Thermoplastic resin composition, molded product, and method of producing molded product

A thermoplastic resin, manufacturing method technology, applied in household components, applications, household appliances, etc., can solve the problems of heat resistance, flame retardancy, dimensional stability, low mechanical strength, etc., achieve excellent heat resistance, good appearance, The effect of satisfying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0229] Hereinafter, although an Example and a comparative example are used and this invention is demonstrated more concretely, this invention is not limited to an Example etc. at all.

[0230] First, the raw materials of the thermoplastic resin compositions used in Examples and Comparative Examples will be described below.

[0231] (A) Polyamide (PA)

[0232] Poly(hexamethylene adipamide) (PA66) (viscosity value = 120mL / g, terminal amino group concentration = 30μmol / g, terminal carboxyl group concentration = 110μmol / g, when PA66 is polymerized, it is polymerized under the coexistence of copper iodide and potassium iodide , containing 100 mass ppm of copper and 4000 mass ppm of iodine in PA66.)

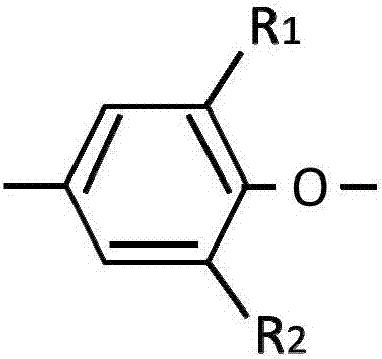

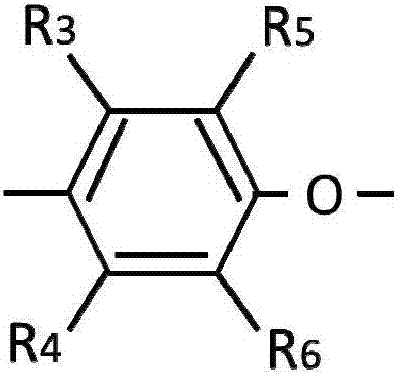

[0233] (B) Polyphenylene ether (PPE)

[0234] Poly(2,6-dimethyl-1,4-phenylene ether) (reduced viscosity=0.42dL / g (0.5g / dL chloroform solution, 30°C, measured by Ubbelohde viscosity tube))

[0235] (C) Compatibilizer

[0236] MAH (trade name "maleic anhydride", manufactured by Mitsu...

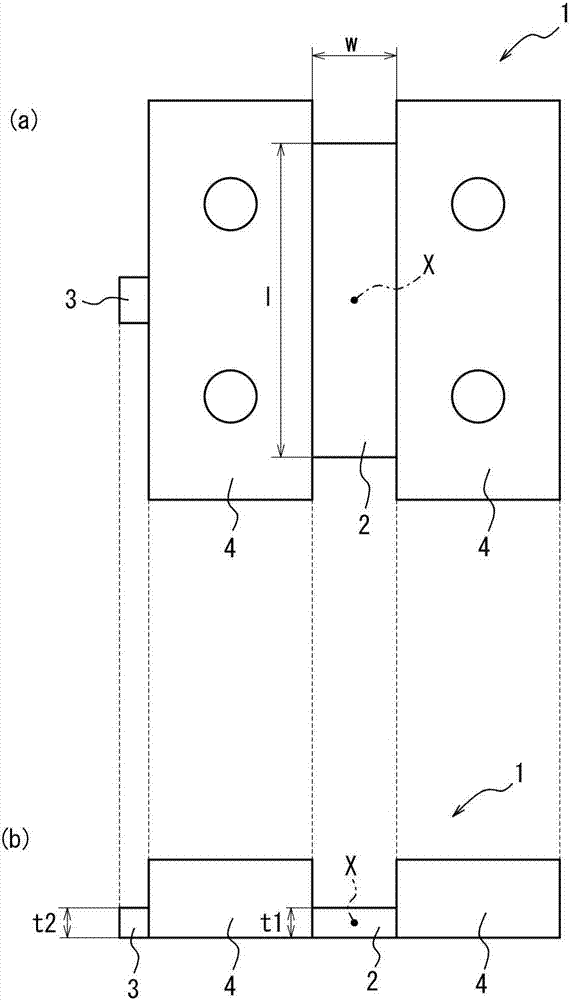

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com