Thread baking thread process control method

A process control and drying technology, which is applied in the field of tobacco production, can solve the problems of large delay in control and response, large dry tobacco, and large disturbance in the drying process, and achieves the effects of high control accuracy and strong anti-interference ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

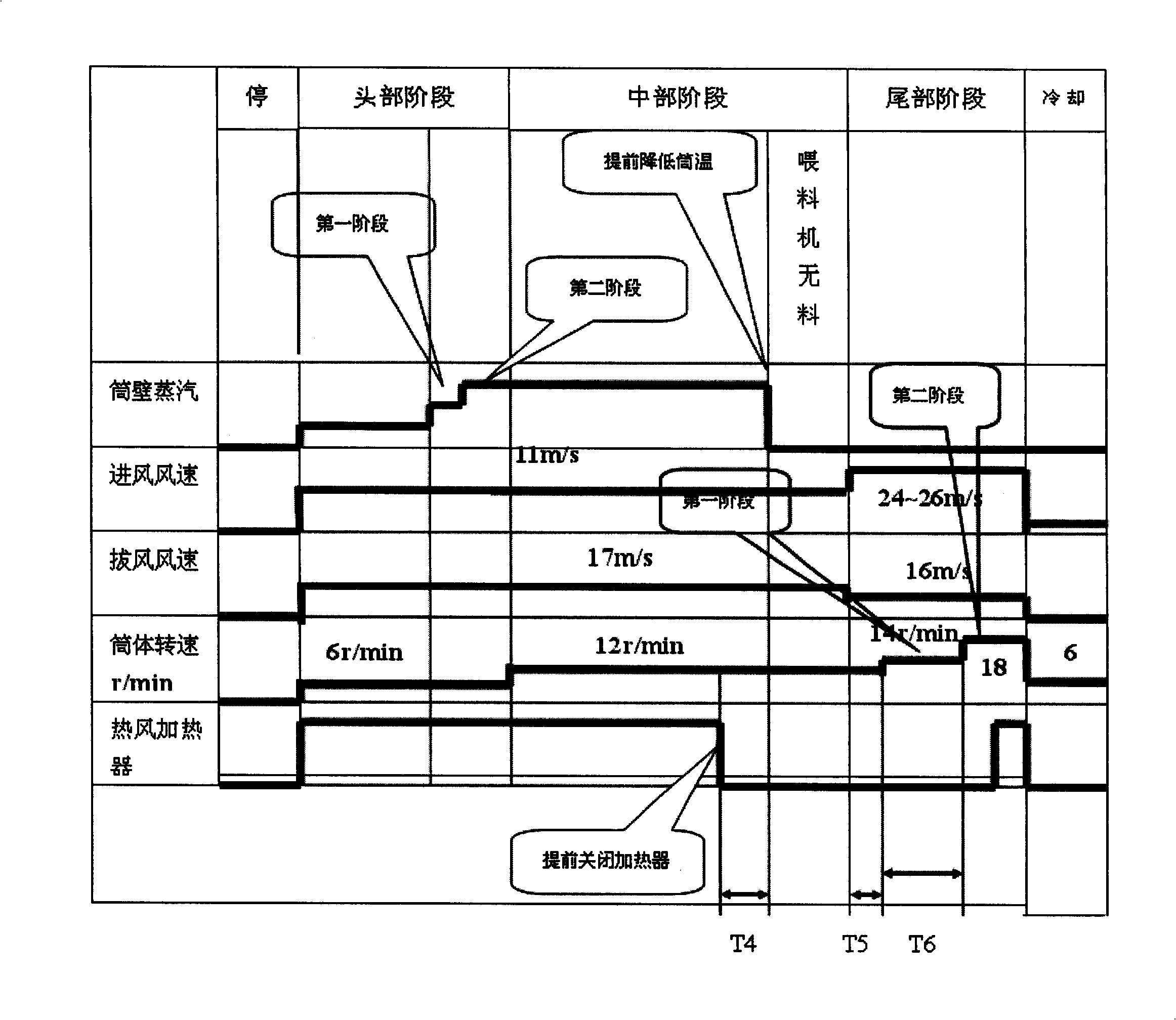

[0016] A silk drying process control method, the characteristics of this patent are described from the three aspects of control model, hardware configuration and control mode.

[0017] 1. Control Model

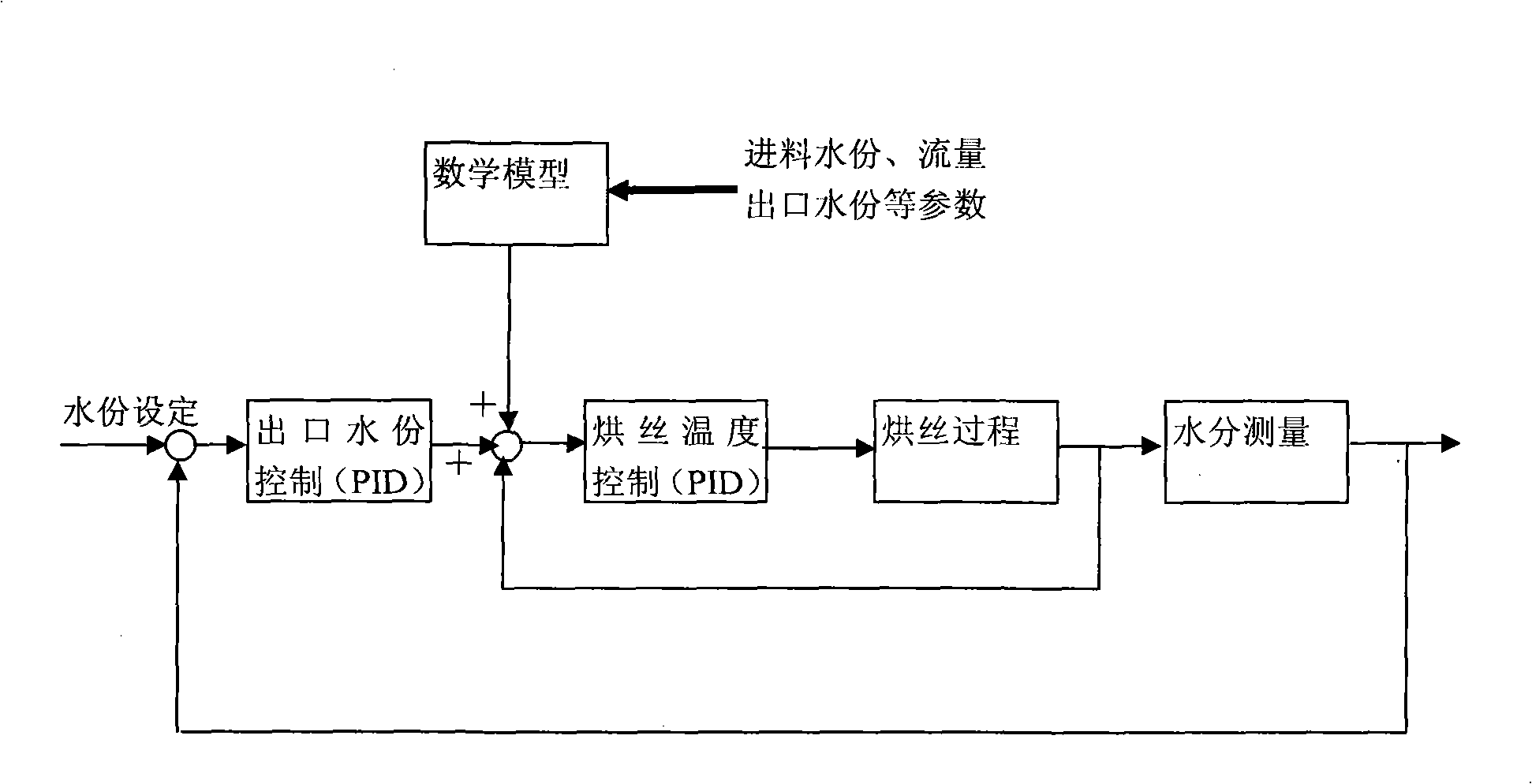

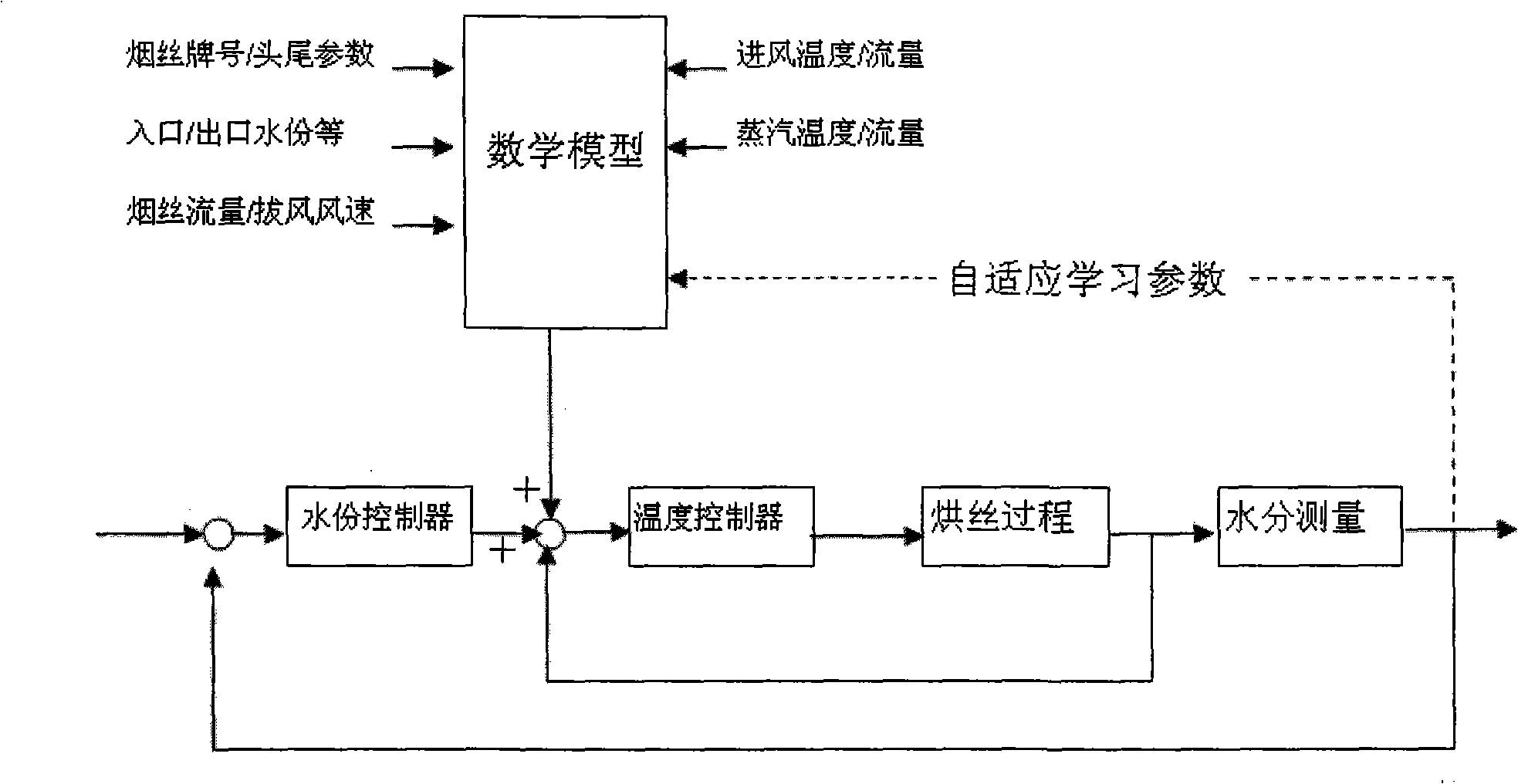

[0018] A new control method using self-learning technology combined with predictive PID technology, the control block diagram is as follows figure 2 shown.

[0019] The new control model overcomes the influence of non-linearity and large lag in the control process of the original silk drying process on the moisture at the outlet of the dried silk, so that the control system has strong anti-interference ability and can adapt to changes in various working conditions, so that the moisture at the outlet of the dried silk can be effectively reduced. The control achieves high control precision.

[0020] 2. Hardware configuration

[0021] In terms of hard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com