Environment-friendly polluted waste purification treatment device and system

A purification treatment and environmental protection technology, applied in the field of environmental purification treatment, can solve the problems of poor treatment effect, pollution of the ocean, high mechanical properties of sludge and soil, etc., and achieve the effect of easy direct use and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] The following examples are only used to illustrate the technical solution of the present invention more clearly, so they are only examples, and should not be used to limit the protection scope of the present invention.

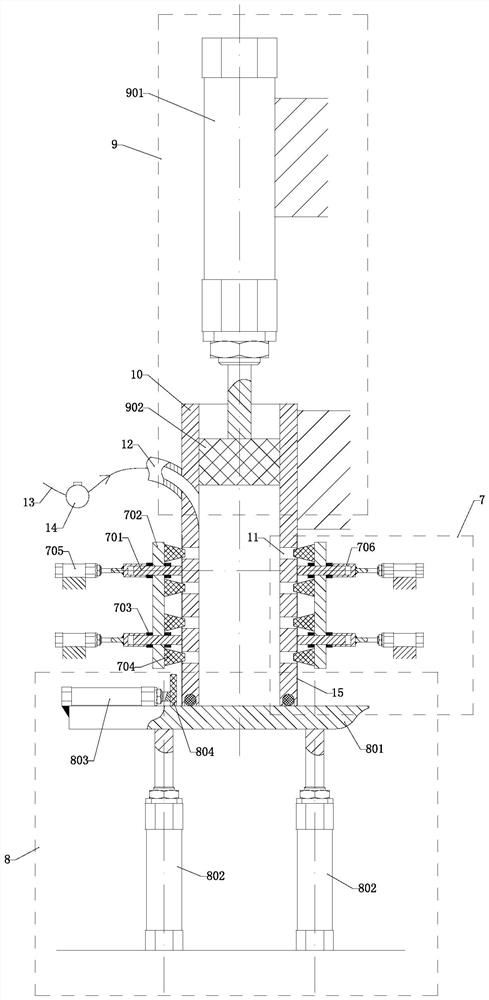

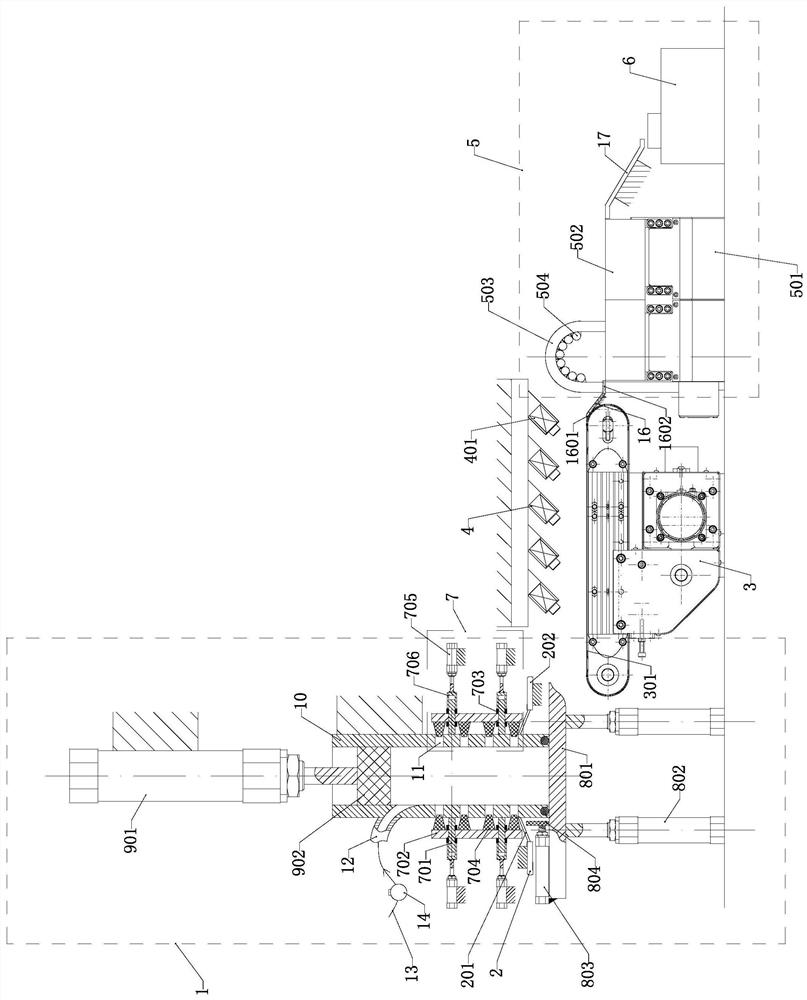

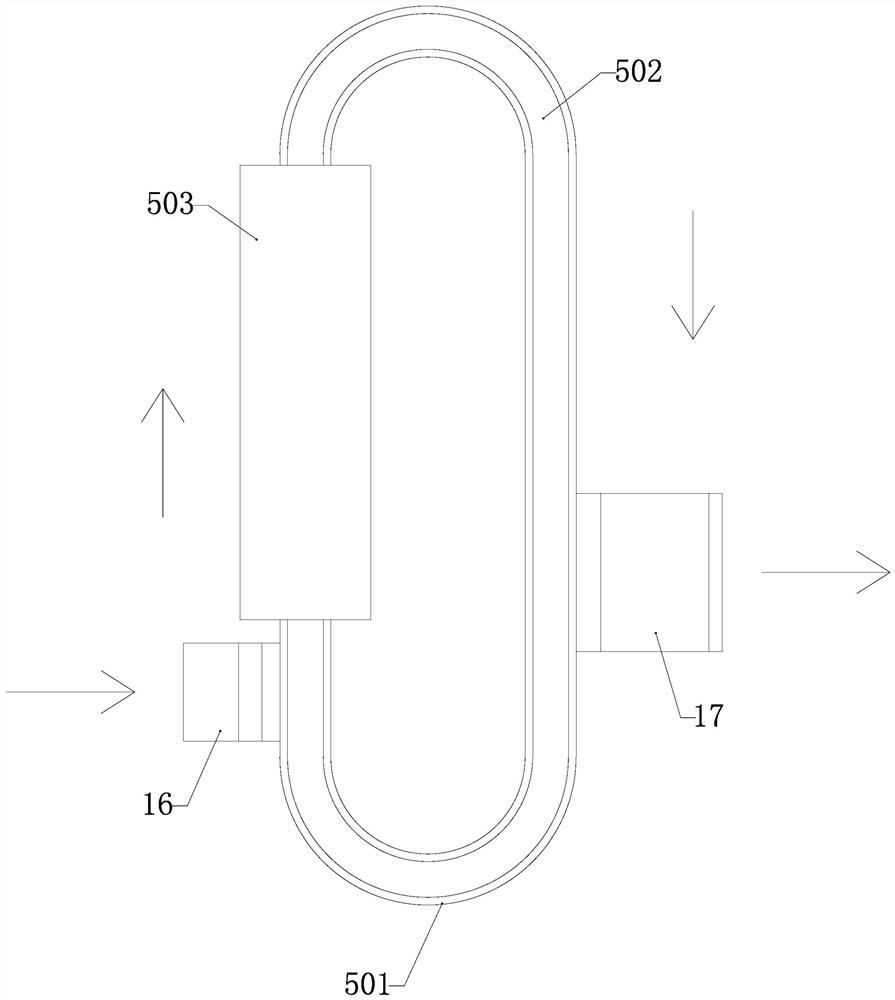

[0032] like Figure 1-4As shown in , the environment-friendly polluted waste purification treatment device includes a vertical alloy steel cylinder 10 that is vertically connected up and down. The alloy steel cylinder 10 is fixedly arranged relative to the ground, and the peripheral shape of the cross section of the alloy steel cylinder 10 is The cross-sectional shape of the inner cavity is square, and the shape of the inner cavity is circular. On the two opposite outer walls of the lower section of the alloy steel cylinder 10, there are respectively symmetrically arranged several pressurized drainage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com