Drum washing-drying machine and drying time determining method

A technology for washing and drying machines and drying time, which is applied to washing machines with containers, household dryers, washing devices, etc., can solve the problems of low reliability, complicated processing procedures, and increased costs, and achieves high accuracy. , to achieve automatic control, solve the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

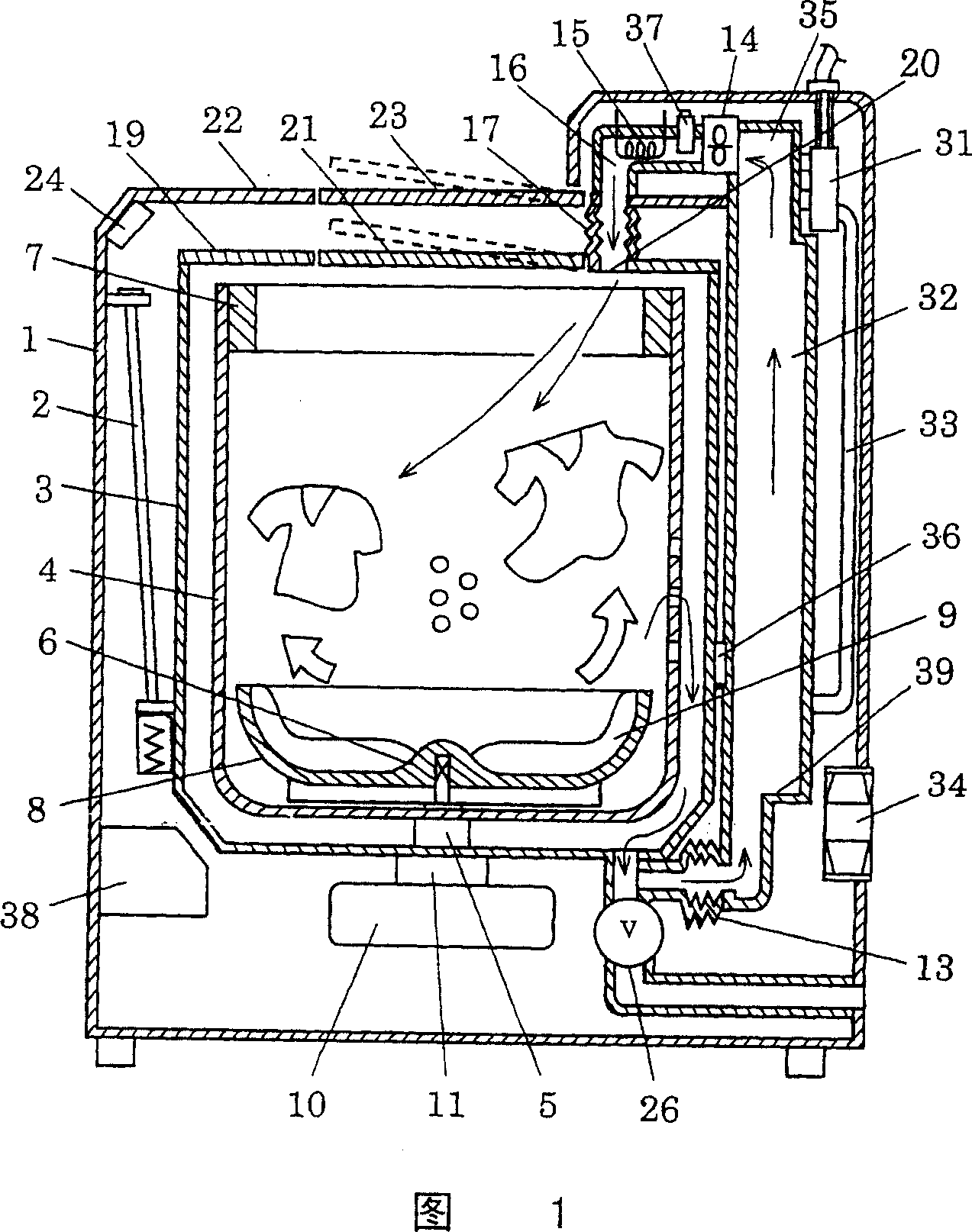

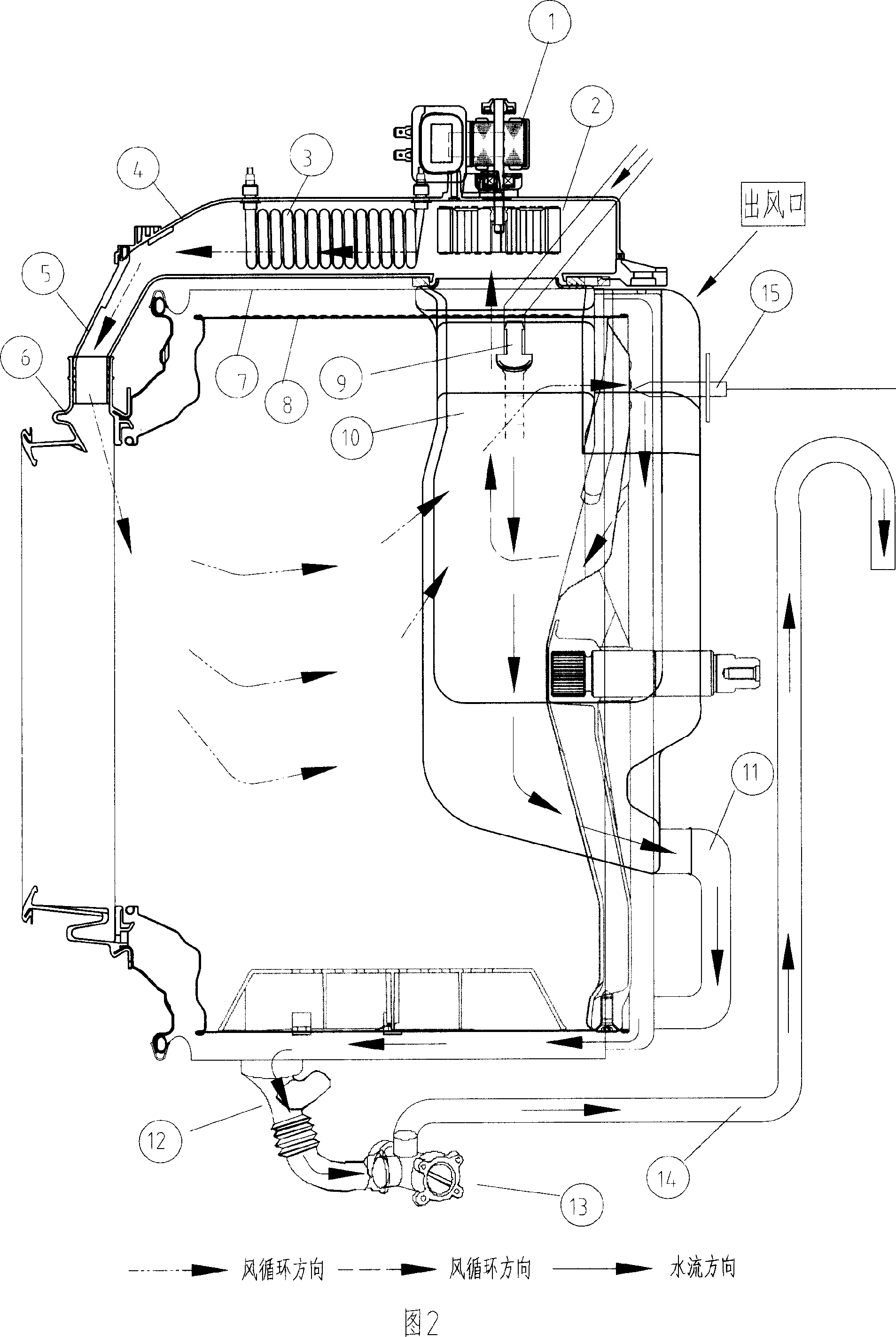

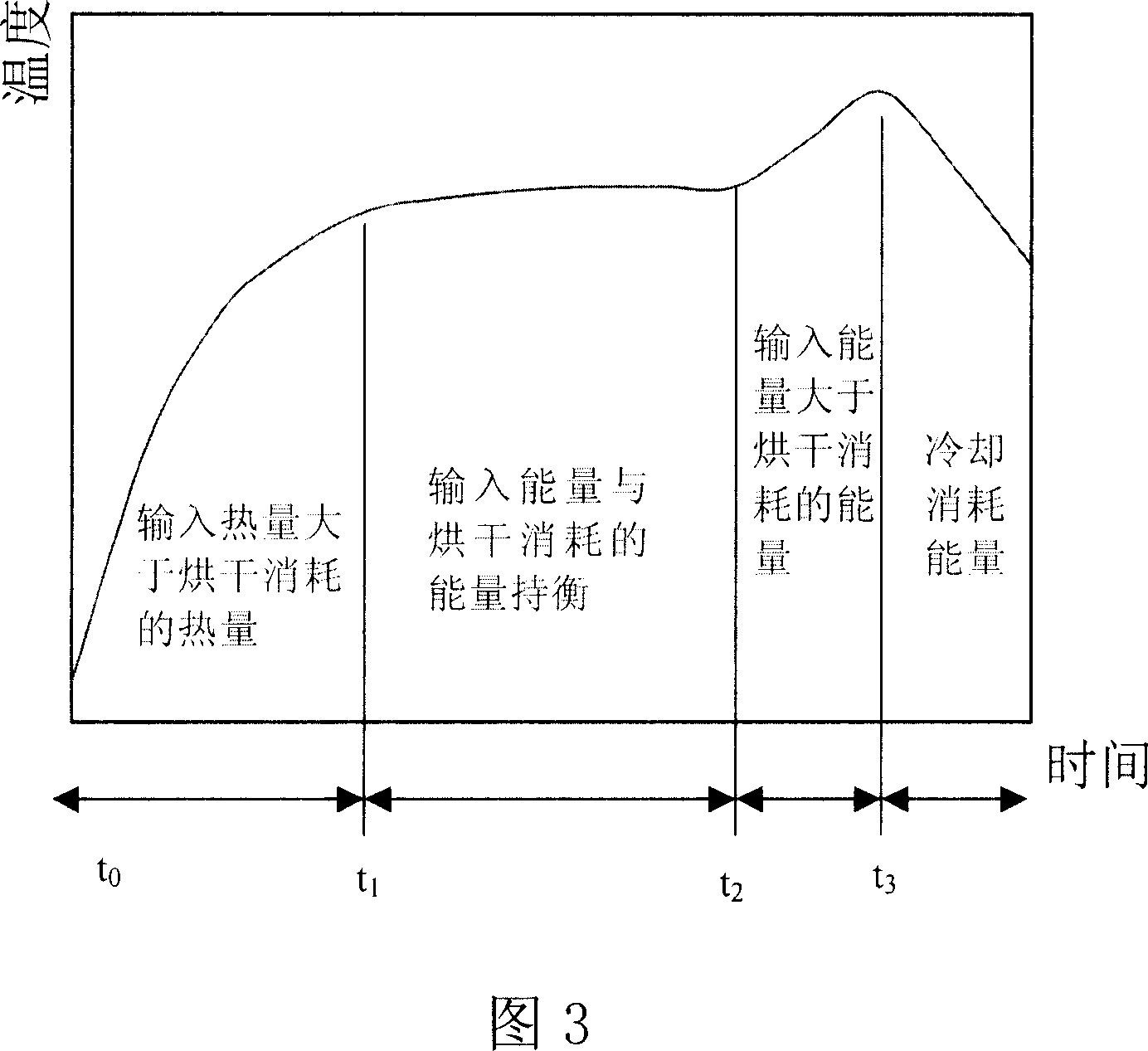

[0040] The present invention provides a drum-type washing and drying machine and a method for determining the drying time by using only one thermometer to determine the inflection point A and defining the inflection point A accordingly. Fig. 2 is a schematic structural view of the drum type washing and drying machine provided by the present invention. As shown in the figure, the drum type washing and drying machine of the present invention includes: an outer cylinder 41 arranged in the casing; a drum 42 is rotatably arranged in the outer cylinder 41, and the drum 42 is used for Put the laundry and rotate it in the outer cylinder driven by the motor to achieve the purpose of washing; there is an observation window 43 in front of the casing for observing the rolling washing of the drum and clothes; a drainage system 44 is connected to the bottom of the outer cylinder 41 The drain port 45 is used to discharge the washing water and the condensed water in the drying process; a dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com