Downhole steam secondary electric heating pipe column and heating method

A heating method and secondary electric technology, applied in the shape of heating elements, earthwork drilling, wellbore/well parts, etc., to achieve the effect of improving steam sweeping effect, improving dryness, and improving steam throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

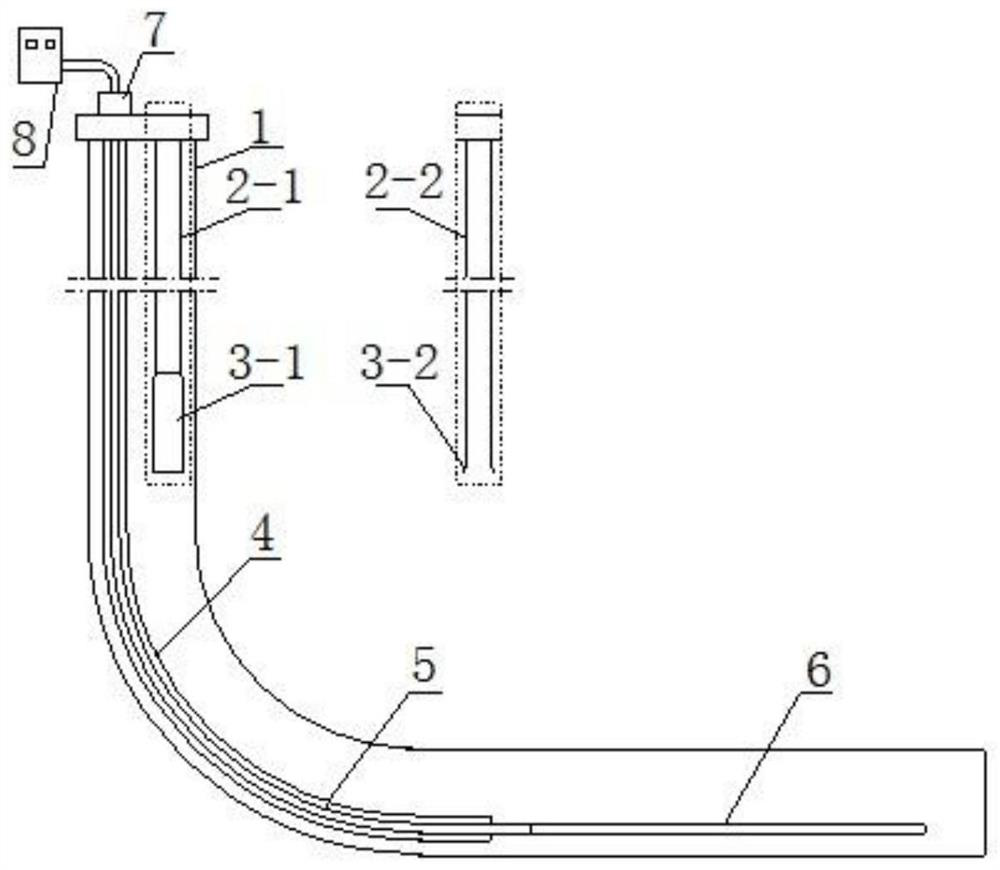

[0029] The overall design idea of the present invention: in order to improve the dryness of downhole steam, consider using the surface boiler to heat the steam once and then reheat the steam reaching the bottom of the well twice. For deep wells with steam flooding and SAGD depths of 1000-2000 meters, this This method can effectively improve the dryness of downhole steam. In the present invention, the coiled tubing 5 and the electric heater 6 are lowered into the steam wellhead, and the bottom electric heater 6 reheats the low-quality steam at the bottom of the well, so that the temperature and pressure of the steam at the bottom of the well are increased, and the dryness is greatly improved. Improvement to facilitate the high-temperature and high-pressure diffusion of steam, improve the steam sweep effect, improve the heating efficiency of steam stimulation, steam flooding, and SAGD, and the dryness index can be increased by 20-30%.

[0030] As for the downhole steam seconda...

Embodiment 2

[0038] The coiled tubing 5 that is used for the method described in embodiment 1:

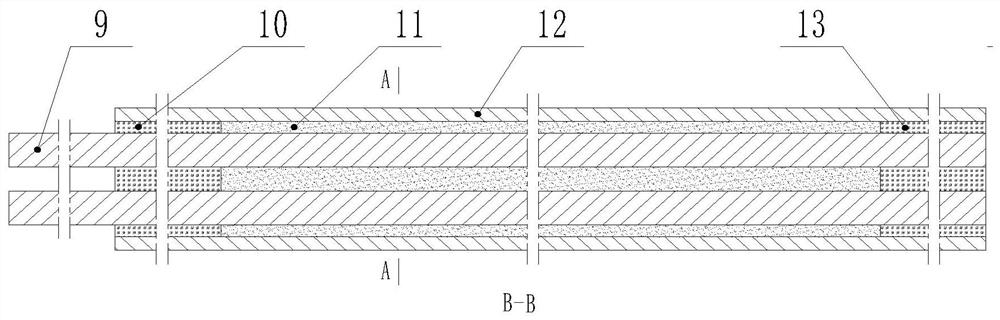

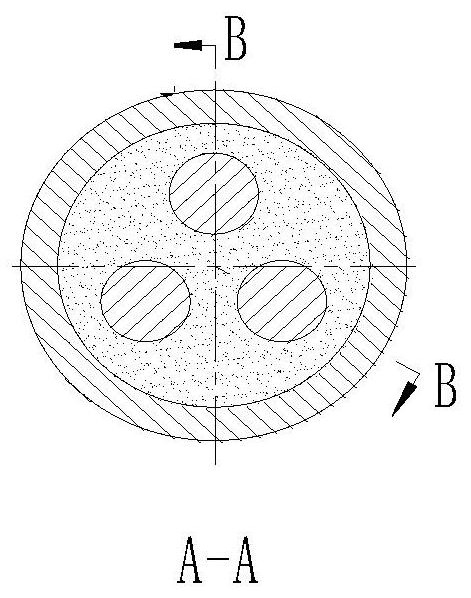

[0039] Including continuous pipe body 12, cable core a9, insulator a11, upper head 10, lower head 13,

[0040] The outer diameter of the continuous pipe body 12 of this embodiment is 25.4mm, and the wall thickness is 2.4mm. It is made of 316L stainless steel, and three cable cores a9 are penetrated in the middle. The insulator a11 is covered between the continuous pipe body 12, and the material of the insulator a11 is magnesium oxide powder, which is used as insulation and can resist high temperature and transfer heat. The upper sealing head 10 and the lower sealing head 13 are installed on both ends of the continuous pipe body 12 respectively, and are used to seal the insulator a11, isolate the insulator a11 from the outside air, and prevent interference from getting wet. Upper sealing head 10, lower sealing head 13 are 10 centimeters long, adopt epoxy resin material. The length of the cable...

Embodiment 3

[0057] The tubing strings described in Example 2 are not only applicable to horizontal well steam injection wells, but also to horizontal well production wells. When used in horizontal well production wells, the heating medium is replaced by oil well production fluid, and the production method adopts Φ114mm tubing 2 -1 and Φ120mm tubular pump 3-1 are used for bottomhole heating to assist oil production.

[0058] When the viscosity of the output fluid in the horizontal well increases and wax is produced, the control cabinet 8 can be used to adjust the power, and the electric heater 6 at the bottom of the well can be energized and heated to realize heating and viscosity reduction, increase the temperature of the output fluid at the outlet of the oil well, and increase the temperature of the horizontal well Yield. When the water content of the produced fluid is large, the well production can be stopped, and the high-power output of the control cabinet 8 can be adjusted to energiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Heat resistant | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com