Preparation method of foamed nylon plate

A nylon and sheet technology, which is applied in the field of preparation of foamed nylon sheets, can solve problems such as failure to achieve high-efficiency continuous production, and achieve the effects of promoting industrial development, excellent performance and good processing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

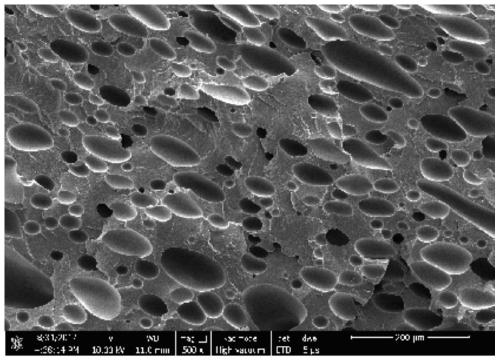

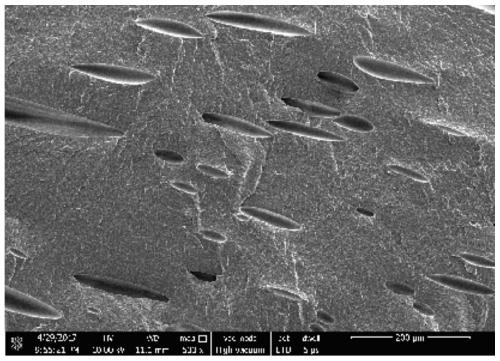

Image

Examples

Embodiment 1

[0034] Get each material of following weight percent: 92 parts by weight of PA6 (M2500), the toughening agent that is 5 parts by weight, the chemical foaming agent that is 1 part by weight, the nucleating agent of 1 part by weight , 0.5 parts by weight of lubricant, 0.3 parts by weight of crosslinking agent, etc., are added to the mixer for pre-mixing and stirring in sequence, the mixing temperature is 30°C, the speed of the mixer is 500r / min, and the mixing time is 3 minutes;

[0035] Put the pre-mixed materials into the stretching rheological plasticizing extrusion equipment, and set the processing temperature of each section of the stretching rheological plasticizing extrusion equipment at 210°C for the first section, 225°C for the second section, and 230°C for the third section , the fourth section 230°C, the fifth section 240°C, the sixth section 235°C, the temperature of the connecting section 220°C, the temperature of the die head 1 zone 220°C, the temperature of the die...

Embodiment 2

[0037] Get each material of following percentage by weight: 89 parts by weight of PA6 (M2500), the toughening agent of 8 parts by weight, the chemical foaming agent of 1.5 parts by weight, the nucleating agent of 1 part by weight, weight 0.5 parts of lubricant, 0.3 parts by weight of crosslinking agent, etc., are added to the mixer for pre-mixing and stirring in sequence. The mixing temperature is 30°C, the speed of the mixer is 500r / min, and the mixing time is 3 minutes;

[0038]Put the pre-mixed materials into the stretching rheological plasticizing extrusion equipment, and set the processing temperature of each section of the stretching rheological plasticizing extrusion equipment at 210°C for the first section, 225°C for the second section, and 230°C for the third section , the fourth section 230°C, the fifth section 240°C, the sixth section 235°C, the temperature of the connecting section 220°C, the temperature of the die head 1 zone 220°C, the temperature of the die head ...

Embodiment 3

[0040] Get each material of following percentage by weight: 91 parts by weight of PA6 (YH800), the toughening agent of 6 parts by weight, the chemical foaming agent of 1 part by weight, the nucleating agent of 1 part by weight, weight 0.5 parts of lubricant, 0.3 parts by weight of crosslinking agent, etc., are added to the mixer for pre-mixing and stirring in sequence. The mixing temperature is 30°C, the speed of the mixer is 500r / min, and the mixing time is 3 minutes;

[0041] Put the pre-mixed materials into the stretching rheological plasticizing extrusion equipment, and set the processing temperature of each section of the stretching rheological plasticizing extrusion equipment at 210°C for the first section, 225°C for the second section, and 230°C for the third section , the fourth section 230°C, the fifth section 240°C, the sixth section 235°C, the temperature of the connecting section 220°C, the temperature of the die head 1 zone 220°C, the temperature of the die head 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com