Method for extracting fragrant liquor and essential oil from aromatic plants by dry-process

A plant extraction and aroma technology, applied in the direction of essential oils/spices, fat production, etc., can solve the problems of high energy consumption, low output, and no enterprise mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

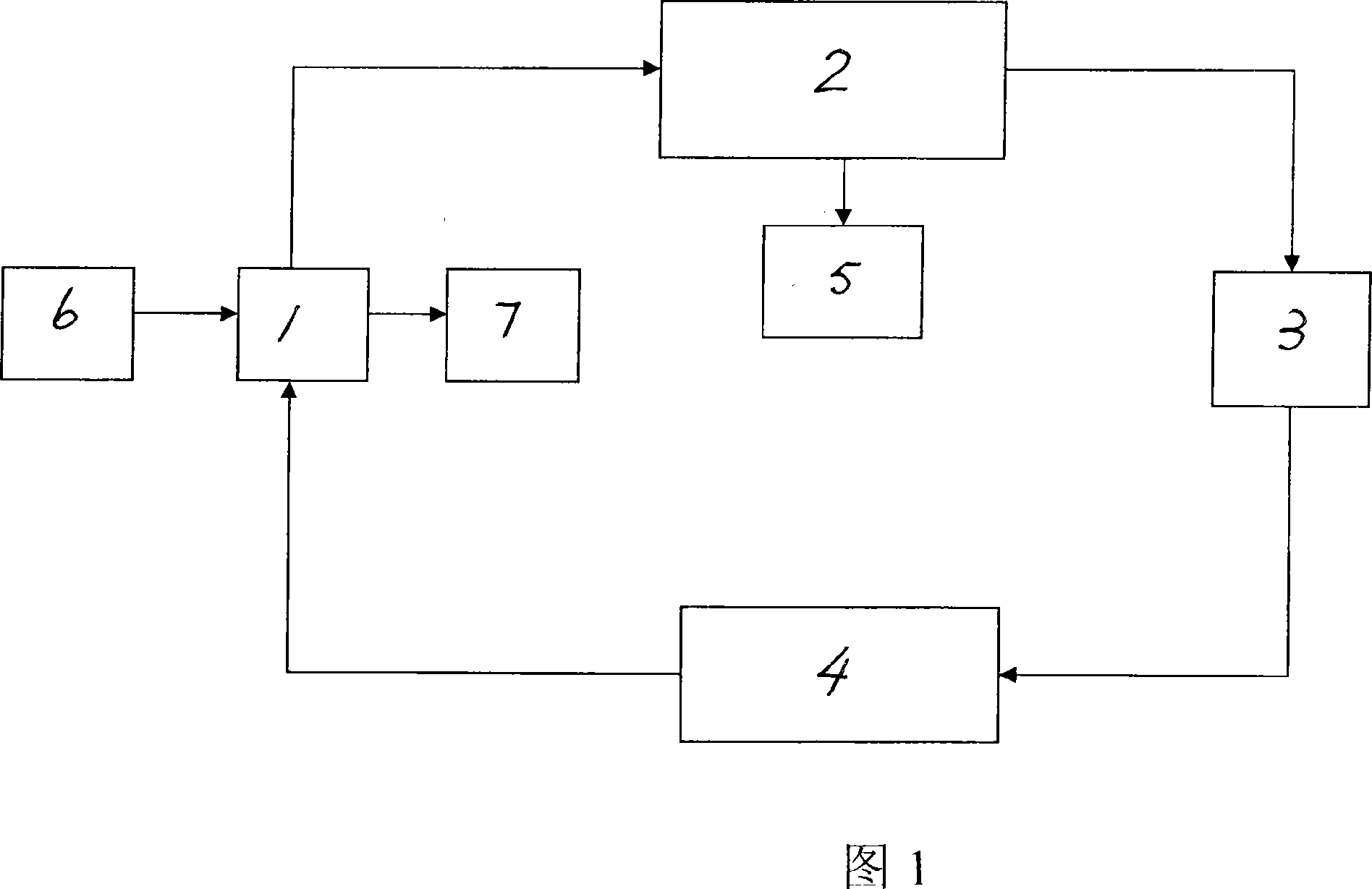

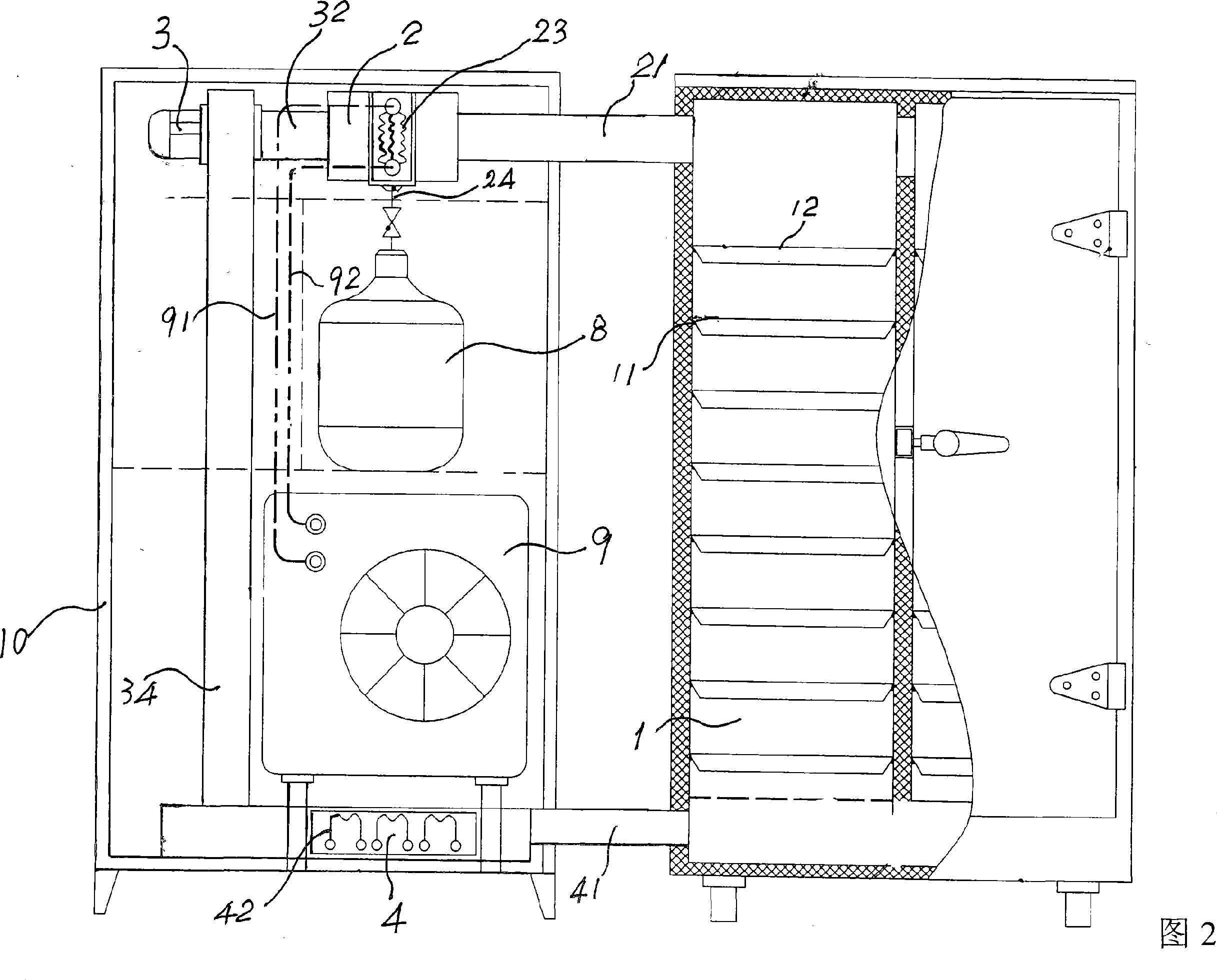

[0038] See Figure 1 and Figure 2,

[0039] An aromatic substance extraction device used in a dry method for extracting aromatic liquid and essential oil from aromatic plants, comprising a box body 10, which is provided with a heating chamber 4, an evaporation chamber 1, an extraction chamber 2 and a fan 3, The heating chamber 4 is connected to the evaporation chamber 1 through the pipeline 41, the evaporation chamber 1 is connected to the extraction chamber 2 through the pipeline 21, the extraction chamber 2 is connected to the fan 3 through the pipeline 32, and the fan 3 is connected to the heating chamber through the pipeline 34 4-phase connection to form a closed circulation pipeline device,

[0040] Said heating chamber 4 is provided with an electric heating tube 42, and the electric heating tube 42 is connected with a power supply,

[0041] Said evaporating chamber 1 is an airtight container, and the inner wall of the container is provided with a number of upper and lower ...

Embodiment 2

[0044] In April 2007, the applicant of this patent application used the aromatic substance extraction device of the present invention in Pingyin County, Shandong Province to carry out a productive test of the method.

[0045] Put 24 kilograms of rose buds in the tray 12 of the evaporation chamber 1, turn on the power supply of the heating chamber 4 and the fan 3, control the temperature of the hot air at 75°C, start working, turn on the refrigerator, work for 2 hours, and then the temperature of the hot air rises to 85°C ℃, for another 6 hours, the wind speed of fan 3 is controlled at 9 m / min, the inlet temperature of condensing pipe 23 is 8 ℃, and a large amount of aromatic substances evaporated in the evaporation box are condensed and dewed in condensing pipe 23, and discharged from the aromatic liquid and essential oil Pipe 24 collects 16 kilograms of extracted aromatic substances, and then, through an oil-water separator, separates aromatic liquid and essential oil, and col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com