Nano graphene platelet-based conductive inks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Nano-Scaled Graphene Platelets (NGPs) from Natural Graphite Flakes

[0051]A typical procedure for preparing non-oxidized NGP-based conductive inks is described as follows: Five grams of graphite flakes, ground to approximately 10 μm or less in sizes, were dispersed in 1,000 mL of deionized water (containing 0.1% by weight of a dispersing agent, Zonyl® FSO surfactant from DuPont) to obtain a suspension. An ultrasonic energy level of 95 W (Branson S450 Ultrasonicator) was used for exfoliation, separation, and size reduction for different periods of time: 0.5, 1, 2, and 3 hours. The average thickness of the NGPs prepared was found to be 33 nm, 7.4 nm, 1 nm, and 0.89 nm, respectively.

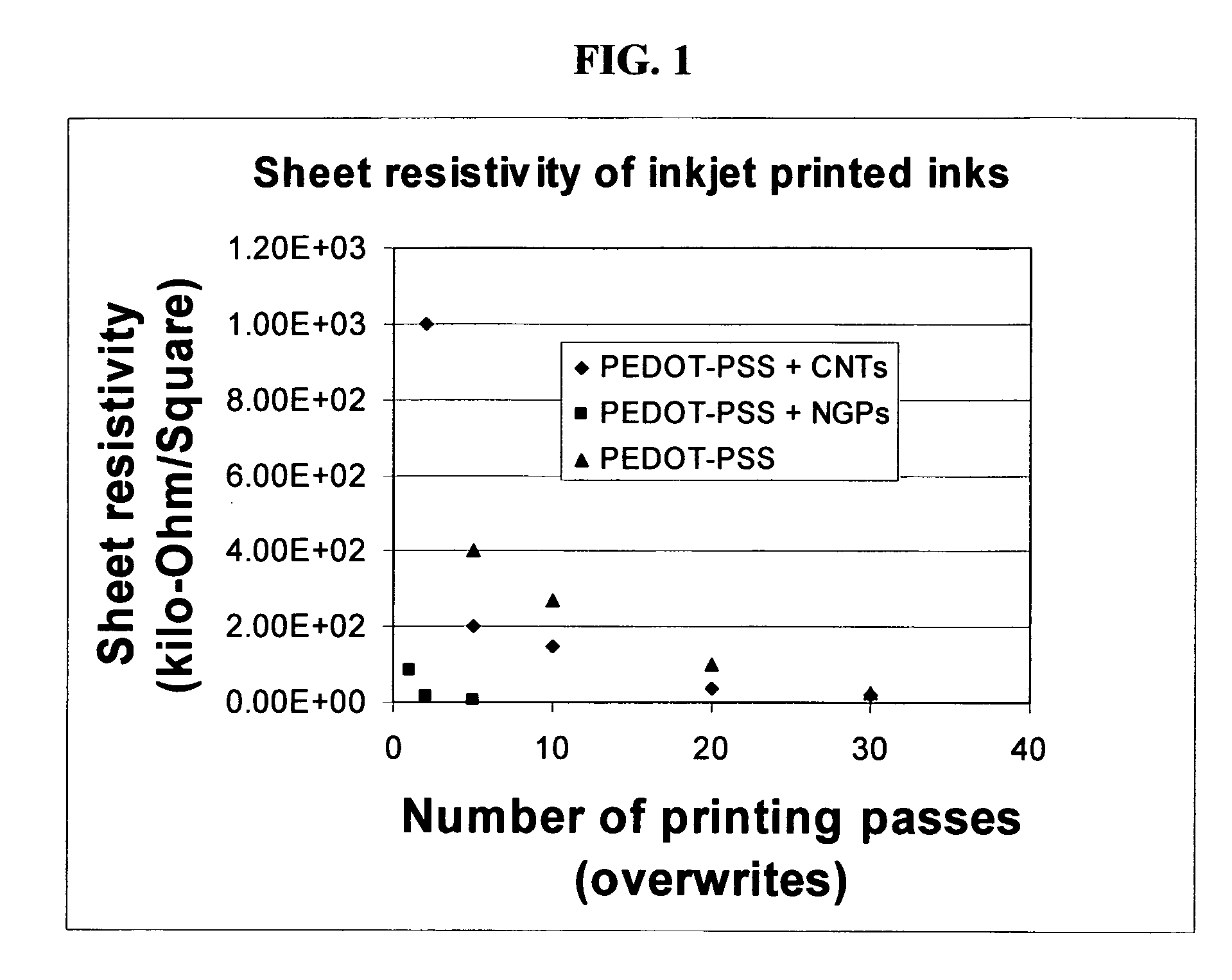

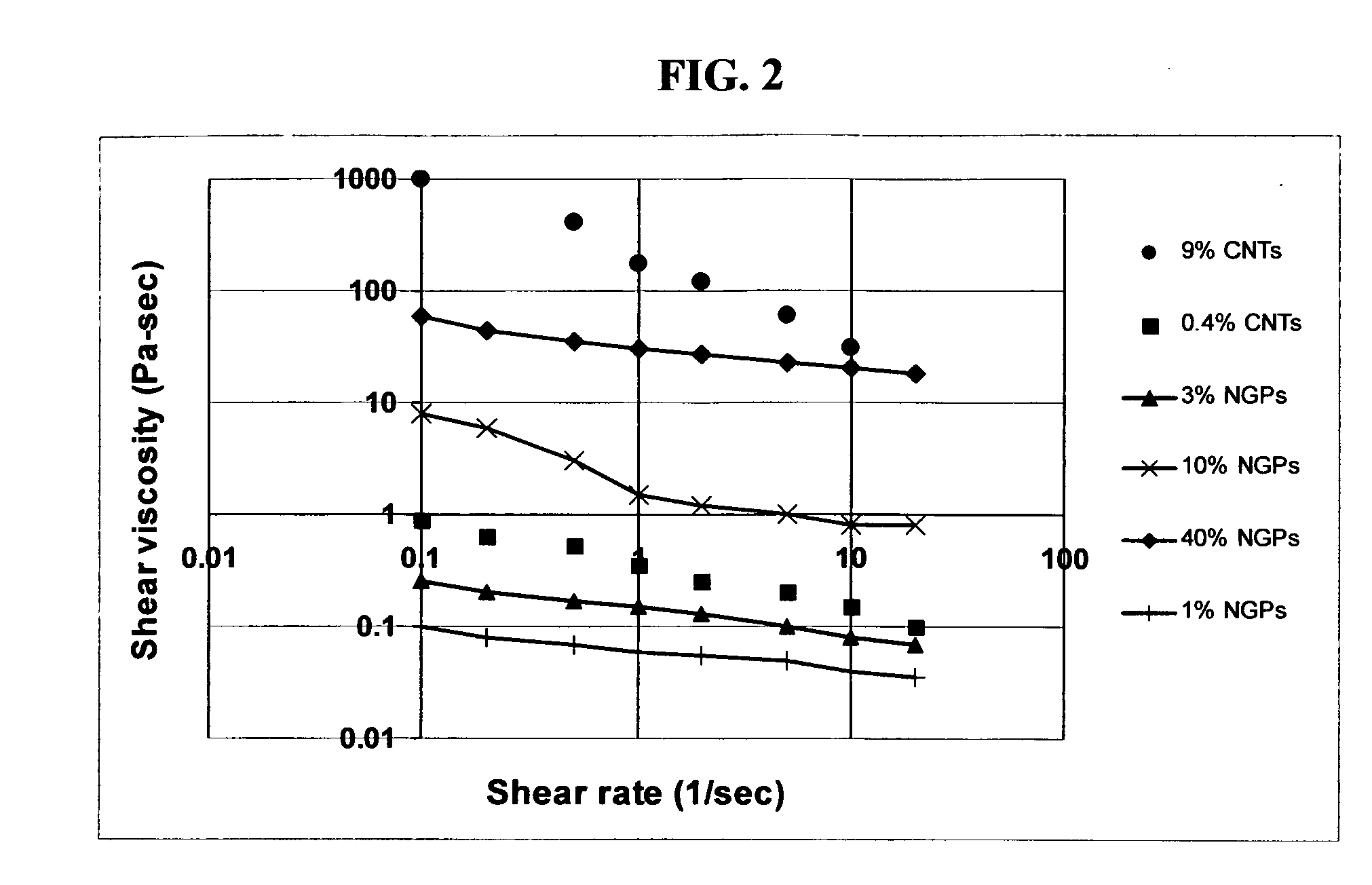

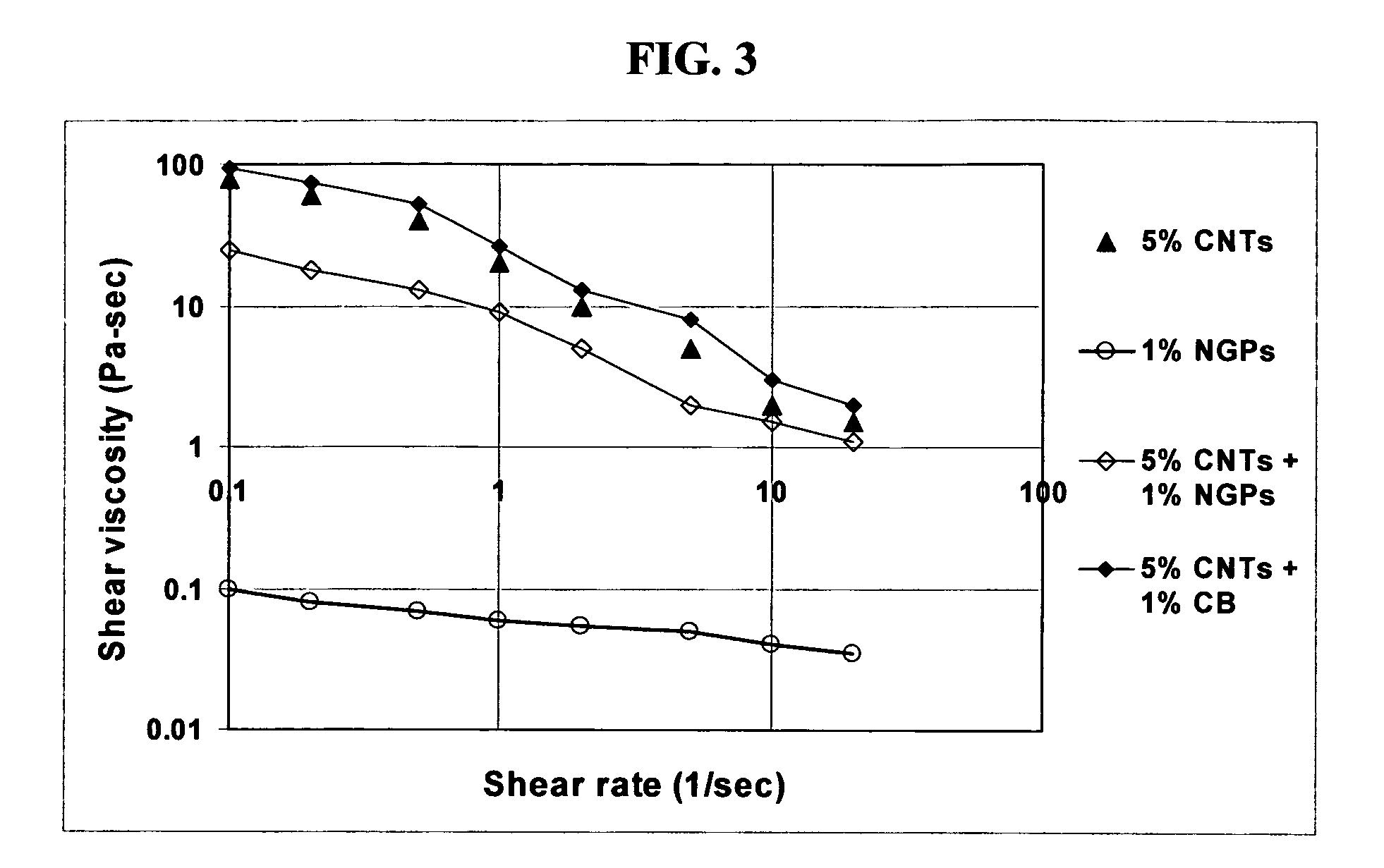

[0052]For ink viscosity studies, the NGPs used were those with an average thickness of 7.4 nm. The water content of an ink sample was adjusted by using controlled evaporation (to increase NGP volume fraction in a suspension) or adding water (to dilute it). Suspensions with a range of NGP volume fractions, up ...

example 2

Nano-Scaled Graphene Platelets (NGPs) from Natural Graphite Flakes (No Dispersing Agent)

[0053]Five grams of graphite flakes, ground to approximately 10 μM or less in sizes, were dispersed in 1,000 mL of deionized water to obtain a suspension. An ultrasonic energy level of 95 W (Branson S450 Ultrasonicator) was used for exfoliation, separation, and size reduction for a period of 2.5 hours. The resulting NGPs, although thicker than those prepared with the assistance of a surfactant, were also well dispersed in water, forming a surfactant-free ink.

example 3

Preparation of Inks Containing Oxidized NGPs (Graphite Oxide Platelets)

[0054]Graphite oxide was prepared by oxidation of graphite flakes with sulfuric acid, nitrate, and potassium permanganate, at a ratio of 4: 1:0.01 at 30° C., according to the method of Hummers [U.S. Pat. No. 2,798,878, Jul. 9, 1957]. Upon completion of the reaction, the mixture was poured into deionized water and filtered. The sample was then washed with 5% HCl solution to remove most of the sulfate ions and residual salt and then repeatedly rinsed with deionized water until the pH of the filtrate was approximately 7. The intent was to remove all sulfuric and nitric acid residue out of graphite interstices. The slurry was spray-dried and stored in a vacuum oven at 60° C. for 24 hours. The interlayer spacing of the resulting laminar graphite oxide was determined by the Debye-Scherrer X-ray technique to be approximately 0.73 nm (7.3 Å), indicating that graphite has been converted into graphite oxide. Graphite oxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com