Halogen-free flame retardant polyphenylene oxide polyphenyl ether (PPE) cable material composition and preparation method thereof

A cable material and composition technology, applied in the field of polymer processing and modification, can solve the problems of low mechanical properties and low mechanical strength of blends, and achieve excellent mechanical properties, high flame retardancy and high resilience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

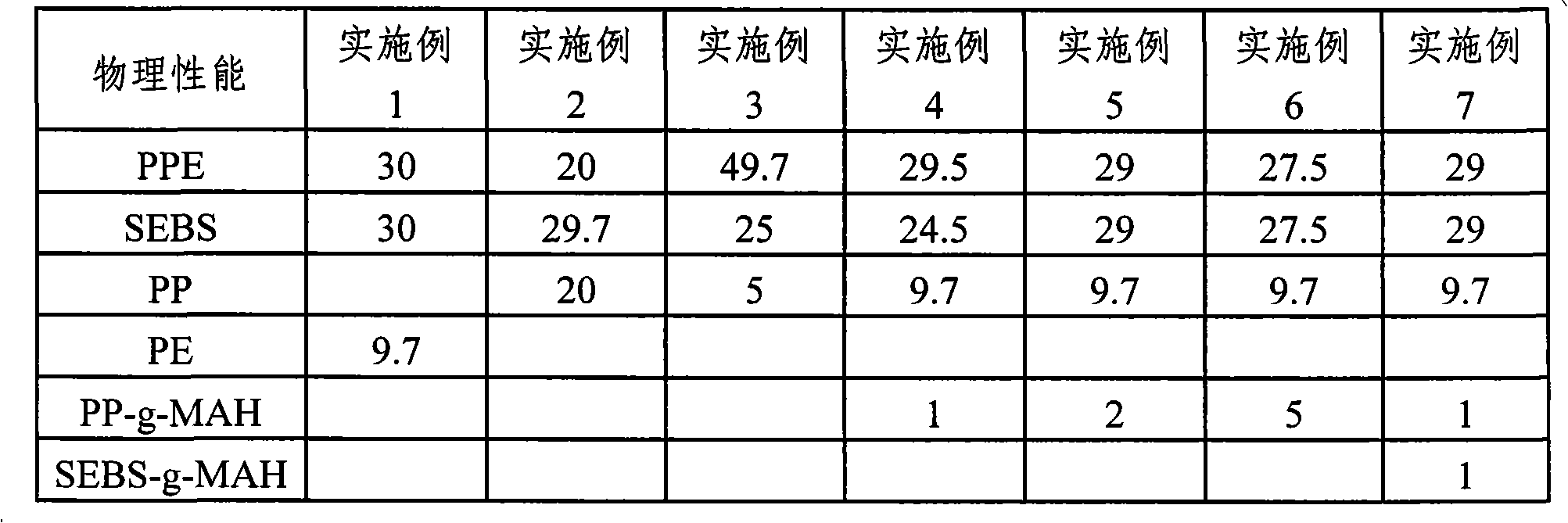

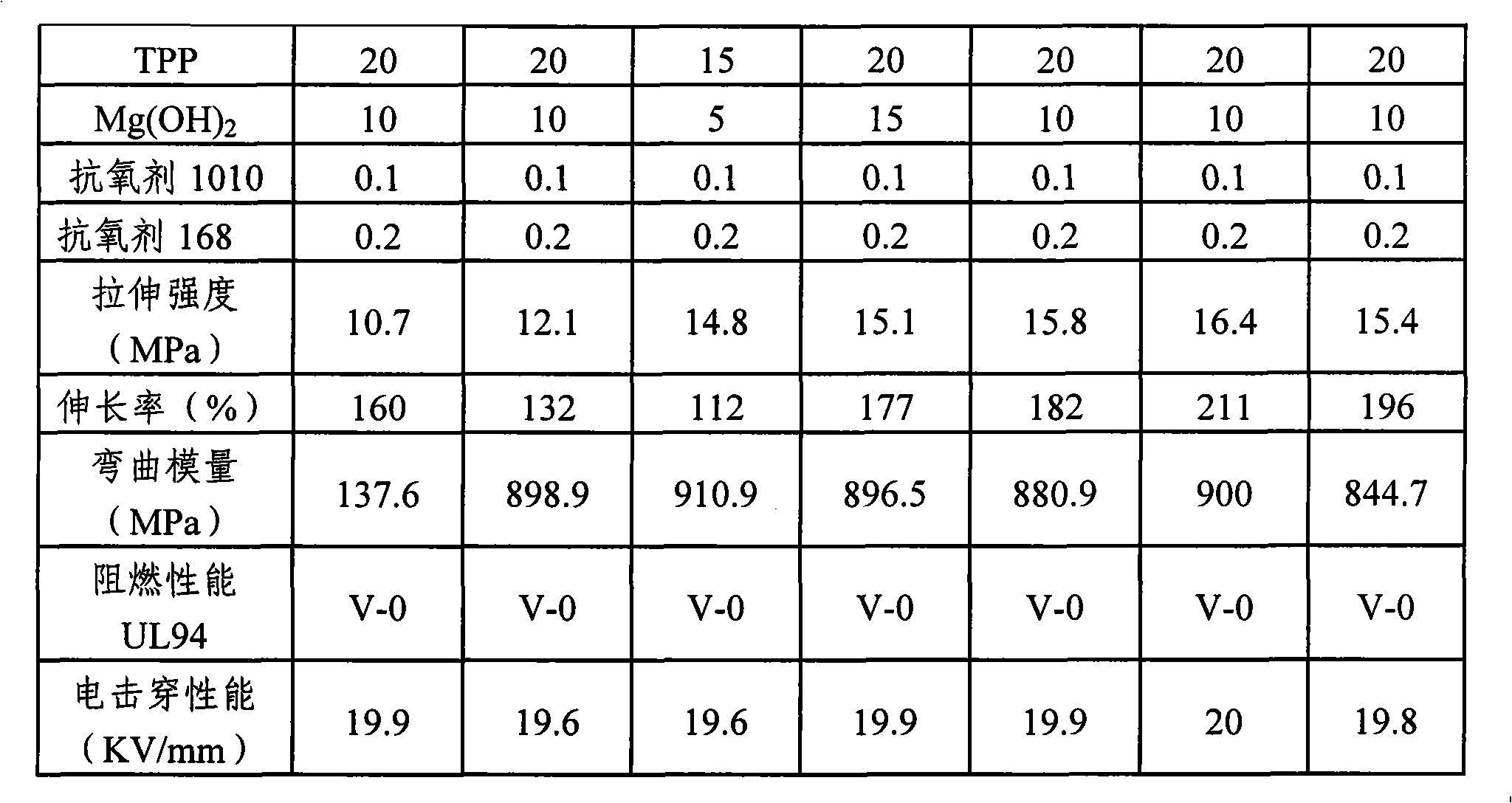

Embodiment 1

[0041] composition:

[0042] Composition Mass (g) Mass percent (%)

[0043] PPE resin 30 30

[0044] SEBS elastomer 30 30

[0045] PE resin 9.7 9.7

[0046]TPP 20 20

[0047] Mg(OH) 2 10 10

[0048] Antioxidant 1010 0.1 0.1

[0049] Antioxidant 168 0.2 0.2

[0050] Weigh the substances according to the above quality, PPE resin, SEBS elastomer, PE resin, TPP, Mg(OH) 2 , Antioxidant 1010 and Antioxidant 168 were sequentially added into the mixer for pre-mixing, the mixing temperature was 20°C, the speed of the mixer was 100 rpm, and the mixing time was 5 minutes.

[0051] The pre-mixed material is fed into a twin-screw extruder for extrusion granulation. During extrusion, the processing temperature of each section of the twin-screw extruder is set to 220°C for the first section, 240°C for the second section, 260°C for the third section, 260°C for the fourth section, 260°C for the fifth section, and 260°C for the sixth section. , The seventh section is 260°C, the e...

Embodiment 2

[0054] composition:

[0055] Composition Mass (g) Mass percent (%)

[0056] PPE resin 20 20

[0057] SEBS elastomer 29.7 29.7

[0058] PP resin 20 20

[0059] TPP 20 20

[0060] Mg(OH) 2 10 10

[0061] Antioxidant 1010 0.1 0.1

[0062] Antioxidant 168 0.2 0.2

[0063] Weigh the substances according to the above quality, PPE resin, SEBS elastomer, PP resin, TPP, Mg(OH) 2 , Antioxidant 1010 and Antioxidant 168 were sequentially added into the mixer for pre-mixing, the mixing temperature was 20°C, the speed of the mixer was 100 rpm, and the mixing time was 5 minutes.

[0064] The pre-mixed material is fed into a twin-screw extruder for extrusion granulation. During extrusion, the processing temperature of each section of the twin-screw extruder is set to 220°C for the first section, 240°C for the second section, 260°C for the third section, 260°C for the fourth section, 260°C for the fifth section, and 260°C for the sixth section. , The seventh section is 260°C, th...

Embodiment 3

[0067] composition:

[0068] Composition Mass (g) Mass percent (%)

[0069] PPE resin 49.7 49.7

[0070] SEBS elastomer 25 25

[0071] PP resin 5 5

[0072] TPP 15 15

[0073] Mg(OH) 2 5 5

[0074] Antioxidant 1010 0.1 0.1

[0075] Antioxidant 168 0.2 0.2

[0076] Weigh the substances according to the above quality, PPE resin, SEBS elastomer, PP resin, TPP, Mg(OH) 2 , Antioxidant 1010 and Antioxidant 168 Weigh the substances according to the above quality, add them to the mixer for pre-mixing in sequence, the mixing temperature is 20°C, the speed of the mixer is 100 rpm, and the mixing time is 5 minutes.

[0077] The pre-mixed material is fed into a twin-screw extruder for extrusion granulation. During extrusion, the processing temperature of each section of the twin-screw extruder is set to 220°C for the first section, 240°C for the second section, 260°C for the third section, 260°C for the fourth section, 260°C for the fifth section, and 260°C for the sixth sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com