High toughness filling reinforcement poly phenylene sulfide (PPS)/poly-p-phenylene oxide (PPO) alloy and method for preparing same

A high-toughness, alloy technology, applied in the field of high-toughness filled reinforced PPS/PPO alloy and its preparation, can solve the problems of high fluidity, poor impact strength, electrolyte leakage, etc., and achieve stress cracking resistance, excellent strength and Rigidity, the effect of saving equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

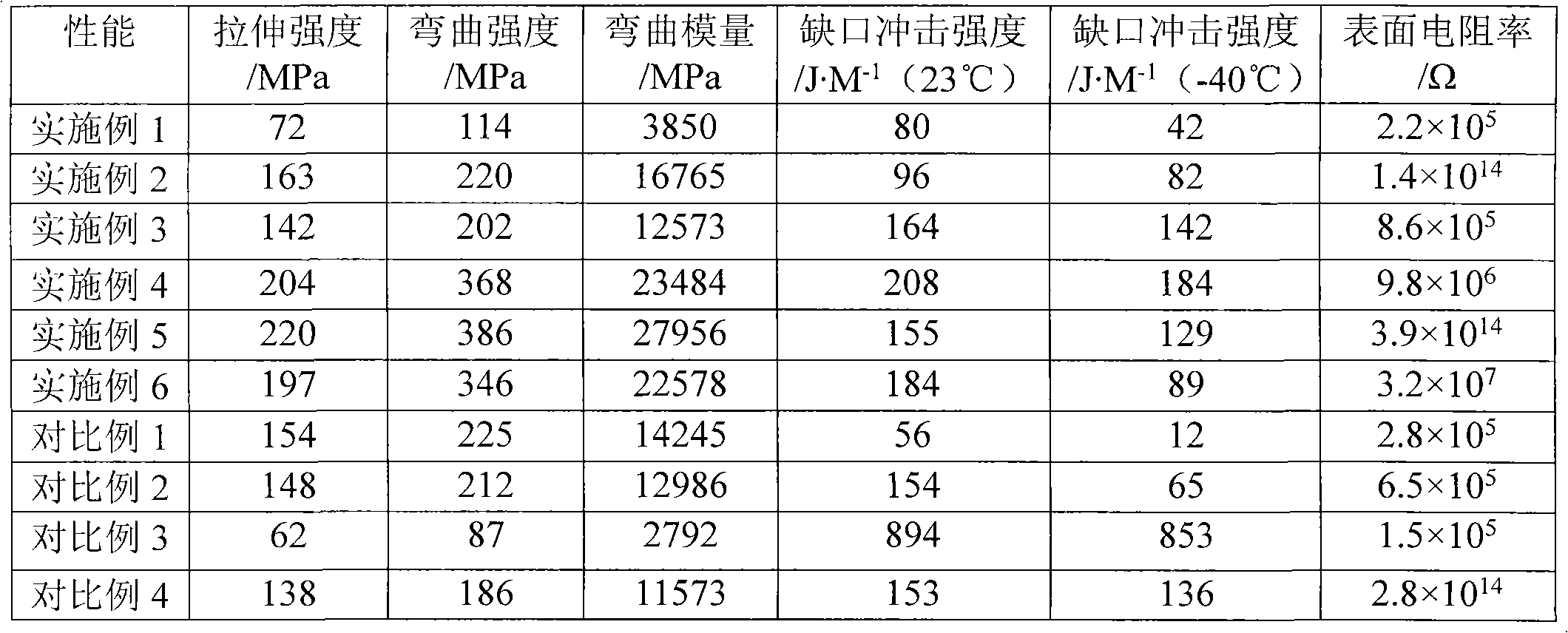

Examples

Embodiment 1:1Kg、99Kg、50Kg、3KgM3002、5KgSEBS(5%)、0.2Kg、0.1KgN412S、0.1KgN445、0.5KgOP-180 to ,10Kg, to 。、、、、、。, and 240~310℃。 Embodiment 2

[0024] Example 1: 1Kg polyphenylene sulfide, 99Kg polyphenylene ether, 50Kg iron powder, 3Kg compatibilizer M3002, 5Kg silicone oil filled SEBS (silicone oil mass fraction is 5%), 0.2Kg aluminate coupling agent, Add 0.1Kg of antioxidant N412S, 0.1Kg of antioxidant N445, and 0.5Kg of OP-180 into a high-speed mixer and mix evenly at high speed, then add 10Kg of chopped glass fiber and mix evenly at a low speed to obtain a mixed material. Then the mixed materials are melted, kneaded, extruded, cooled, dried, pelletized into pellets through a twin-screw extruder and then injected into products. Among them, the temperature of each partition of the twin-screw extruder and the screw barrel of the injection molding machine should be kept between 240 and 310 °C. Example 2: SEB-g-MAH filled with 99Kg polyphenylene sulfide, 1Kg polyphenylene ether, 1Kg silicon carbide, 10KgHIPS, 30Kg fluorine oil (the mass fraction of fluorine oil is 50%), 2Kg titanate coupling agent Add NDZ-101, 1Kg an...

Embodiment 3

[0025] Example 3: 60Kg polyphenylene sulfide, 40Kg polyphenylene ether, 30Kg graphite, 4KgPPO-g-MAH, 20Kg silicone oil filled SEBS-g-MAH (silicone oil mass fraction is 25%), 2Kg aluminate coupling Agent, 0.4Kg N412S, 0.4Kg antioxidant N445, 1Kg stearic acid, 0.5Kg light stabilizer were added to the high-speed mixer and mixed evenly at high speed, and then 80Kg chopped glass fiber was added and mixed evenly at low speed to obtain a mixed material. Then the mixed materials are melted, kneaded, extruded, cooled, dried, pelletized into pellets through a twin-screw extruder and then injected into products. Among them, the temperature of each partition of the twin-screw extruder and the screw barrel of the injection molding machine should be kept between 240 and 310 °C.

Embodiment 4:70Kg、30Kg、20Kg、6Kg、25Kg、1KgKH550、0.6KgN412S、0.6KgN445、1Kg and 1 ,。,100Kg,、260~340℃、 and , to PPS/PPO(11~25mm)。 Embodiment 5

[0026] Example 4: 70Kg polyphenylene sulfide, 30Kg polyphenylene ether, 20Kg carbon nanotubes, 6Kg epoxy resin, 25Kg silicone modified acrylic resin, 1Kg silane coupling agent KH550, 0.6Kg antioxidant N412S, 0.6Kg Antioxidant N445, 1Kg silicone powder and an appropriate amount of absolute ethanol are stirred together under a homogenizer to form a uniformly dispersed suspension. Pour the suspension into an impregnation device, draw 100Kg of glass fiber yarn through the suspension continuously, dry to remove ethanol, heat and melt at 260-340°C, cool and pelletize to obtain high-toughness long glass fiber reinforced PPS / PPO alloy (granule length 11-25mm). Example 5: 80Kg polyphenylene sulfide, 20Kg polyphenylene ether, 10Kg alumina, 5Kg ethylene-glycidyl methacrylate copolymer, 15Kg carboxyl silicone resin, 0.8Kg silane coupling agent N-β-aminoethyl Base-γ-aminopropylmethyldimethoxysilane, 0.8Kg antioxidant N412S, 0.8Kg antioxidant N445, 0.5Kg silicone powder, 0.5Kg light stabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com