride alloy structural foam, which includes the following components by weight: 100 parts of polyvinyl chloride resin, 27 parts of bisphenol A diether dianhydride, 56 parts of hexamethylene diisocyanate 1 part, 3 parts of azobisisobutyronitrile, 1 part of azodicarbonamide, and 2 parts of epoxy resin.

[0047] 2. Preparation method

[0048] Mix the above raw materials evenly and pour them into the mold, put them into a 180°C, 30MPa plate press and heat them for 54 minutes to cool to room temperature, then take them out, and then place the embryo body in a dry oven at 100°C to expand to about 5 to 6 times. Then transfer it to a water bath at 97±2°C for about 3 hours to reach the required density, and then solidify it in a hot water spray room at 70°C for 5 days to obtain a rigid imide-polyvinyl chloride alloy structural foam.

Embodiment 2

[0050] 1. Recipe

[0051]A high temperature resistant imide-polyvinyl chloride alloy structural foam, which includes the following components in parts by weight: 100 parts of polyvinyl chloride resin, 18 parts of pyromellitic dianhydride, 4.5 parts of azobisisobutyronitrile, 1.5 parts of azodicarbonamide, 38 parts of isophorone diisocyanate, and 1 part of epoxy resin.

[0052] 2. Preparation method

[0053] Mix the above raw materials evenly, pour them into the mold, put them into a 170°C, 10MPa plate press, heat them for 63 minutes, cool to room temperature, take them out, then place the embryo body in a dry oven at 95°C to expand to about 5 to 6 times, and then Transfer to a saturated steam oven at 96±2°C for about 4 hours to reach the desired density, and then solidify in a hot water spray room at 60°C for 6 days to obtain a rigid imide-polyvinyl chloride alloy structural foam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com